Description

- Injection volume: 20 cm3

- Operating temperature: up to 35O °C

- Power: 400W- 220V

- Easy mold change

- Tunable head

- No need of any moving parts for charging the cylinder (compare to other brands)

- Filling the reservoir of material rapidly and easily

- Material reservoir with cooling action

- Robust cast iron structure guaranties no movement of parts during injection

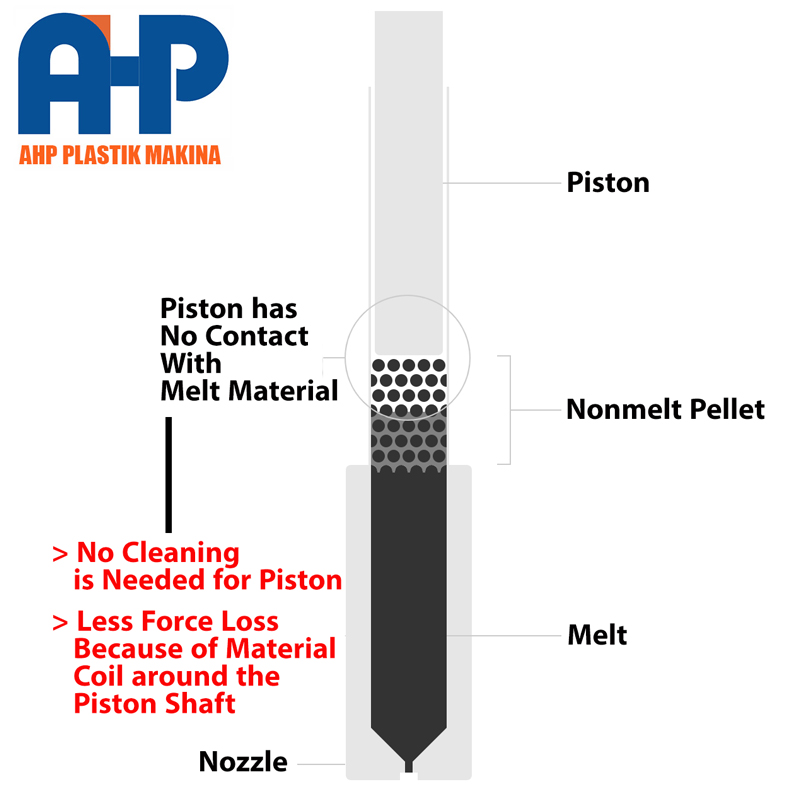

- No need to clean the piston every time because it has no touch of molten material

- Pressure application of molten material with no touch of piston head with molten material

- Production rate: 1 to 2 min/parts depending on the volume to be injected and the type of thermoplastic and modules used

