First lets take a look at the tests need to be done on the pipe itself according to this norm:

5 General characteristics

5.1 Appearance

When viewed without magnification the internal and external surfaces of pipes shall be smooth, clean and free from scoring, cavities, and other surface defects to an extent that would prevent conformity to this standard.

The material shall not contain visible impurities. Slight variations in appearance of the colour are permitted. The ends of the pipe shall be cut cleanly and square to the axis of the pipe.

5.2 Opacity

Polypropylene pipes that are declared to be opaque shall not transmit more than 0,2 % of visible light, when tested in accordance with ISO 7686.

6 Geometrical characteristics

Besides above specification for general characteristics and geometrical characteristics we have below mechanical, physical and chemical characteristics:

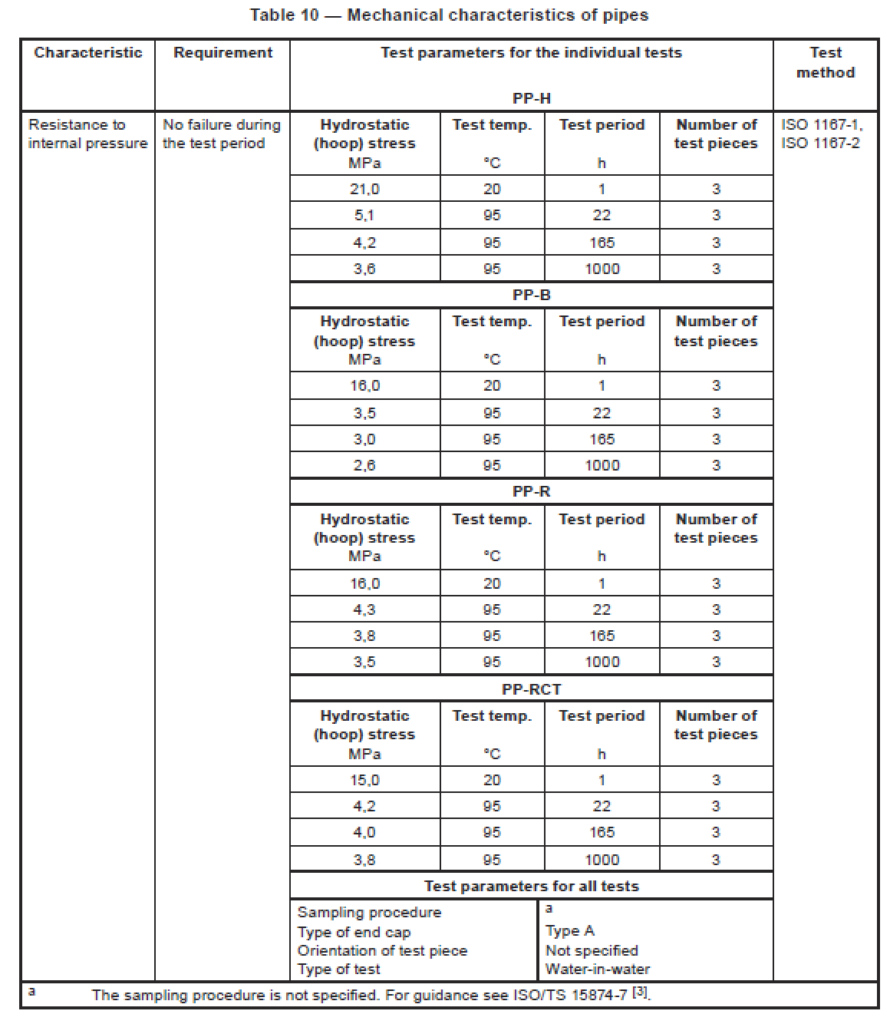

7 Mechanical characteristics

When tested in accordance with the test methods as specified in Table 10 using the indicated parameters, the pipe shall withstand the hydrostatic (hoop) stress without bursting. In the case of pipes with (a) barrier layer(s) the test shall be carried out on test pieces produced without the barrier layer(s).

