8 Mechanical characteristics

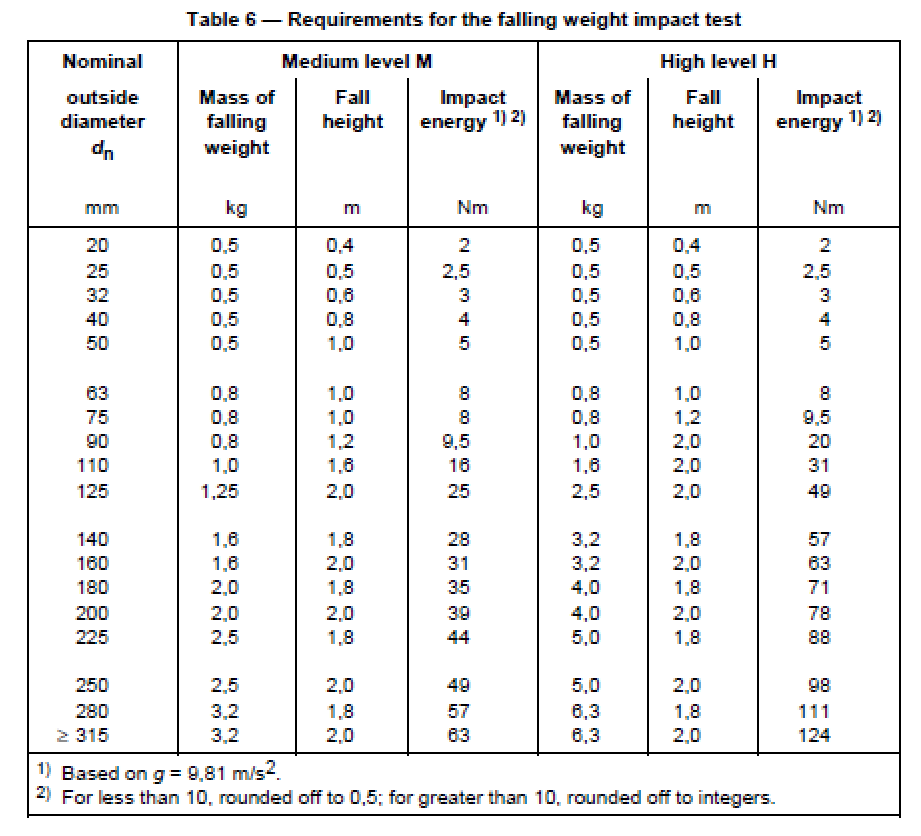

8.1 Impact strength

Pipes with a nominal wall thickness of 14,9 mm or less, when tested for resistance to external blows at 0 °C in accordance with EN 744:1995 shall have a true impact rate (TIR) of not more than 10 % when tested at the levels given in table 6.

Pipes in the series S 5 to S 10 shall be tested at the medium level M and pipes in the series S 12,5 to S 20

shall be tested at the high level H. The type of the striker shall be as given in table 2 of EN 744:1995 depending on the mass of the falling weight. The sampling procedure shall conform to ENV 1452-7.

NOTE For practical reasons this test is not relevant for pipes with dn < 20 mm.

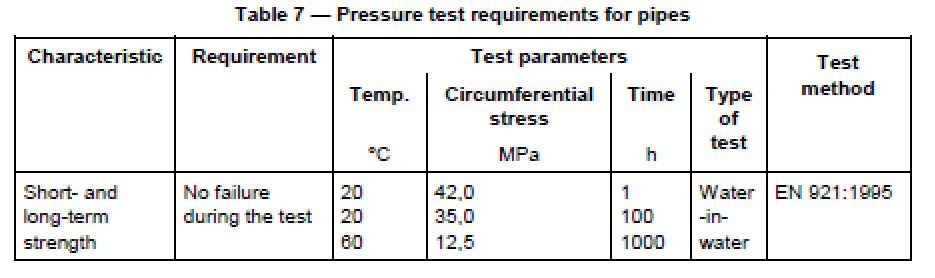

8.2 Resistance to internal pressure

Pipes shall withstand without bursting or leakage the hydrostatic stress induced by internal hydrostatic

pressure when tested in accordance with EN 921:1995 using the test conditions specified in table 7.

For this test end caps type a) or b) in accordance with EN 921:1995 may be used.

The sampling procedure shall conform to ENV 1452-7.

