4 Material

The material shall be one of the following: unplasticized poly(viny1 chloride) (PVC-U), polypropylene (PP) or polyethylene (PE), to which are added additives needed to facilitate the manufacture of components conforming to this document, including the relevant annexes.

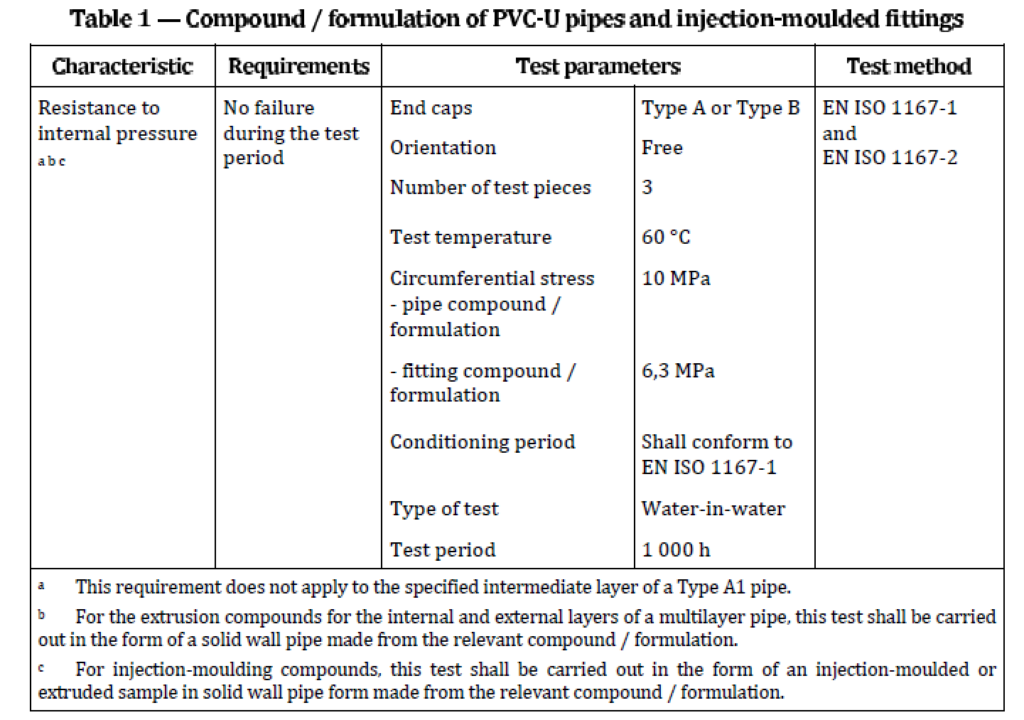

4.2 PVC-U

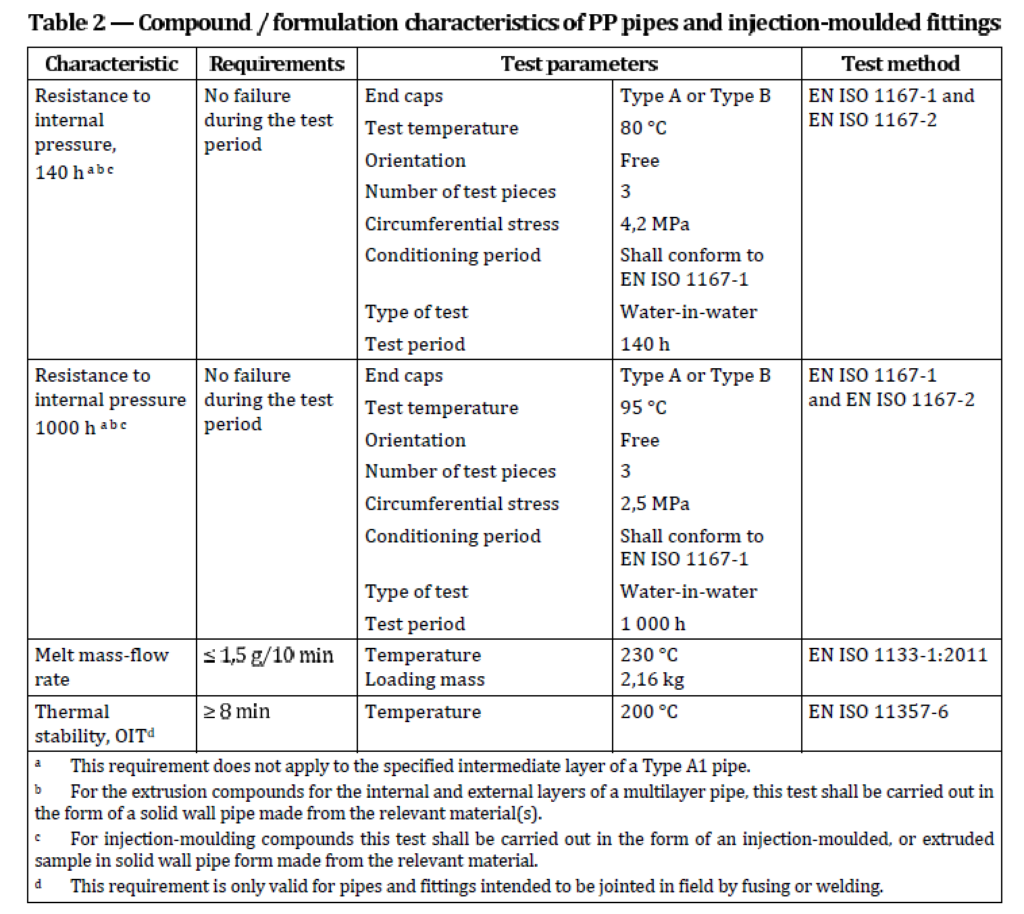