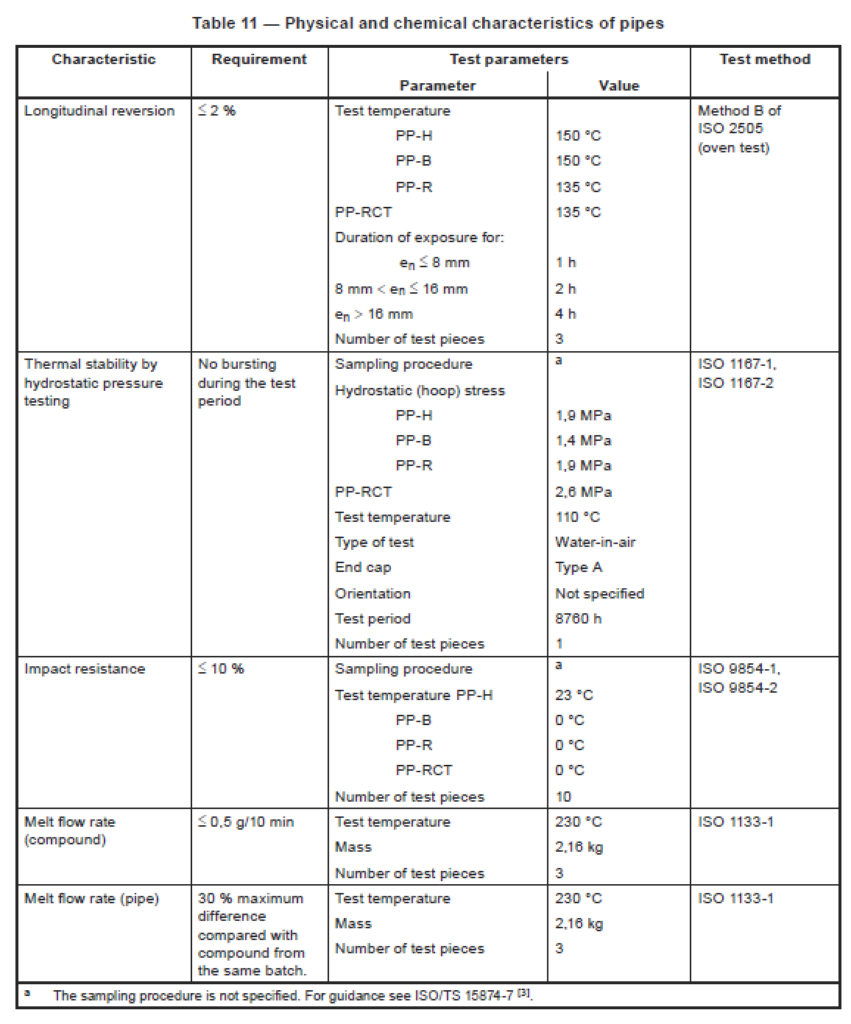

8 Physical and chemical characteristics

When tested in accordance with the test methods as specified in Table 11 using the indicated parameters, the pipe shall conform to the requirements given in this table.

Above writings from ISO 15874 shows there is no tensile testing defined for performance of the pipes according to this norm.

Customer wants to do tensile testing according to ISO 6259 for his own reserach purposes. Lets see what it tells us:

This standards has 3 parts:

Thermoplastics pipes — Determination of tensile properties — Part 1:General test method

Thermoplastics pipes — Determination of tensile properties — Part 2: Pipes made of unplasticized poly(vinyl chloride) (PVC-U), oriented unplasticized poly(vinyl chloride) (PVC-O), chlorinated poly(vinyl chloride) (PVC-C) and high-impact poly(vinyl chloride) (PVC-HI)

Thermoplastics pipes — Determination of tensile properties — Part 3: Polyolefin pipes

Then we are going to check part 3 for “Polyolefin pipes“.

