6 Test methods

6.1 Preparation of test specimens

6.1.1 Temperature

Prepare all test specimens at (23 ± 2) C.

6.1.2 Amalgamation

The mass of the amalgam mix shall be sufficient to make a test cylinder (8 ± 1) mm high after condensation with a diameter according to figure 1. If necessary, adjust the height of the cylinder by condensing only a Portion of the amalgam mix into the mould. For alloy supplied as tablets or powder, the alloy mass and the mercury mass to be mixed, the capsule (if needed), the pestle (if needed), and any other mixing accessories required shall conform to those recommended by the manufacturer in accordance with 7.3.1 and 7.3.2. For capsulated alloy and mercury, simultaneously amalgamate as many capsules as needed. An amalgamator that camplies with ISO 7488 shall be used. The amalgamator’s frequency (or machine setting) and the amalgamation time shall be as specified by the manufacturer in accordance with 7.3.2.

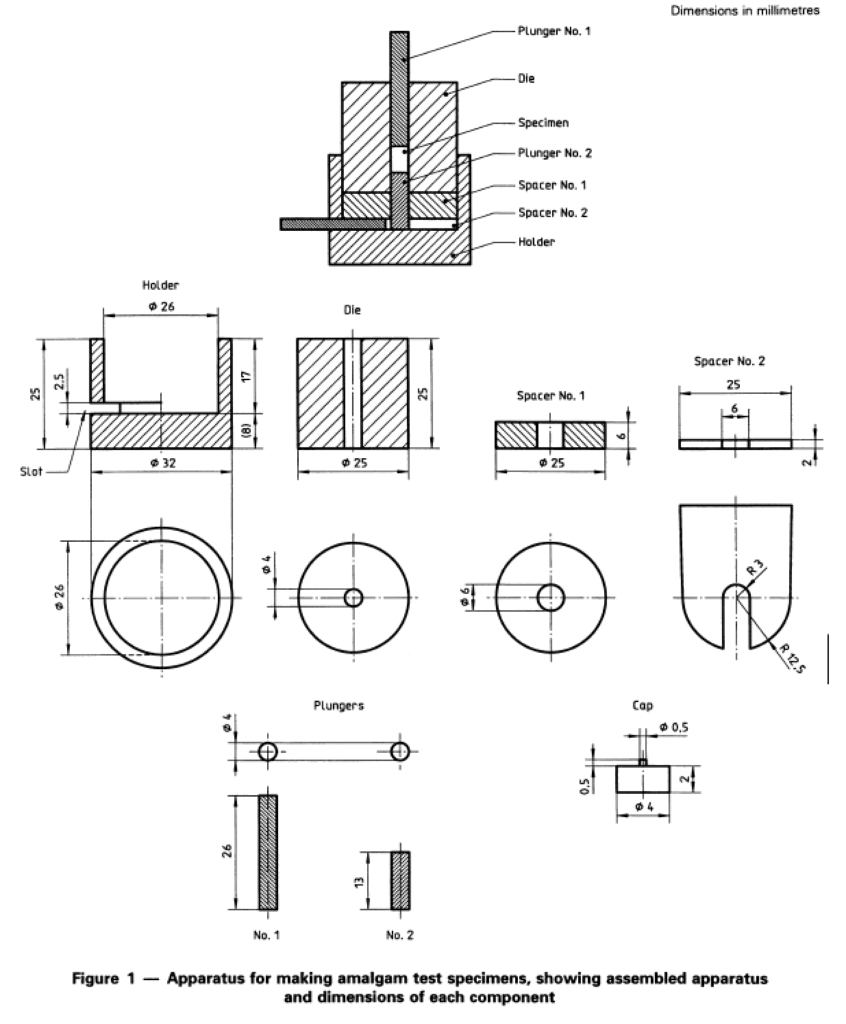

6.1.3 Apparatus for preparation of test specimens for determination of creep, dimensional Change and compressive strength

Use an all-mechanical apparatus as shown in figure 1. The holder, spacers and cap need not be hardened; they shall be made of cold-rolled or stainless steel. Make the die and plungers of hardened tool steel or hardened stainless steel. Hone the working surfaces of the die and plungers to a surface roughness value (ra) of not greater than 6.3 ra when tested in accordance with ISO 468. Limits of clearance between the die and plungers shall be F7/h7 in accordance with ISO 286-2.

Assemble the holder, spacers Nos. 1 and 2, the die and plunger No. 2 as shown in figure 1. Position the cap shown in figure 1 on top of plunger No. 2 when dimensional Change specimens are being made. A glass plate may be used instead of a cap.