4.3 PP

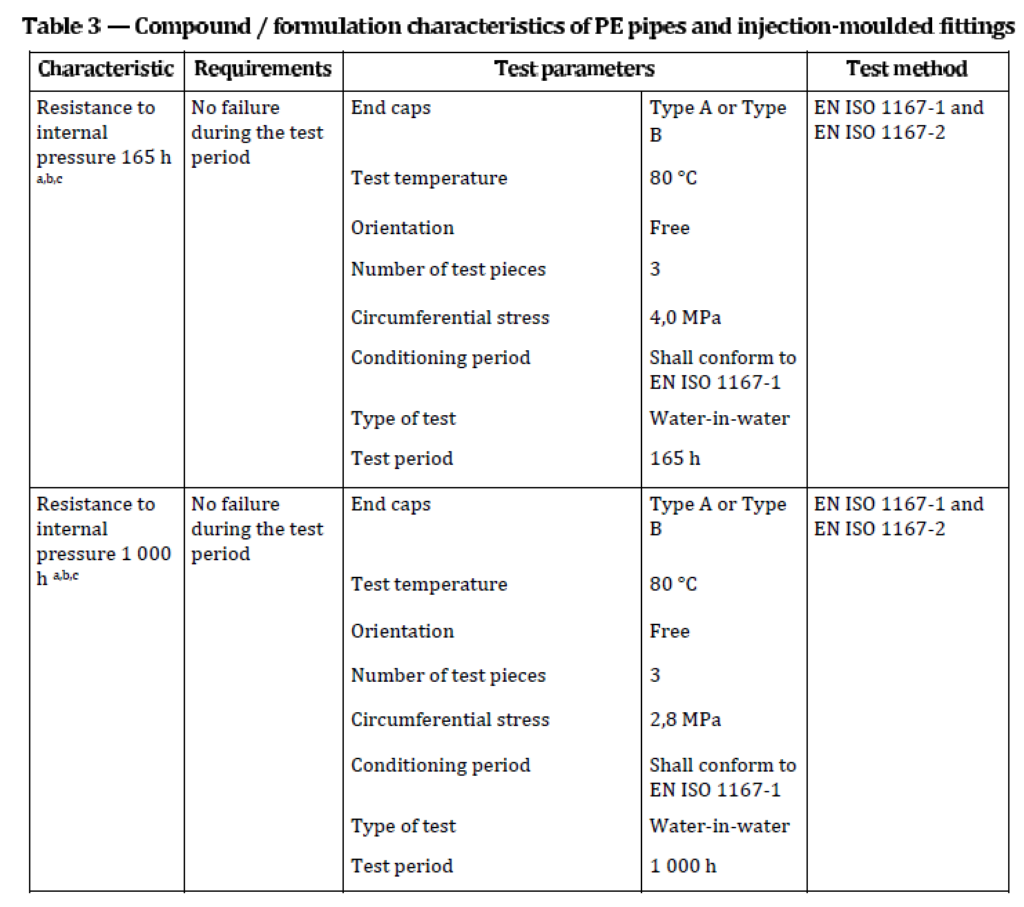

4.4 PE

8 Physical characteristics

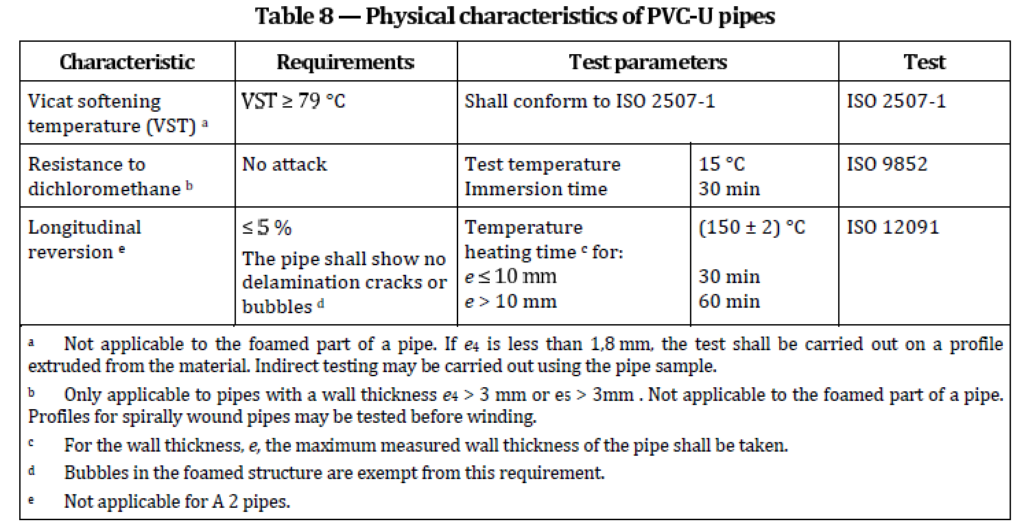

8.1 Unplasticized poly(viny1 chloride) (PVC-U)

8.1.1 Physical characteristics of PVC-U pipes

When tested in accordance with the test methods as specified in Table 8 using the indicated parameters, the pipe shall have