Plastics — Determination of the tendency of compounds and products based on vinyl chloride homopolymers and copolymers to evolve hydrogen chloride and any other acidic products at elevated temperatures

3 Principle

A test portion of the PVC compound or product is maintained at an agreed temperature in still air until the color of a Congo red paper held above it changes from red to blue. If universal indicator paper is used, the relevant color change is that corresponding to pH 3. The time required for the color change is taken to be the stability time, ts.

4 Reagents

4.1 Congo red indicator paper.

Commercial Congo red paper is suitable, providing that it is available in 10 mm width. The paper may also be prepared by immersing strips of filter paper, 10 mm wide, in a 0,15 % (m/m) solution of Congo red in methanol, and drying.

4.2 Universal indicator paper, in roll form, with a pH range of 1 to 10, shall be used. The paper shall be provided with a colour scale in order to interpret the changes in pH.

5 Apparatus

5.1 Test tubes, with the following dimensions:

external diameter: approximately 17 mm

wall thickness: approximately 0,4 mm

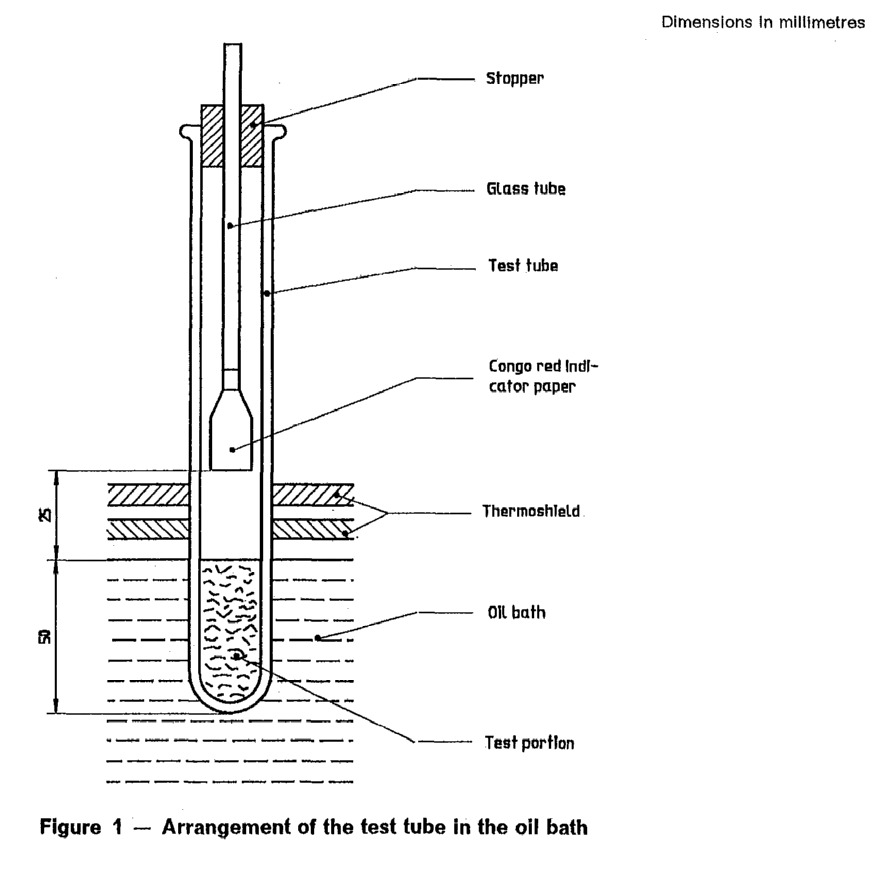

Stoppers are required with holes through the cen tres which provide an interference fit for the glass

tubes (5.2). The complete arrangement is shown in figure 1.

5.2 Small glass tubes, 2 mm to 3- mm in internal diameter and approximately 100 mm long (see figure 1).

5.3 Oil bath, with a capacity of at least 10 litres. The bath shall be capable of operating in the temperature range 170 °C to 210 °C and of maintaining the test temperature with an accuracy of ± 0,5 °C throughout the working volume.