- No force application on the mold

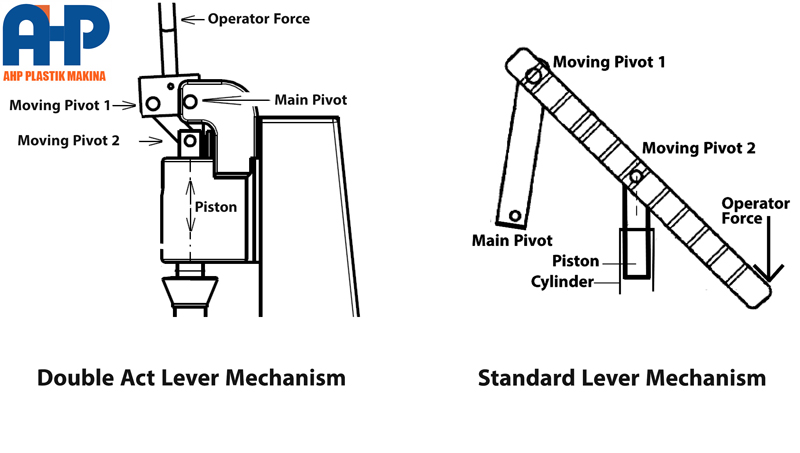

- Doubled the force compare to the present models in the market

- No moving parts for charging the cylinder

- Half price compare to the other brands in the market

- Easy change of direction of handle for left hand people

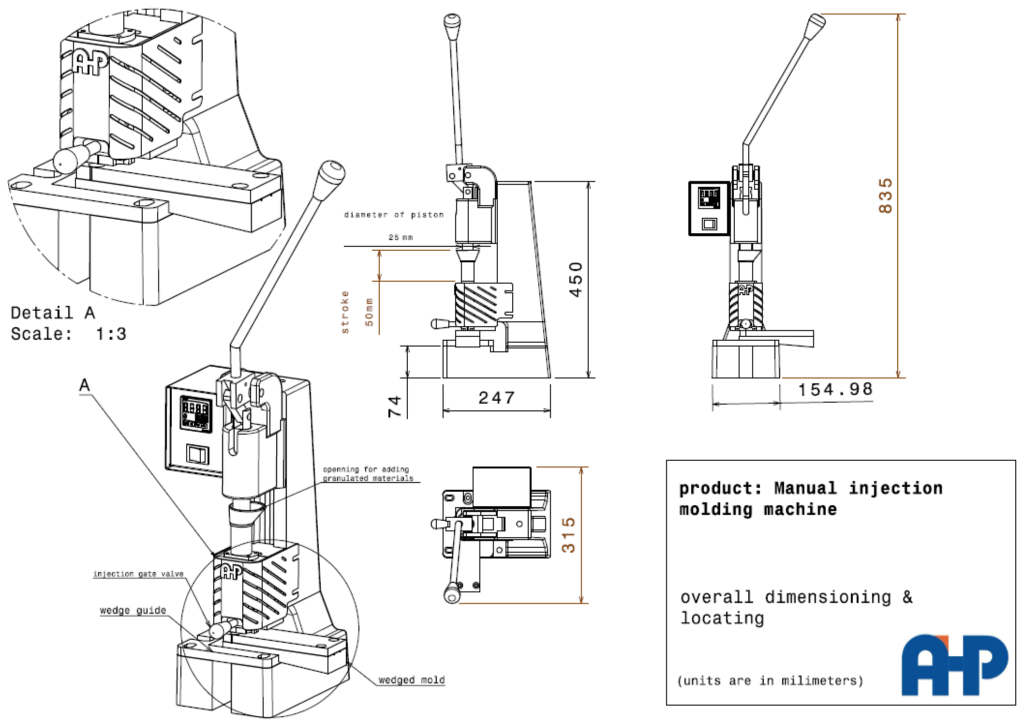

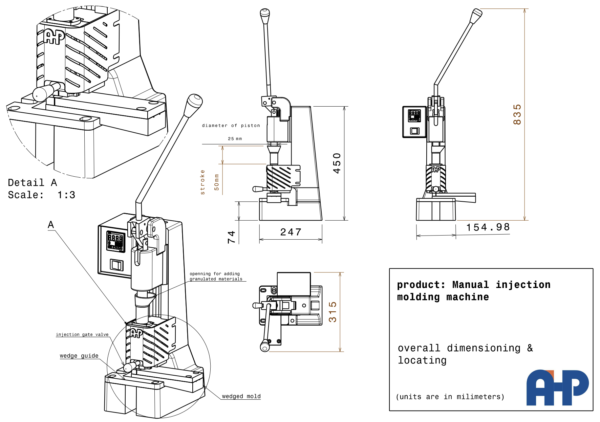

- Piston diameter: 20mm (Thanks to special design for lever make it possible of doubling the force compare to other brands in the market and make it possible for higher volume of material to be injected)