physical characteristics conforming to the requirements given in Table 8.

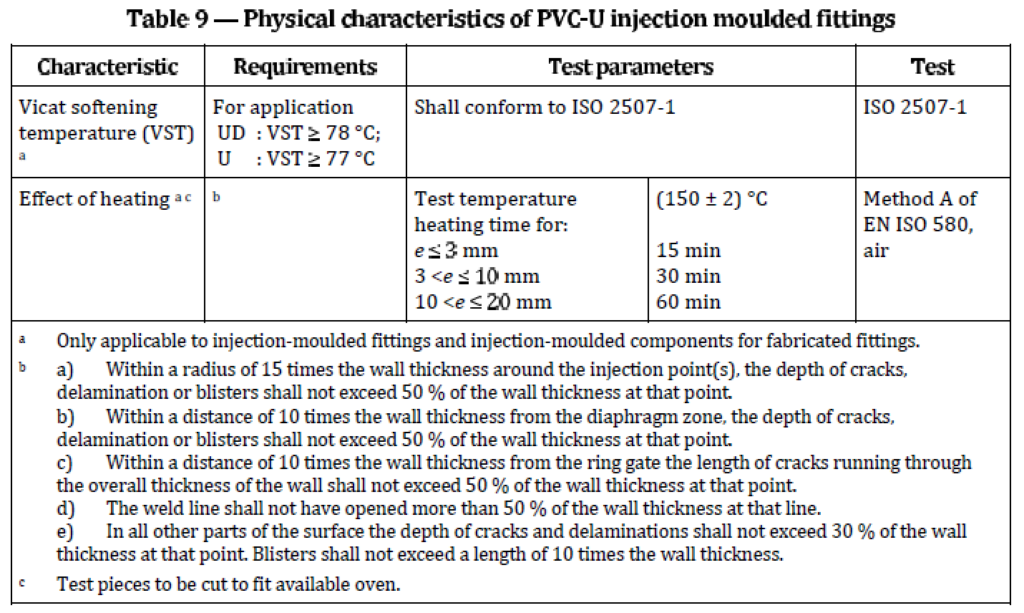

8.1.2 Physical characteristics of PVC-U fittings

When tested in accordance with the test methods as specified in Table 9 using the indicated parameters, the fitting shall have physical characteristics conforming to the requirements given in Table 9.