5.4 Heat-resistant insulating shield, drilled to permit the insertion of test tubes (5.1) and positioned to permit the suspension of the tubes in the hot oil bath (5.3) to a depth of approximately 50 mm.

5.5 Thermometer, provided with a scale convenient for reading the oil bath temperature in the range 170 °C to 210 °C and with a scale division of 0,1 °C.

5.6 Stopclocks, two or four stopclocks are required, depending on the parameters to be measured (see 9.6).

6 Preparation of test portions

The measured stability times depend to some extent on the surface area of the prepared test portions as well as on their thermal history. Any cutting or grinding of a material necessary to produce the test portions shall be carried out in a uniform manner. Heating of the material during grinding shall be avoided.

6.1 PVC plastisols

Spread these materials on glass plates and gel in an oven at an agreed temperature so that sheets 0,5 mm thick are formed. Cut these sheets into squares with sides approximately 2 mm long.

6.2 PVC pellets, extrudates, mouldings, thick sheet, etc.

Cut or grind these materials so that more than 80 % of the material passes through a 2,0 mm sieve (ISO 565, R 2013 series) and an adequate amount is retained on a 1,4 mm sieve to prepare the test portions.

8.3 PVC film and sheet

Cut these materials into squares or cubes with sides no longer than 2 mm.

6.4 PVC coatings

Separate these materials from the substrate and then treat as in 6.2 or 6.3.

6.5 Insulation or sheathing of cables and conductors

Cut thin slivers with the dimensions indicated in 6.2.

7 Number of tests

For each sample, conduct at least two determinations, using two separate test tubes that are immersed in the oil bath at the same time.

8 Temperatures for dehydrochlorination

These are preferably:

200 °C for unplasticized compounds and products;

200 °C for compounds and products for cable insulation and sheathing;

180 °C for other plasticized compounds and products.

9 Procedure

9.1 Place a quantity of the PVC material to be tested, prepared in accordance with the appropriate part of clause 6, in a test tube (5.1) such that the tube is filled to a depth of about 50 mm. Fill a second test tube (5.1) in the same way. Shake each tube gently, taking care that the pieces do not form a compact mass or adhere to the walls of the test tube.

9.2 Preheat the oil bath (5.3) to near the agreed test temperature, and adjust to the exact test temperature as indicated by the thermometer (5.5).

9.3 For each test tube, cut out or select a strip of the chosen indicator paper (4.1 or 4.2) 30 mm long and 10 mm wide. Roll or fold one end of the indicator paper strip and insert it into the glass tube (5.2). Wet the indicator strip with grade 2 water as defined in ISO 3696. Insert the glass tube into the stopper. Slide the glass tube into the test tube, close the test tube with the stopper and adjust the position of the glass tube in the stopper so that the lower edge of the paper is located 25 mm above the top of the test portion.

9.4 Immerse each test tube in the oil bath to the level of the upper surface of the test sample, starting a stopclock (5.6) for each test tube.

9.5 Stop the stopclock for each of the test determinations when there is the first clear sign of a change from red to blue in the Congo red indicator paper. When using universal indicator paper, the end point shall correspond to the colour indicating pH 3.

9.6 When certain stabilizers are used in the PVC composition, the coiour change is slow and not very distinct. in this case, when using Congo red indi cator paper, record two different times, correspond ing to the first sign of colour change from red to violet and then the permanent change from violet to blue.

Four stopclocks are required to conduct the test in these circumstances.

10 Expression of results

Record the time(s), in minutes, for each of the two determinations. The arithmetic mean of these values is the stability time ts.

When two values differ by more than ±10 % from the mean, the results shall be discarded and the test repeated.

Congored Tester According to ISO 182-1

- 4 stations for sample placement

- Including congo red paper

- Digital PID temperature controller

- A digital timer is included

- Oil tank with stirrer