- Reservoir for granule material with cooling action

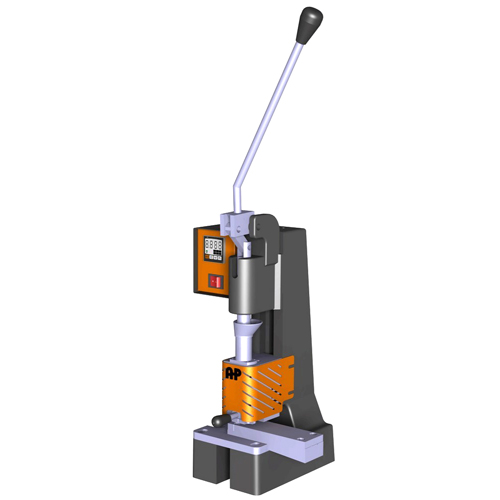

- PID temperature controller

- Special nozzle design with contact face instead of conical contact reducing stress and material release on contact face with the mold

- Valve on the nozzle make it possible to compress material before injection for air bubble release

- Controller box attached to the body for easy setting

- No movement of cylinder is needed during injection, compare to other brands

- No grip is needed for placement of mold under injection

- Can be supplied with aluminum molds as per customer request

- Proper choice even for low flow-high MFI value materials for industrial purposes

- Replaceable cylinder for different material

- Easy clean of cylinder because it is easy to detach from the machine body

- Cleaning brush coming with machine

- Double act lever mechanism increase the molding force two times compare other brands while keeping the lever length shorter

- You can even injection mold with materials like HDPE with low MFI of about 0.18 g/10 min for laboratory samples

- Safety gloves included

- Molds can be supplied with materials of customer request such as Steel, aluminum, copper, dense wood

- Compatible with different polymer materials like PEDH, LDPE, PP, PLA, PS, PA, TPU, POM, ABS, PMMA

| Parameter | New Version of AHP | Others |

| Injection volume | We used a 20mm Cylinder and a bigger shot size, even with reduced travel (It has 20cc of shot volume) | Using a cylinder of 16mm because of not being able to inject material in a cylinder with a bigger diameter, due to limitations on force application, and a weak body (Most of them are less than 12 cc) |

| Force Value (Kg) | 1000 KG | Most of them are less than 500 Kg (This force is applicable with hanging a man of 100 Kg with the lever of the machine with a ratio of 5/1). In most of the machines, this lever ratio is even around 4. Meaning maximum force is up to 400 Kg. |

| Reservoir | It has a reservoir with cooling, no moving parts, no melting of material inside the reservoir, and no moving parts of the head to fill the cylinder | Most of them have no reservoir, or a reservoir in contact with the hot section causes melting of some of the material inside the reservoir, with no cooling, or a reservoir that needs moving parts of the head (translation or rotation of the head) to be able to fill the cylinder |

| Force application | Double-act lever, doubled the force value | Standard lever |

| Mold grip | No mold grip, thanks to the wedge application | Manual mold grip, opens on injection of low MFI materials or higher force application |

| Injection speed | Lower travel of the piston, bigger diameter guarantees a higher injection speed and complete filling of the mold, even with low-MFI materials | Lower diameter, higher travel of the piston, on different models of lever and wheel mechanisms, causes lower injection speed. Lower speed causes solidification of the material, especially on low-flow materials inside the mold, before complete filling. |

| Shot size | 20 cc | Mostly 10-16 cc |

| Charging the cylinder | Thanks to the cooled hopper, it makes it possible to multiple-shot with no charging needed in every shot | Moving parts of the head are available, a waste of time, and charging is needed for every shot of injection. |

| Compaction of material | It is available because of the nozzle with a valve | Not available and cause samples with air bubbles |

| Lever mechanism | Double-act mechanism, higher force, lower travel, lower lever length | Standard lever, long lever requires much effort for the operator |

| Structure | Cast a robust structure | Aluminum table and body, iron sheet metal working |

| Injection speed | Higher speed because of the bigger diameter, of less travel in the injection section | Less speed, because of higher travel of the piston, direct contact of the piston and molten material. Material slipping around the piston head and shaft causes friction between the molten material and the piston shaft, less force being applied to the molten material. Prolonged lever length causes lower speed. |

| MFI range suitable for injection | All ranges of material MFI is possible specially for industrial purposes and industrial laboratory applications. | Absolutely impossible to inject very low MFI materials for industrial purposes. Most of them are only suitable for general-purpose uses in home applications. |