1 Scope

This part of ISO6259 specifies a method of determining the tensile properties of polyolefin (polyethylene,

cross-linked polyethylene, polypropylene, and polybutene) pipes, and the following properties:

— the stress at yield;

— the elongation at break.

This part of ISO 6259 also gives the corresponding basic specifications in Annexes A to D for information

purposes only.

5 Apparatus

See ISO 6259-1:2015, Clause 5, applicable to thermoplastics materials covered by this part of ISO 6259.

6 Test pieces

6.1 Selection of the test pieces

6.1.1 General

The test pieces shall be obtained by die cutting or machining.

NOTE 1 When the thickness of the pipe is less than or equal to 12 mm, the test pieces are to be die cut preferably.

NOTE 2 Care ought to be taken when using die cutting to avoid damaging the test specimen or producing non parallel sides.

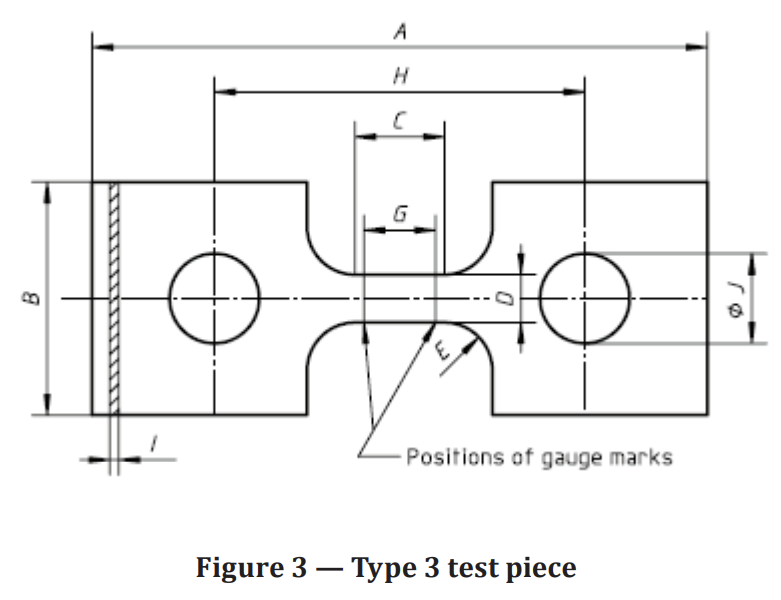

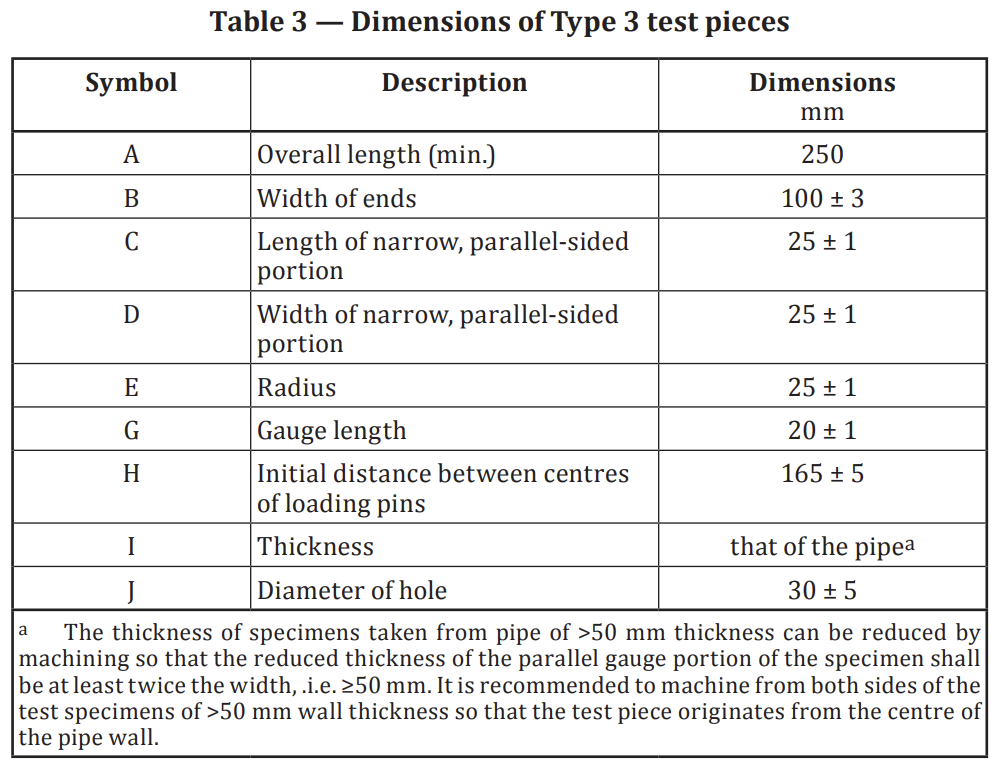

6.1.2 Dimensions of test pieces

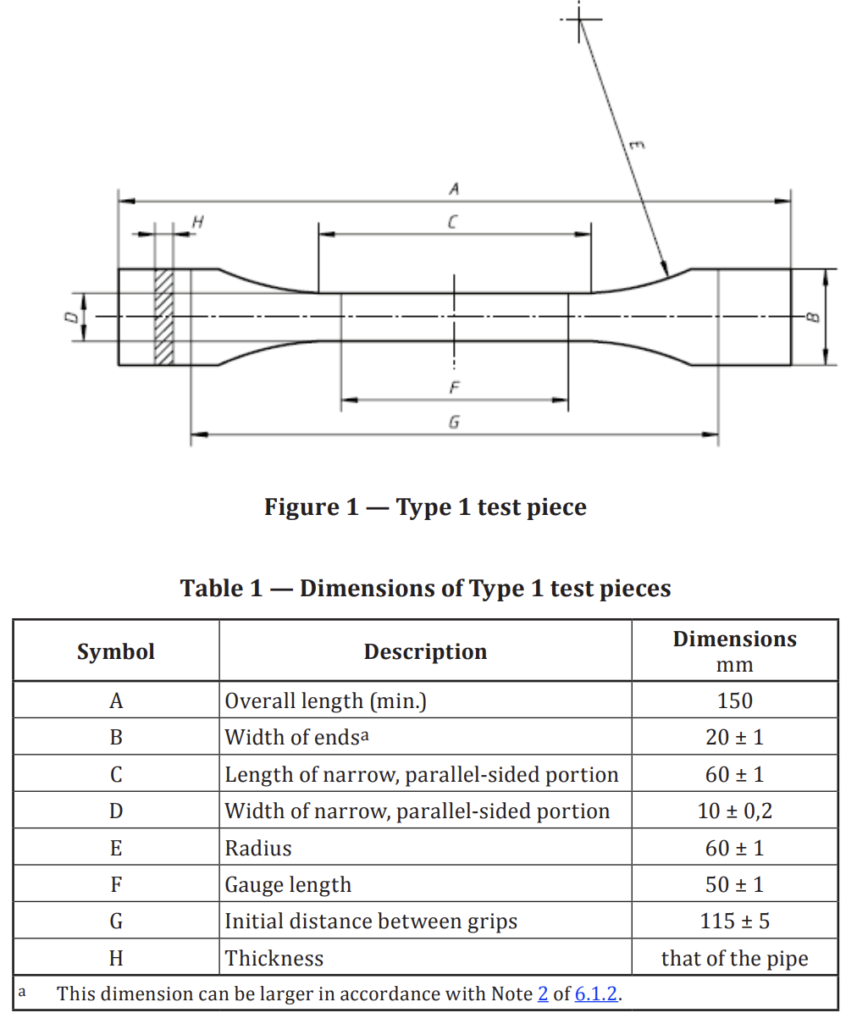

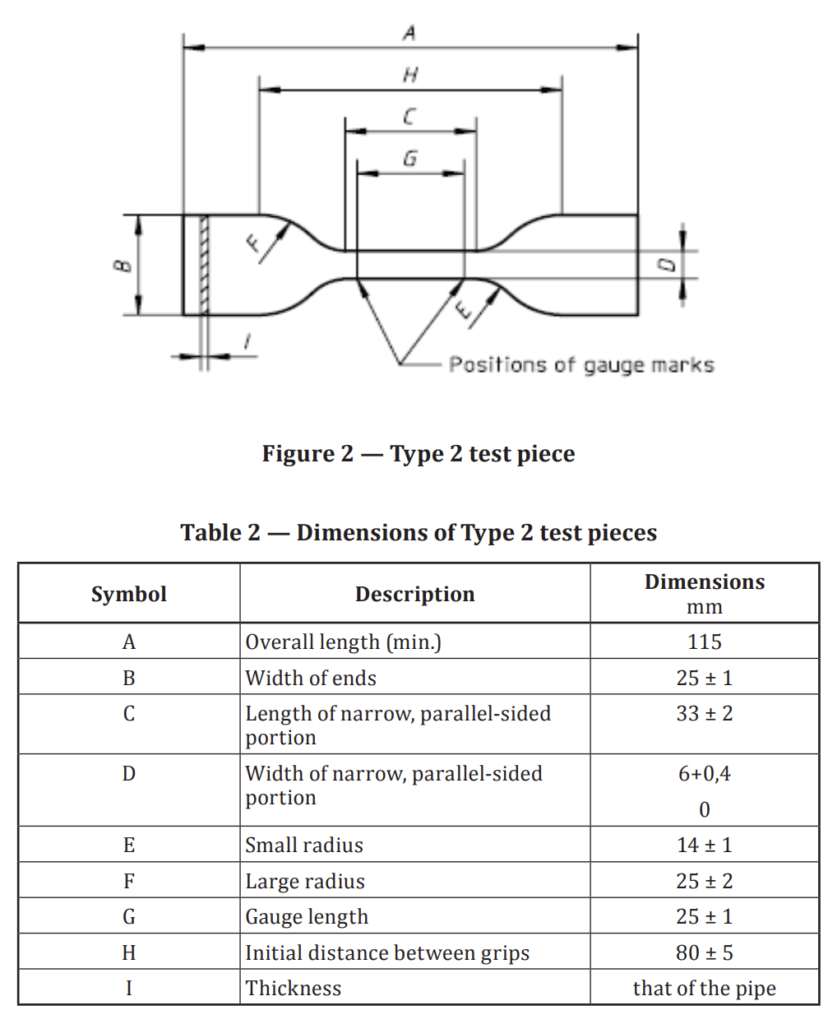

Test pieces shall be either of Type 1, the shape and dimensions of which are given in Figure 1 and Table 1,

Type 2, the shape and dimensions of which are given in Figure 2 and Table 2, or Type 3, the shape and

dimensions of which are given in Figure 3 and Table 3. The choice of test piece is dependent on the wall

thickness of the pipe from which it is taken (see 6.2).

NOTE 1 The Type 1 test piece is identical to the Type 1B specified in ISO 527-2 [1]. The Type 2 test piece is

identical to the Type 2 specified in ISO 6259-2 [2]. The Type 3 test piece is identical to the Type B test piece in ISO 13953 [3].