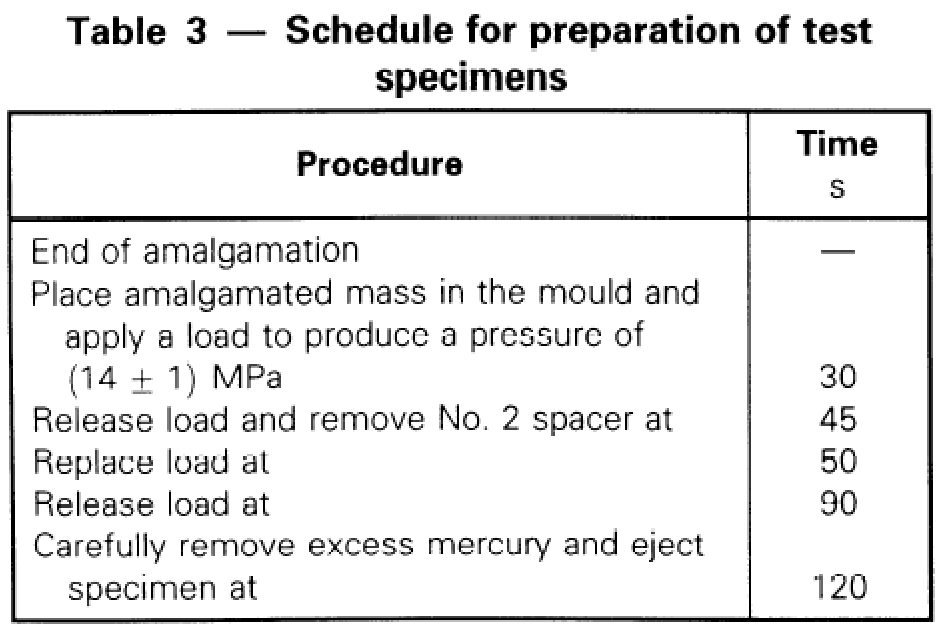

6.1.4 Condensation

Empty the coherent mass of amalgamated material on top of the cavity of the die and immediately insert the amalgam into the mould with several thrusts of an amalgam condenser slightly less than 4 mm in diameter. Do not express mercury during insertion. When preparing specimens for dimensional Change tests, insert the other cap (shown in figure 1) with the flat surface up. Insert plunger No. 1 and follow the time schedule in table3. The specimen shall not be trimmed. After ejection, transfer the specimen to an environment maintained at (37 ± 1) C.

6.2 Determination of creep

6.2.1 Preparation of test specimens

Take three specimens prepared in accordance with 6.1), using plungers Nos. 1 and 2 (sec figure 1). Store the specimens at (37 ± 1) C for 7 days. Prior to testing, prepare the surface of both ends of each specimen plane and perpendicular to the axis with wet ASTM 600 grit size or FEPA Pl 200 Silicon carbide Papers. Measure the length of each specimen and record it to the nearest 10 Micrometer as the original length.

6.2.2 Procedure

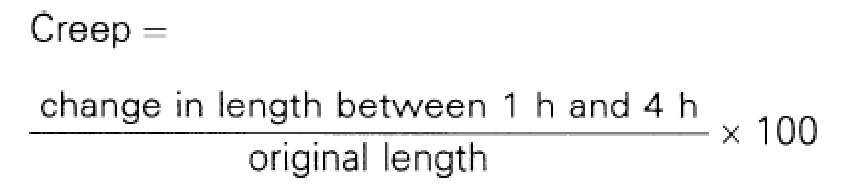

Axially apply a stress of (36 ± 0,2) MPa continuously to the specimen for 4 h at (37 ± 0,5) C. Record the Change in length between the 1 h and 4 h readings and calculate the creep to the nearest 0,1 %, as follows:

If one out of three fails, make two more. Three out of three or four out of five shall meet the requirement given in table2.

Creep Tester for Amalgam According to ISO 1559

- Force application mechanism is lever mechanism

- Pressure value is 36 MPa

- European sensors for displacement measurement

- Includes 3 stations for measurement

- Software is included

- Windows-Based software

- Report in MS-WORD

- USB connection to computer

- Temperature control cabin

- Sample cabin elevator

- Temperature and displacement monitoring in software

- Graphing of all data

- Circulation system for temperature homogeneity

- PID temperature control of sample chamber at (37 ± 1) C

- Sample preparation devices are not included (customer need to get ask for price in case of need)