Melt Material Has No Contact With Piston and Rod

Double Act Lever Mechanism

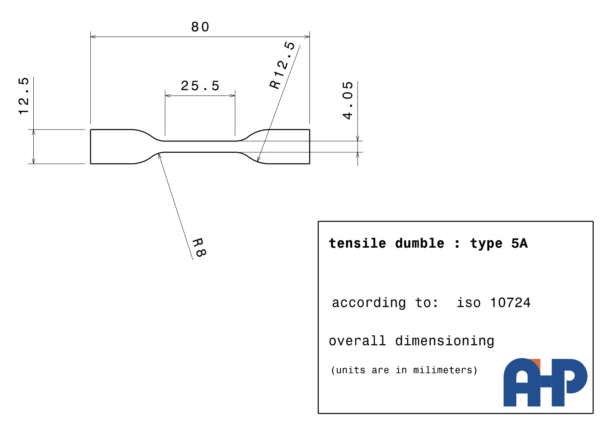

Positioning of the pivots are in such a way that it increases force as it moves forward, compare to standard lever that you have reduction of force as operator hand moves forward. It guaranties the complete filling of the mold specially with low MFI materials for industrial laboratory purposes of tensile, Izod, Charpy, …

At the end of the injection cycles it makes it easy to keep the compaction force for cooling of sample with no formation of air bubbles on samples that is very critical specially for laboratory samples. This is because of special linkage design.

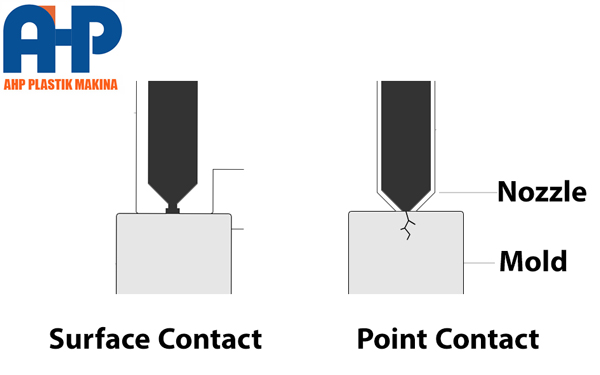

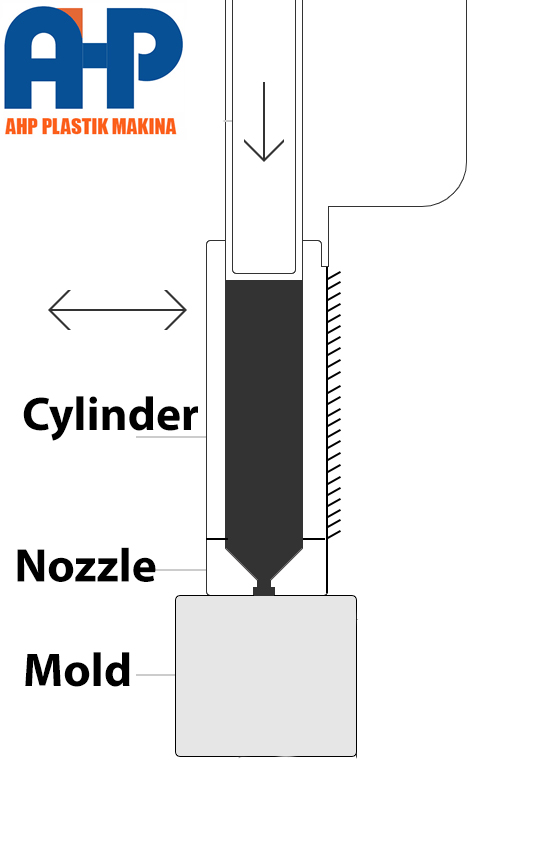

Contact of Nozzle to the Mold

Surface contact makes it possible to have fix cylinder with no need for movement during injection. Less damage to the mold and much more seal during injection. Sealing makes it possible to have less material mess on the mold.