NOTE 2 In order to avoid slippage in the grips, it is recommended that the width of the ends of the test piece (B) be increased in proportion to the thickness (en) in accordance with Formula (1):

B = en + 15 (mm) (1)

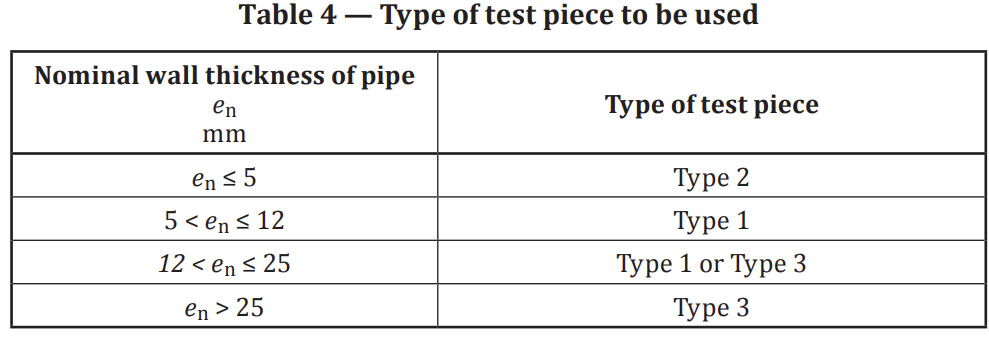

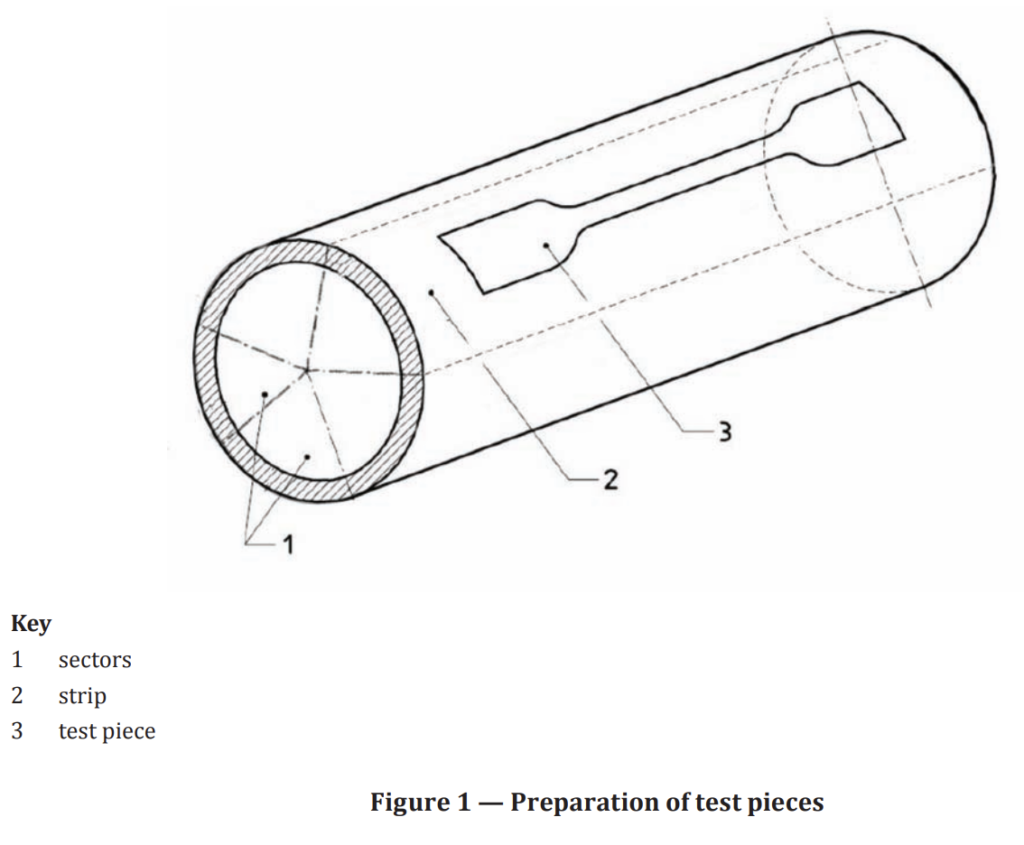

6.2 Preparation of test pieces

The test pieces shall be taken from the centre of strips cut from the length of pipe in accordance with

ISO 6259-1:2015, 6.2.1. The type of test piece shall be selected according to the thickness of the pipe as

shown in Table 4.