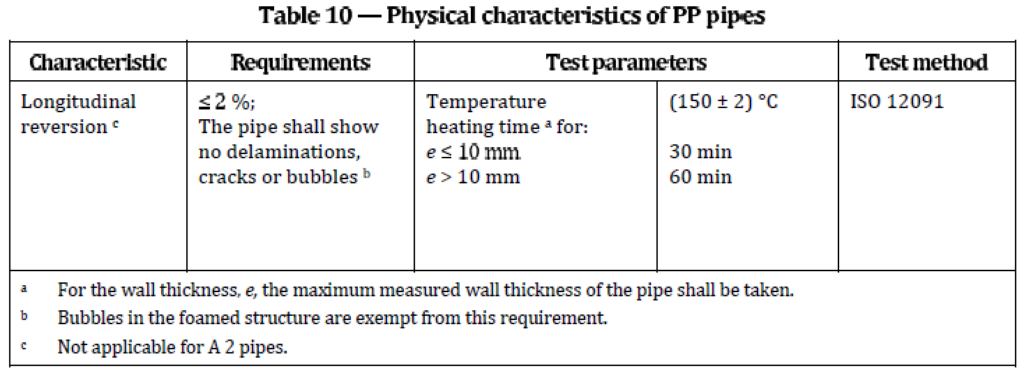

8.2 Polypropylene (PP)

8.2.1 Physical characteristics of PP pipes

When tested in accordance with the test methods as specified in Table 10 using the indicated parameters, the pipe shall have physical characteristics conforming to the requirements given in Table 10.

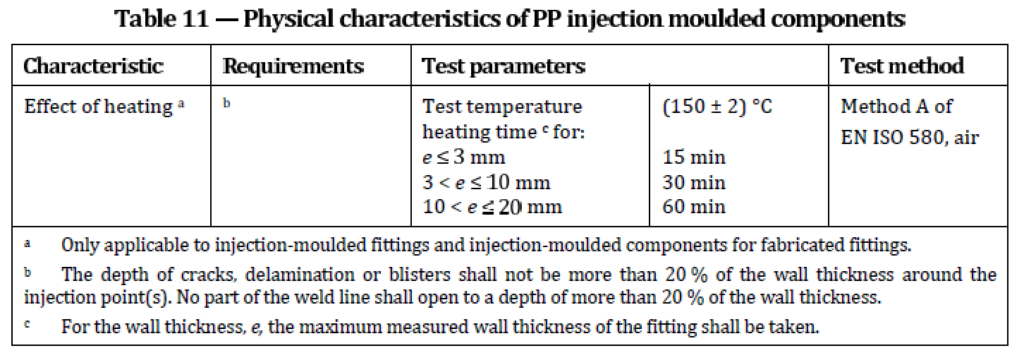

8.2.2 Physical characteristics of PP fittings

When tested in accordance with the test method as specified in Table 11 using the indicated parameters, the fittings shall have physical characteristics conforming to the requirements given in Table 11.