It also makes it possible to have insertion of the mold from the side.

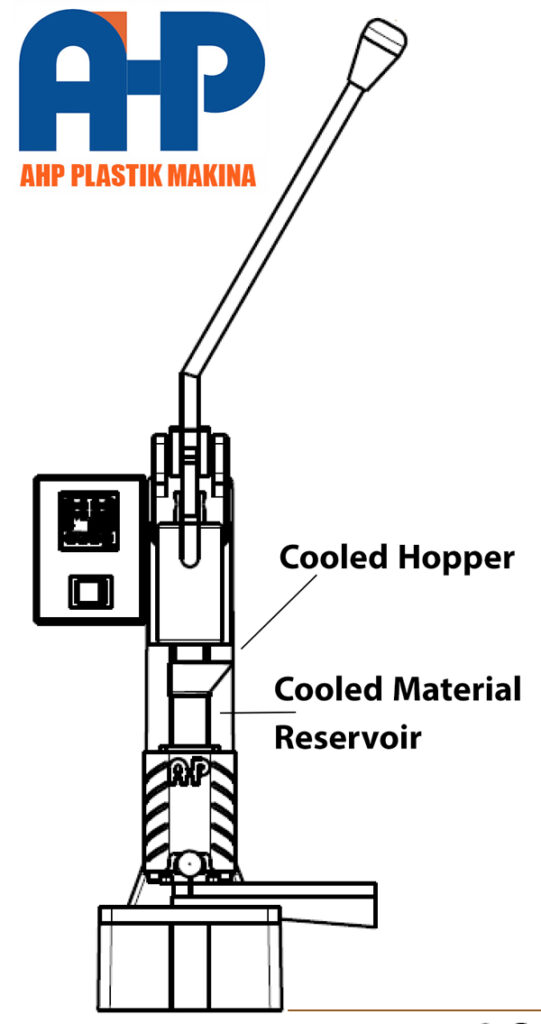

Cooled Hopper and Material Reservoir

No need to any moving hopper like translation or rotation of head parts to be able to fill the cylinder. Thanks to fixed cooling hopper and reservoir. Having moving parts at the head while taking the piston out of the cylinder for charging it, brings melt material come into contact with the head parts and making them dirty and it is difficult to clean.

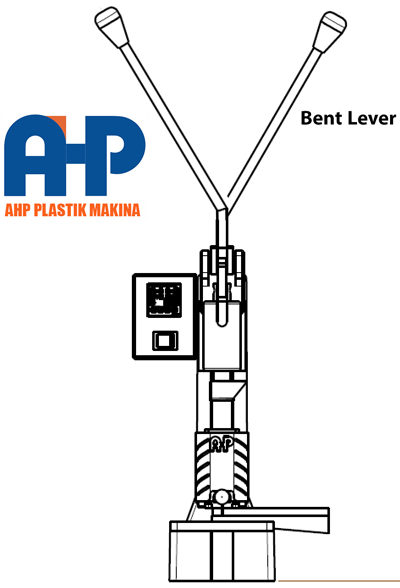

Bent Double Side Lever Handle

Bent lever makes it possible to have full view of the injection zone. Offset of force application compare to operator standing Infront of the machine make it easy to being the handle down for having maximum hand power during injection. Also it is proper for left hand operators to change the direction of the handle.

