Description

DURABILITY: Antioxidants (AO); HPOIT v OIT Test Methods for PE

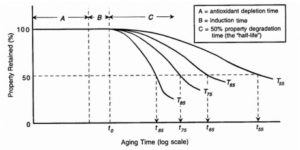

Figure 1: Stabilizers extend the “A” period for a specific polymer package resulting in longer half life (50%) at all temperatures of operation

History of Antioxidant Stabilizers and OIT Testing Methods

The OIT Test

To test the effectiveness of a stabilizer an accelerated ageing test method using heat was developed to compare different HDPE and LLDPE sheet products. The first ASTM test method for Oxidative Induction Time (OIT) was ASTM D 3895-14: Test Method for Oxidative- Induction Time of Polyolefins by Differential Scanning Calorimetry (DSC) (Figure 2). A small sample of the material to be tested is placed in the apparatus which measures heat and energy extremely accurately. The apparatus heats the sample to 200°C and at the appropriate time, oxygen is introduced into the system and the sample begins to oxidize.

Whilst oxidation is suppressed by the stabilizer, eventually the stabilizers are completely consumed, the material sample begins to combust, and additional energy is released. These events are timed, and the number of minutes between the introduction of oxygen and a change in the slope on the curve is recorded as this indicates the onset of combustion and, concurrently, that the entire stabilizer has been consumed. (Figure 3).

Early in the industry’s history, the only stabilization system available was a combination of hindered phenolic stabilizers (referred to as primary antioxidants) and phosphate compounds (referred to as secondary antioxidants). The ASTM 3895 method was quite functional for measuring the effectiveness of these original stabilizers in the various sheet materials on the market.

Development of Stabilizers and HP-OIT Test

In the 1990s, a new type of stabilizer became available: hindered amines (HALS or Hindered Amine Light Stabilizers). HALS was initially developed for the stabilization and protection of polyethylene clear/transparent films from degradation due to ultraviolet (UV) light and it was soon discovered that they also improved the performance and durability against oxidation as well. HALS began to be incorporated into the production of geosynthetics. Whilst HALS improved performance, as shown by field tests and other applications, the existing laboratory test ASTM 3865 reported a poor OIT value. HALS and the by-products that HALS produce whilst performing their stabilization function had a tendency to evaporate and volatilize during OIT testing which is conducted at an elevated temperature of 200°C. In addition, there was a very poor correlation between the OIT (ASTM 3895) results, the level of HALS present in the sheet, and the actual performance of the materials.

The HALS stabilizers required a new test method; one that operated at lower temperature. By increasing the pressure to 3.4MPa and reducing the temperature (1,50o) within the test vessel, a similarly aggressive environment was created (Gay Lussac’s Law P1T1 = P2T2 where T is in Kelvin). This resulted in the ASTM D 5885 – 06 (2012) Test Method for Oxidative Induction Time of Polyolefin Geosynthetics by High-Pressure Differential Scanning Calorimetry (HP-DSC) or HPOIT (Figure 4).

Choice of OIT Methods

The two test methods continue to exist and the Geosynthetic Institute has addressed this by allowing a geomembrane to be tested using either ASTM D 3895 or ASTM D 5885. This is referenced by the Institute in a white paper (GSI White Paper #32 “Rationale and Background for the GRI-GM13 Specification for HDPE Geomembranes”).

“Oxidative induction time (OIT) – Both the standard (Std-OIT, ASTM D 3895) and high pressure (HP- OIT, ASTM D 5885) tests are included in the specification. The purpose of including two OIT tests is to provide an option for manufacturers to choose the appropriate test to evaluate their specific antioxidant package. If some of the antioxidant packages have an evaporation temperature lower than 200°C, the Std-OIT test is not the suitable method. For those antioxidant packages, the HP-OIT test is the proper method (Hsuan and Guan, 1997).”

Specifications

Increased pressure influences all physical changes and chemical reactions in which a change in volume occurs. Study of thermal effects under pressure – increase the reaction rate or shift evaporation to higher temperature. High pressure differential scanning calorimetry allows you to measure samples under precisely defined atmospheres at pressures of up to 3.4 MPa as a function of temperature or time. Higher pressures and temperatures accelerate chemical reactions and shorten analysis times. Increased pressure is a factor that influences all physical changes and chemical reactions in which a change in volume occurs. For material testing, process development or quality control there is often no alternative to DSC measurements under pressure. Increased pressure suppresses vaporization and shifts the effect to higher temperatures. The high pressure differential scanning calorimetry (HPDSC) is an excellent instrument for studying the influence of pressure and atmosphere on a sample or for separating an effect that is overlapped by vaporization.

- As per ASTM D 5885

- Suitable for testing of geomembranes, geotextiles

- Simulates real process condition of materials

- Reduce of analysis time comparing normal DSC

- Pressure range up to 3.5 MPa

- High pressure causes higher gas concentration during testing

- Accuracy +-0.2K

- Reproducibility +-0.1K

- Heating rate up to 50K/min

- SS304 pressure vessel

- Including standard Tin, Ind pellets for calibration checkout

- 200pcs of aluminum pans

- RS485-usb converter

- Heating rate up to 50 C/min

- Automatic cycle control

- Automatic gas valves

- Making report templates as operator settings

- Data output for universal analyzer software like TA

- High sensitivity

- Calibration software

- Calculation of Onset points-Max-Min points-Slope analysis-…

- Graph analysis

- Data processing

- DSC-Temp-Time data saving

- Software CD

- User manual

- Capable of measuring OIT-DSC

- Temperature accuracy 0.1C

- Usable for OIT measurement and melting point

- N2 and O2 pressure regulator

- Power 220V-50Hz

- Training video