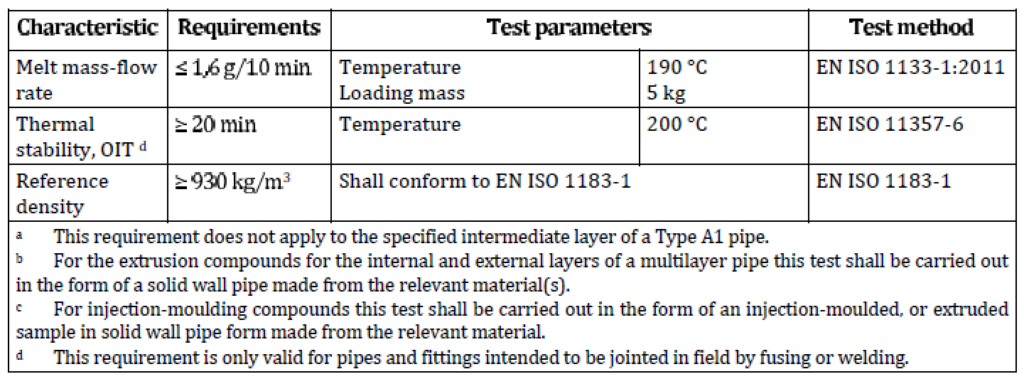

8.3 Polyethylene (PE)

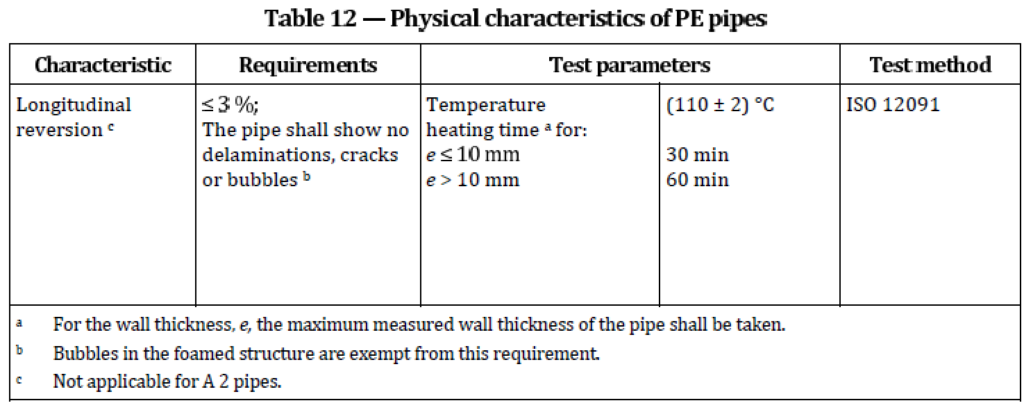

8.3.1 Physical characteristics of PE pipes

When tested in accordance with the test methods as specified in Table 12 using the indicated parameters, the pipe shall have physical characteristics conforming to the requirements given in Table 12.

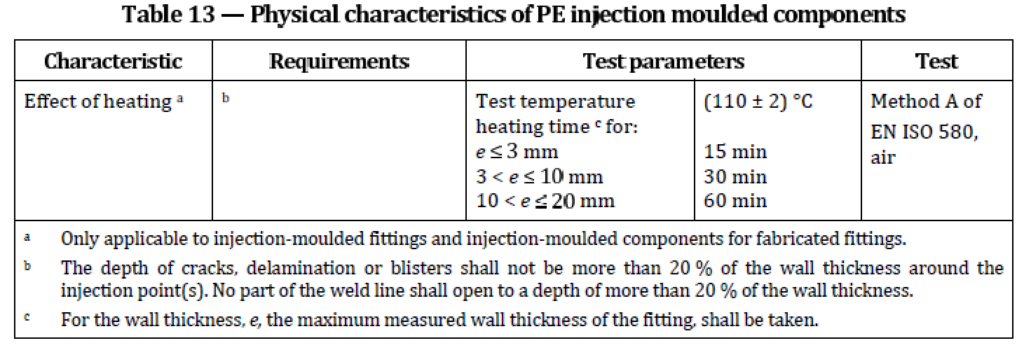

8.3.2 Physical characteristics of PE fittings

When tested in accordance with the test method as specified in Table 13 using the indicated parameters, the fitting shall have physical characteristics conforming to the requirements given in Table 13.