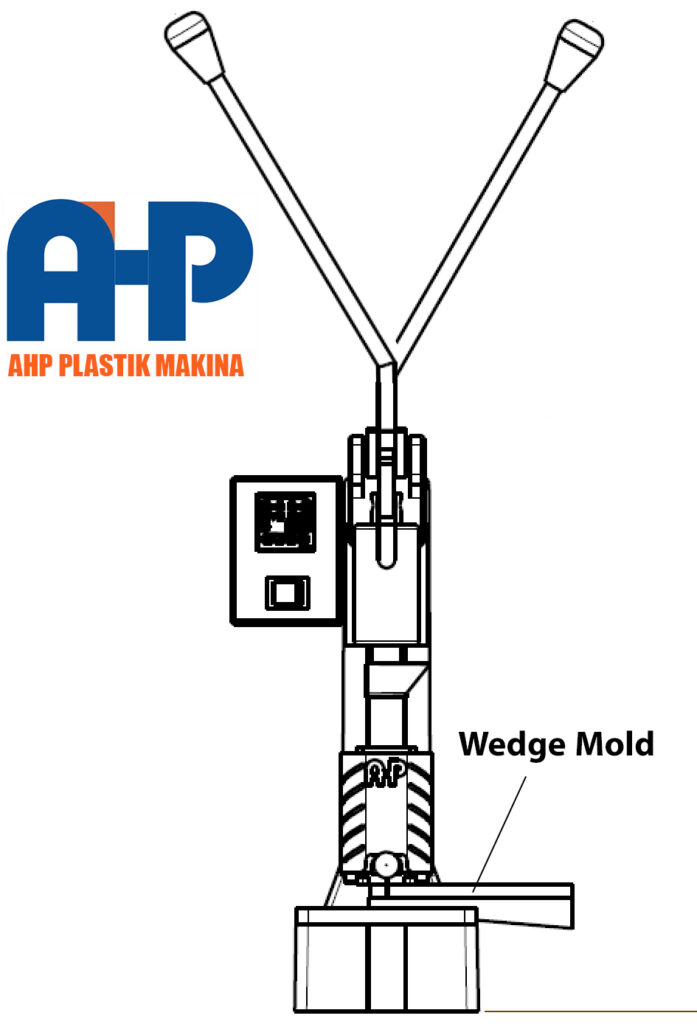

Wedged Mold

Having instant mold makes it possible to have surface contact of nozzle to the mold. Also we have possibility of placement of the mold under the nozzle from the side. Thanks to wedge application with optimum angle of wedge to have maximum contact between mold surface and nozzle.