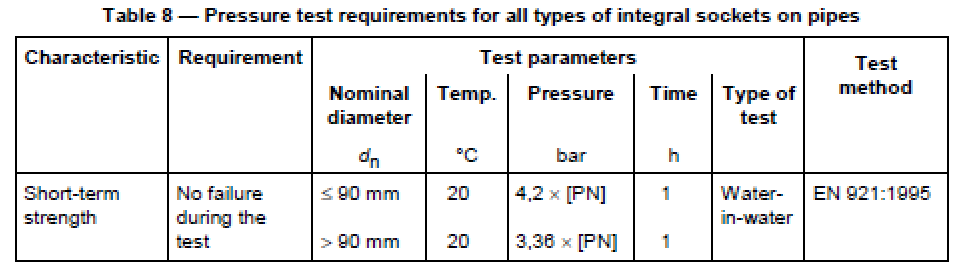

Integral sockets shall be tested in accordance with EN 921:1995 using the test parameters given in table 8.

For this test end caps type a) or b) in accordance with EN 921:1995 may be used and the socket entrance

may be externally reinforced to prevent a displacement of the sealing ring. The sampling procedure shall

conform to ENV 1452-7.

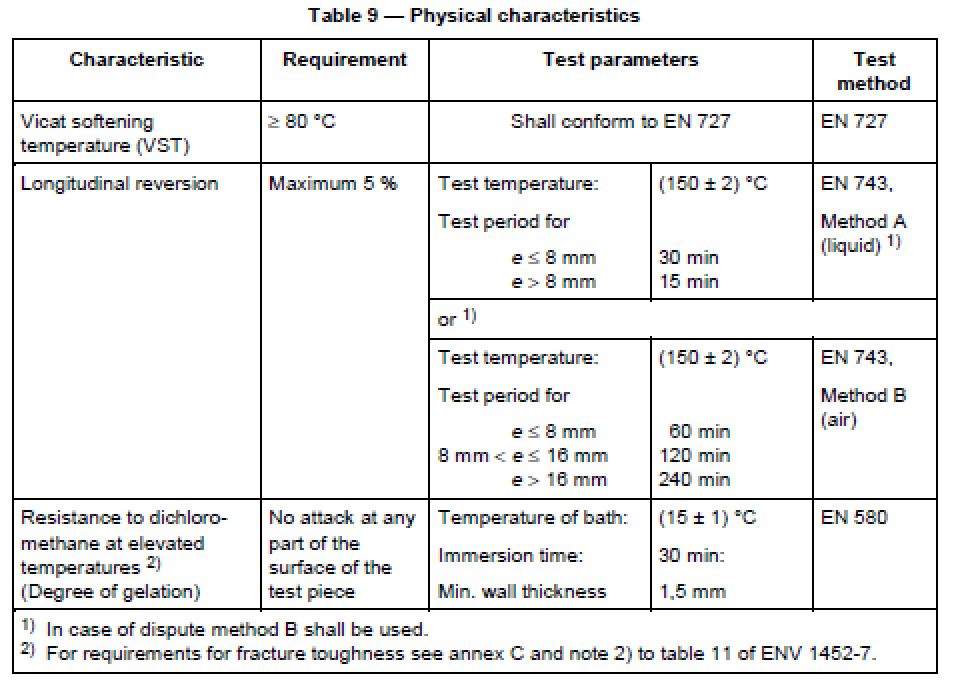

9 Physical characteristics

When tested in accordance with the test methods as specified in table 9 using the indicated parameters, the pipe shall have physical characteristics conforming to the requirements given in table 9.

The sampling procedure shall conform to ENV 1452-7.

10 Chemical characteristics

The PVC-U pipe shall not contain vinyl chloride monomer (VCM) exceeding 1 ppm when determined by

means of gas-phase chromatography using the ‘headspace’ method according to ISO 6401. The sampling

procedure shall conform to ENV 1452-7.

11 Sealing rings

The material of the elastomeric sealing ring used in joint assemblies for pipes shall be chosen from EN 681-1

12 Adhesives

The adhesive(s) shall have no detrimental effects on the pipe and shall not cause the test assembly to fail to conform to EN 1452-5.

The adhesives shall be identified according to ISO 7387-1 and their properties shall conform to the

appropriate standards.

NOTE A standard on a test method for the determination of the film properties is under preparation (see

prEN ISO 9311-1) and shall conform to the appropriate class.

The sealing ring shall have no detrimental effect on the properties of the pipe and shall not cause the test

assembly to fail the functional requirements of EN 1452-5.

13 Performance requirements

When pipes conforming to this standard are jointed to each other or to components conforming to other Parts of EN 1452, the pipes and the joints shall conform to EN 1452-5.

Below, You Will Find Links to the Products Page of the Required Testing Equipment to Cover This Standard