9 Mechanical characteristics

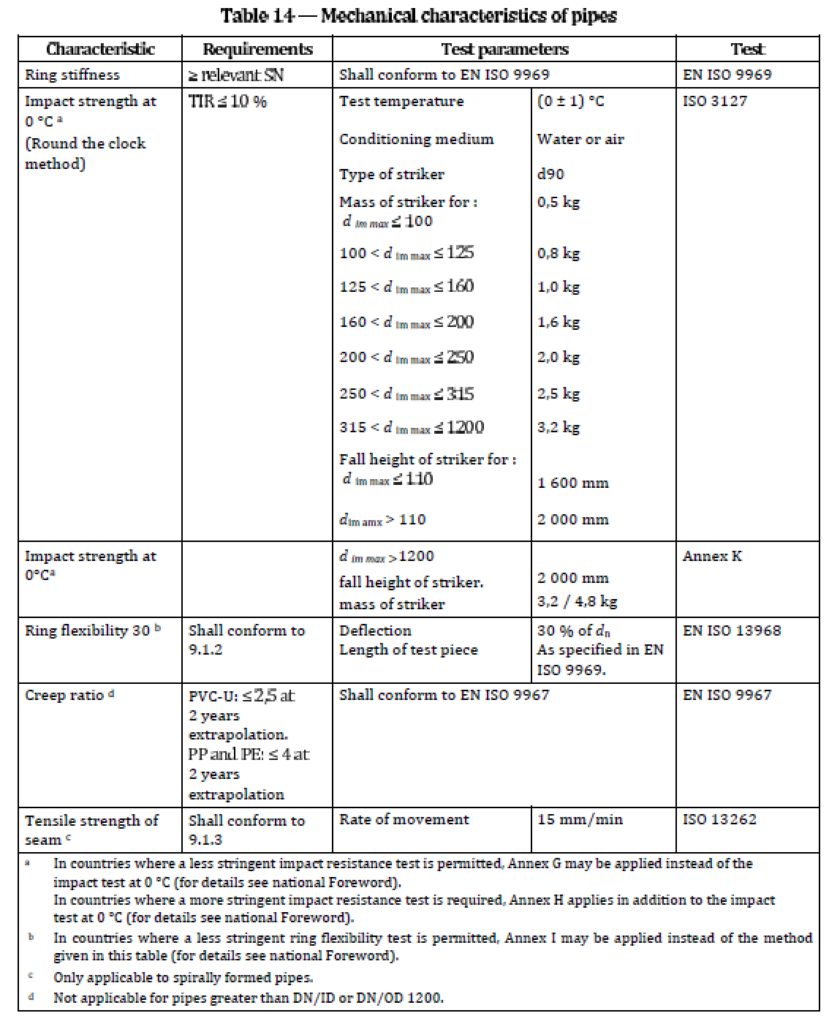

9.1 Mechanical characteristics of pipes

9.1.1 General requirements

When tested in accordance with the test methods as specified in Table 14 using the indicated parameters, the pipe shall have mechanical characteristics conforming to the requirements given in Table 14.

9.1.2 Ring flexibility

When tested in accordance with the test method as described in Table 15 using the indicated parameters and visually inspected without magnification, a) and b) shall be conformed to during the test:

a) there shall be no decrease of the measured force;

b) there shall be no cracking in any part of the wall structure. For spirally formed pipes, tears initiated along the cut of a rib shall not be considered as a failure if less than 0,075dem mm or 75 mm, whichever is smaller; and

C) to e) shall be conformed to after the test:

C) there shall be no wall delamination with the exception of possible delamination between the outside and inside wall of double wall pipes occurring in reduced welding zone in the ends of the test piece;

d) there shall be no other types of rupture in the test piece;

e) permanent buckling in any part of the structure of the pipe wall, including depressions and craters, shall not occur in any direction.

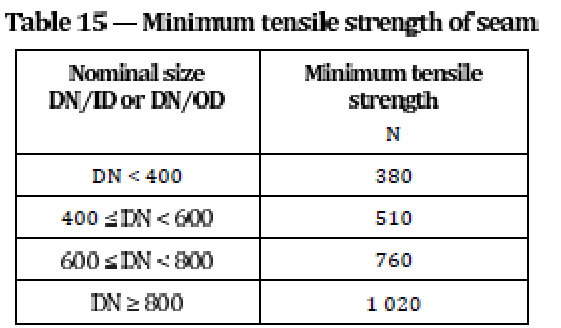

9.1.3 Tensile strength of seams (Type A.2)

When tested in accordance with Table 14 the minimum required tensile strength of the seam shall conform to Table 15.