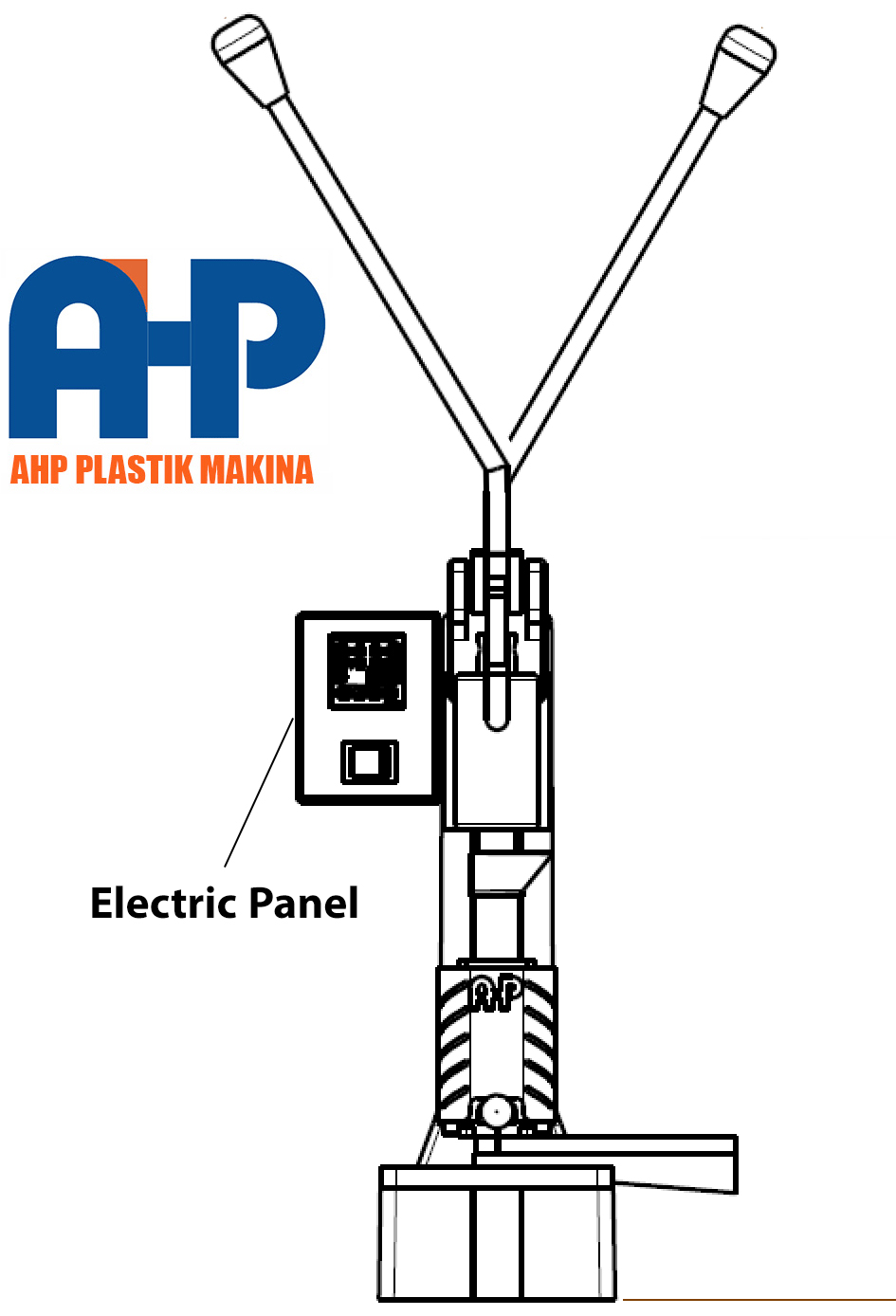

Electric Panel

Electric panel attached to the main structure, makes it more compact and easy for the operator to works with the panel.

Detachable Cylinder

Easy detachment of the cylinder from the front side (Compare to other brands that you don’t have access to cylinder even for cleaning, you can not detach the cylinder unless you disassemble whole machine body).

New design at AHP, makes it possible to inject different materials with different colors and flow characteristics. Easy to clean the cylinder. Easy to have multiple cylinders with one machine for multiple materials.

