The invention provides apparatus and a method for forming a bend in a linear section of thermoplastic pipe. The apparatus comprises an anvil having a concave working surface which defines an arc of at least the bend angle of the bend to be formed in the pipe section and which is transversely arced at a radius essentially the same as the radius of the pipe, the anvil further including a collar for retaining an end of the pipe section adjacent the working surface. The method of the invention comprises the steps of heating the pipe section to the softening temperature thereof, driving a flexible mandrel of substantially the same internal diameter as the pipe and of at least the same length as the pipe section into the pipe section, loading the pipe section and mandrel onto an anvil having a concave working surface which defines an arc of at least the bend angle of the bend to be formed in the pipe section and which is transversely arced at a radius essentially the same as the radius of the pipe, the anvil further including a collar for retaining an end of the pipe section adjacent the working surface, drawing the end of the pipe section opposite the retained end towards the working surface to bring the bulk of the pipe section into contact with the working surface, allowing the pipe section to cool to below the softening temperature while held in contact with the working surface and withdrawing the mandrel from the pipe section.

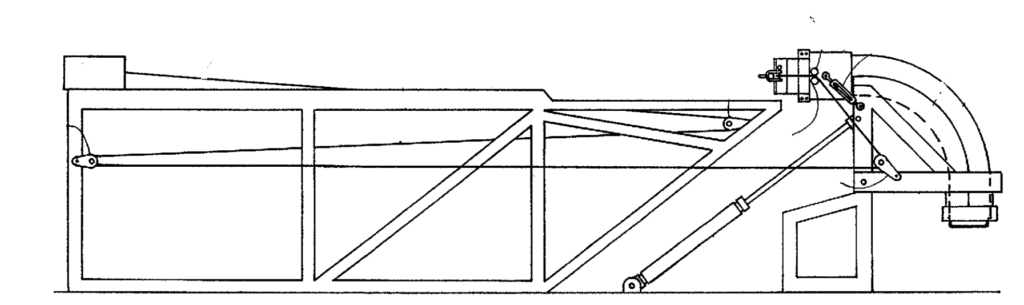

Sweep Bend Manufacturing Stand

- Suitable for making HDPE sweep bend OD and Thickness as per customer request

- Including stepped bed structure with trolley

- Winch for sample movement

- Hydraulic system for bending

- Suitable for making 30o, 45o , 60o , 90o

- Chamber for immersion heating of samples for about 60 min

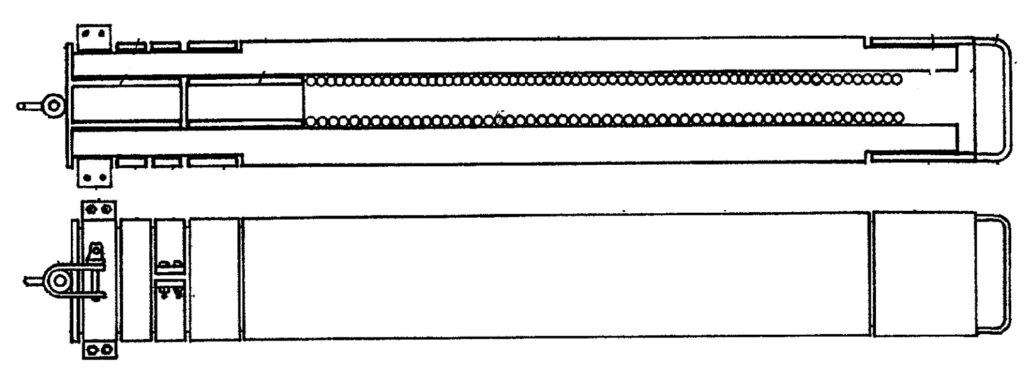

- Internal flexible mandrel for pipe including helical spring inside

- Collar for pipe sizes as per request

- Adjustable table step height for different thickness of fittings (Internal mandrel need to be order separately)

- Anvil according to requested pipe size

- Center radius of anvil is 3 times the diameter of pipe

- Cooling sample by air blow

- Chamber internal size of 120*140*180cm (for sizes up to 250mm)

- Heating chamber power is 12 KW-3Ph (for up to 250mm)

- Pneumatic door for heating chamber

- Circulation system for heating chamber for temperature uniformity

- Digital controller for heating chamber