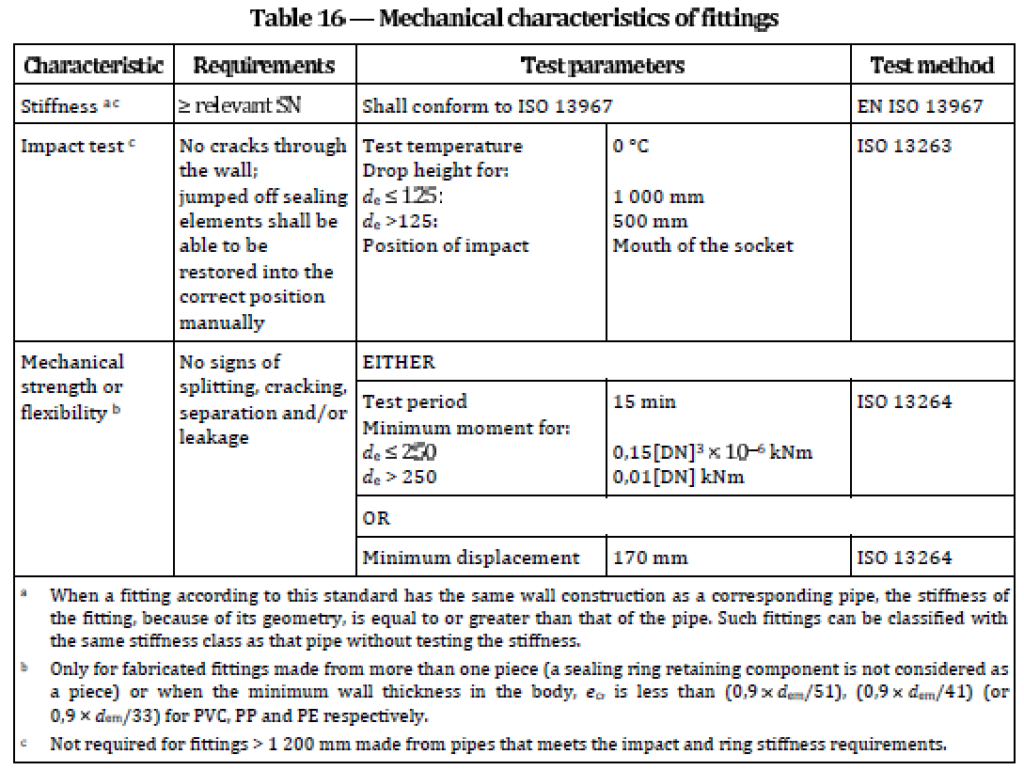

9.2 Mechanical characteristics of fittings

The mechanical characteristics of solid-wall fittings are described in the relevant product standards (EN 1401-1, EN 1852-1, or EN 12666-1) or prEN 13476-3.

For other fitting designs, the following apply:

When tested in accordance with the test methods as specified in Table 16 using the indicated parameters, the fitting shall have mechanical characteristics conforming to the requirements given in Table 16.

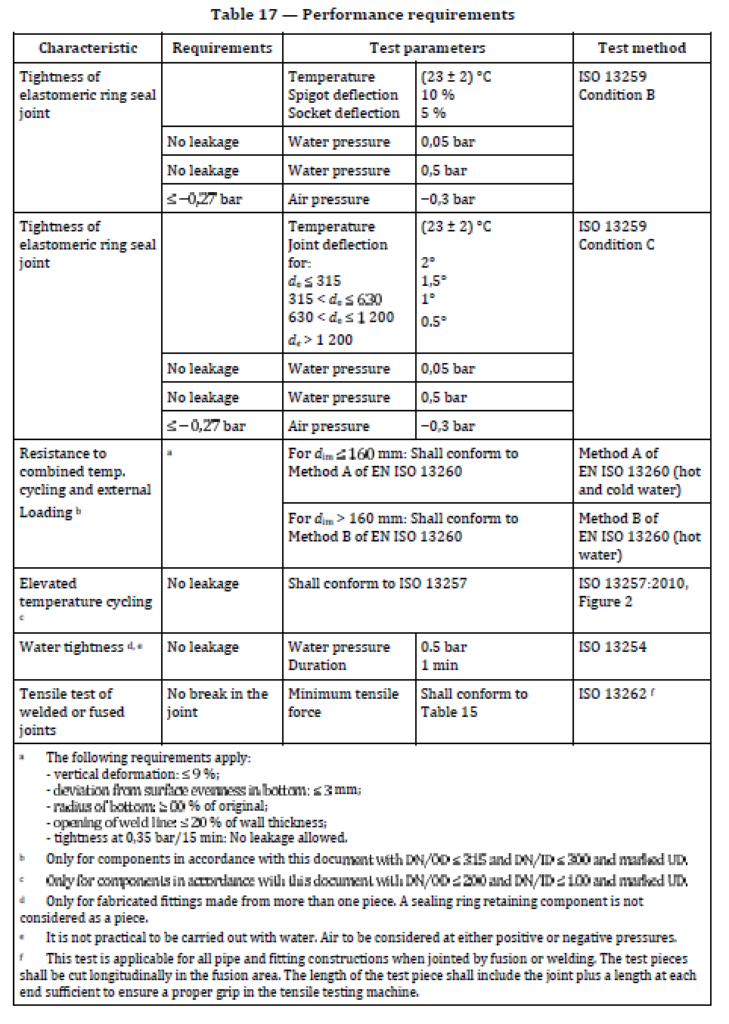

10 Performance Requirements

When tested in accordance with the test methods as specified in Table 17 using the indicated parameters, the joints and the system shall have characteristics conforming to the requirements given in Table 17.