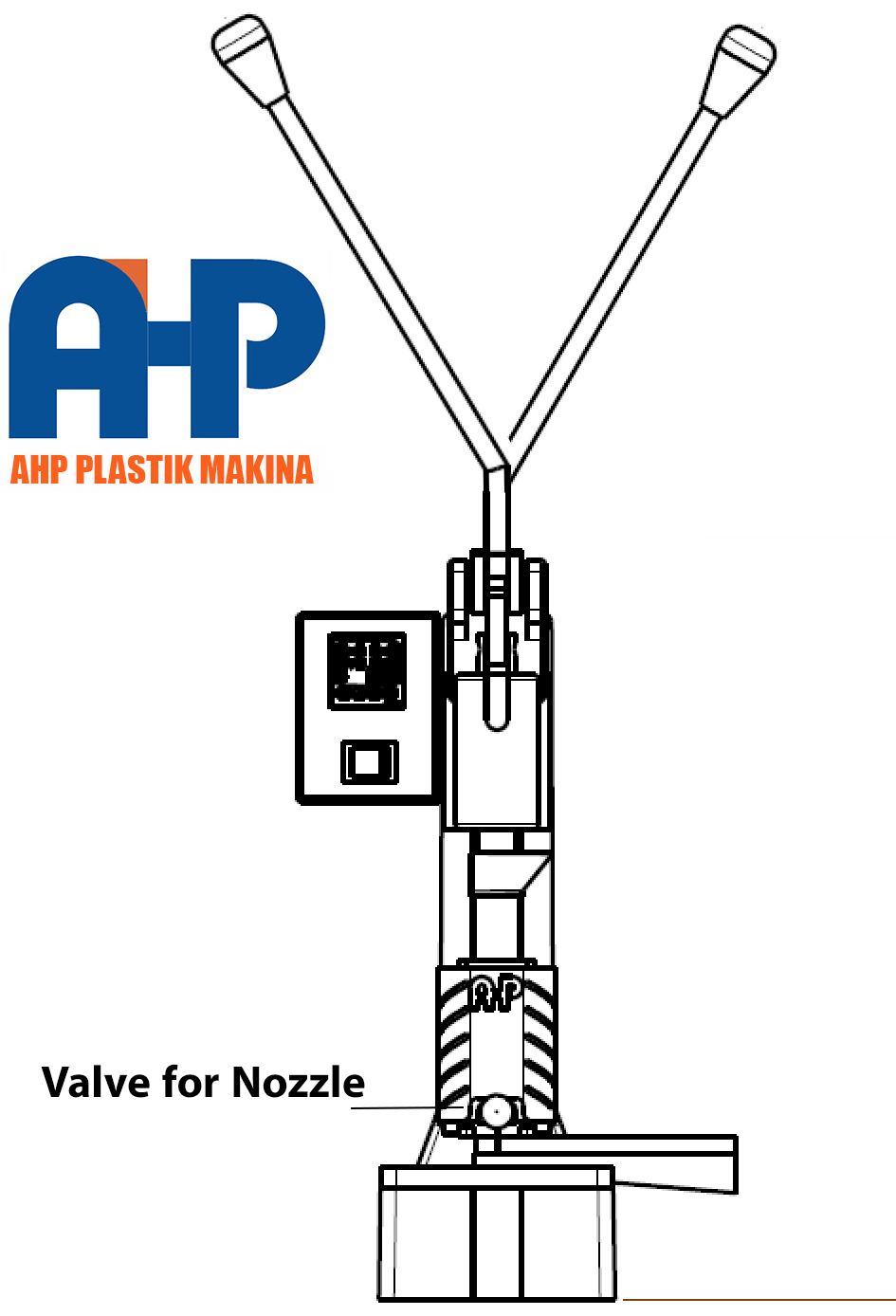

Nozzle Valve

Valve for nozzle makes it possible to compact material during melting. Compaction make the melt material free of air. This is crucial parameter specially for laboratory applications for making different test samples.

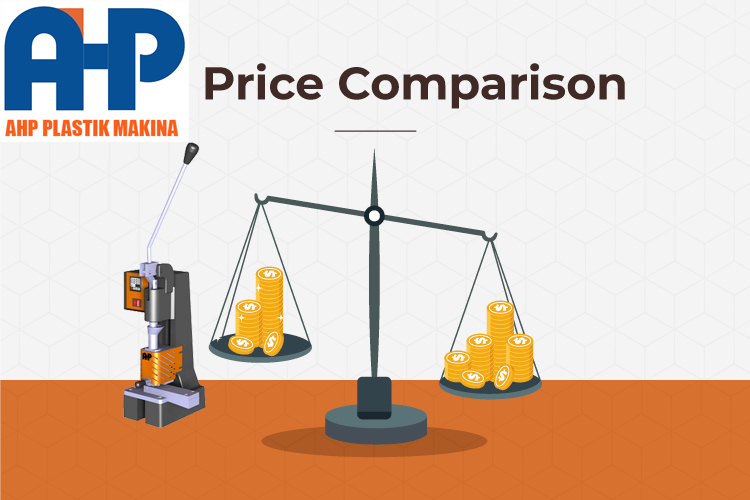

Price Comparison

Cast structure makes it possible to reduce the price of finished product compare to other brands. We reduced machined parts, time of machining and assembly time. That why you will pay less money for having manual injection molding machine.

Structure is Cast Iron

Check the dimensions of the cast iron structure to see the difference between our design and present models in the market. Beside robust structure, having no moving parts of the head during charging and injection makes it more easy, clean and comfortable for the operator. The stiffness of the cast structure is not comparable to the present models with the aluminum profiles, sheet metal works for the body and weak structures for the main column of the machine like using a metal pipes and rods.