6.3 Cutting method

Use a cutting die with a profile corresponding to that of the Type 1 or Type 2 test piece, depending on

thickness of the pipe, see ISO 6259-1:2015, 5.6.

Cut out the test piece at ambient temperature, applying the die cutter to the inner surface of the strip

and exerting a continuous uniform pressure.

Customer has 32mm outer diameter pipe and need to do tensile testing according to ISO 6259-2. According the above comments if the thickness of pipe is between 5 and 12mm then we need to choose sample type 1. the thickness of pipe he choose is 5.4 mm, then we need to cut samples according to type 1. Lets take a look at ISO 6259-1 general test method about how to cut this sample type 1 from a pipe that has 32mm outer diameter and 5.4mm thickness.

6 Test Pieces

6.1 Type of the test piece

The test pieces shall conform to the relevant type specified in ISO 6259-2:1997 or ISO 6259-3:2015 or

the relevant product standard, as applicable.

6.2 Preparation of test pieces

6.2.1 Sampling from the pipe

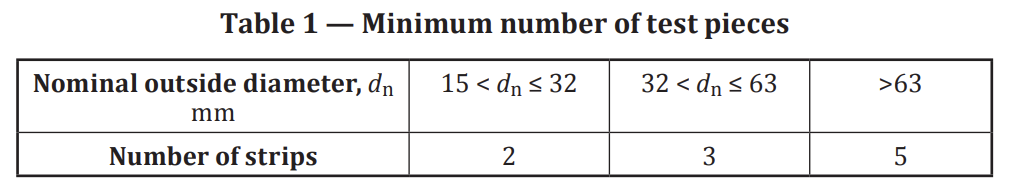

Take sections of pipe of the appropriate length according to the type of test piece to be used.

Cut strips from the pipe section as supplied, i.e. which has not been heated or flattened, so that their

axes are parallel to the axis of the pipe. Small diameter pipes might need to be cut and opened to allow

the strips to be cut.

Cut strips from the pipe section in such a way that they are equally distributed around the circumference

of the pipe as shown in Figure 1, starting from a reference line drawn along the pipe. Cut out one test

piece per strip.

The minimum number of test pieces is given in Table 1. When it is not possible to obtain the required

number of strips from around the circumference of one pipe section, additional strips shall be taken

from another section of the pipe.

6.2.2 Selection of test pieces

6.2.2.1 Selection

Select the test pieces from the centre of the strips taken from the length of pipe either by die cutting or

machining, in accordance with ISO 6259-2:1997 or ISO 6259-3:2015 or relevant product standard, or in

accordance with the appropriate product standard for the pipe material.

6.2.2.2 Cutting method

Use the cutting die (5.6) with clean cutting edges, free from notches, with the profile shown in

ISO 6259-2:1997 or ISO 6259-3:2015, as applicable.

Cut the test piece from the strip (see 6.2.1).

Care should be taken when using die cutting to avoid damaging the test piece or producing non-parallel sides.

6.2.2.3 Machining method

Produce the specimen by milling, where necessary, using a milling jig.

The shape of the milling cutter and the machining conditions (speed of rotation and advance) are at the

discretion of the operator. They shall, however, be chosen so as to avoid excessive heating of the test

piece and deterioration of its surface such as cracks, scratches, or other visible flaws.

For the machining procedure, it is recommended that the user consult ISO 2818[3].

Based on above comments i am proposing our valued customer to cut the 32mm pipe in two pieces (according to table 1-ISO 6259-1) in length. pointing him to section 6.2.1 of ISO 6259-1 “Small diameter pipes might need to be cut and opened to allow the strips to be cut“. After cutting, need to open two pieces so that we can cut sample pieces of width 20mm (that is for type 1) from those opened pieces.