5 Apparatus

5.1 Testing machine.

The testing machine shall be of class 1 or class 0 in accordance with ISO 7500-1 and shall be capable of the following:

⎯ a constant rate of displacement of (50 ± 5) mm/min;

⎯ recording force and displacement;

⎯ providing an autographic read-out of force and displacement.

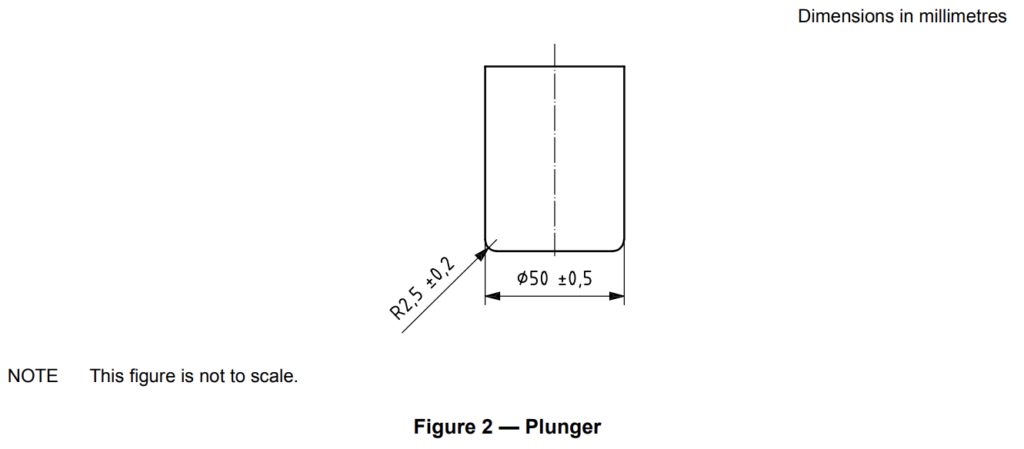

5.2 Plunger.

A stainless steel plunger with a diameter of (50 ± 0,5) mm is used. The radius of the leading edge of the plunger shall be (2,5 ± 0,2) mm (see Figure 2).

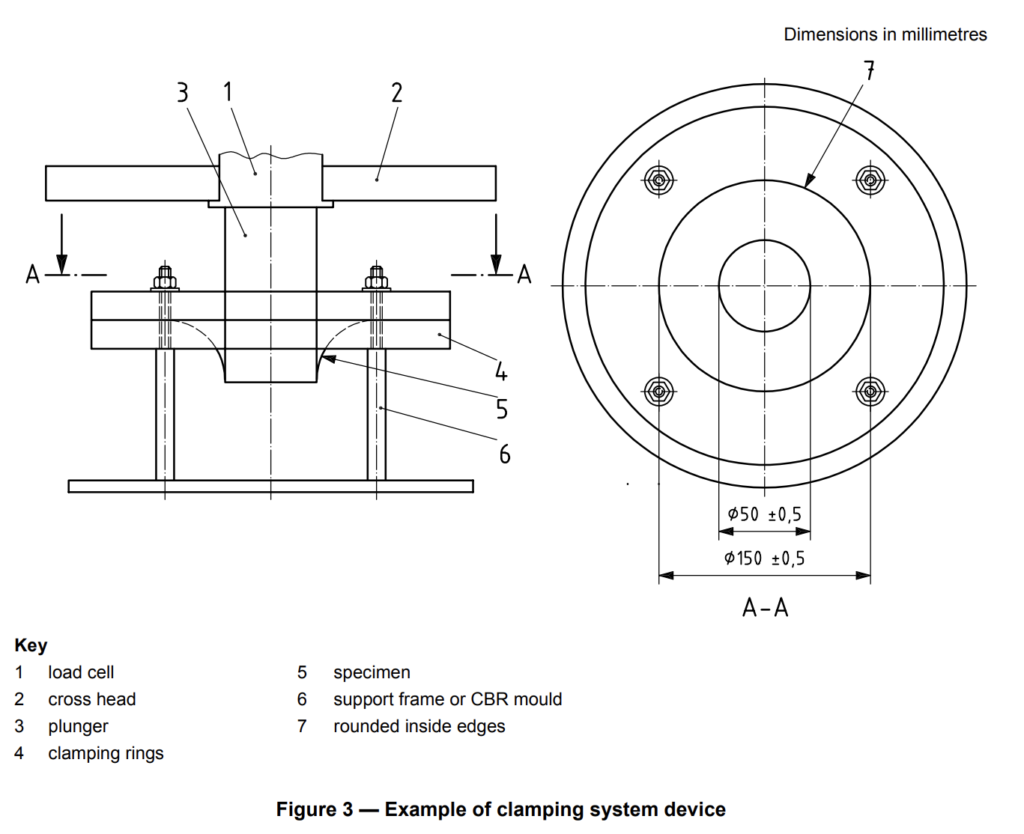

5.3 Clamping system.

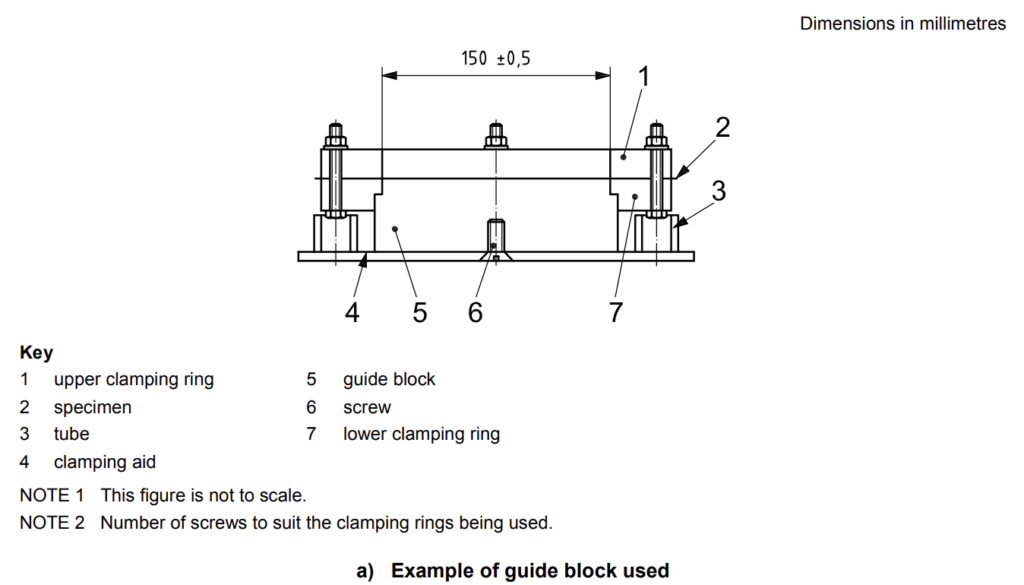

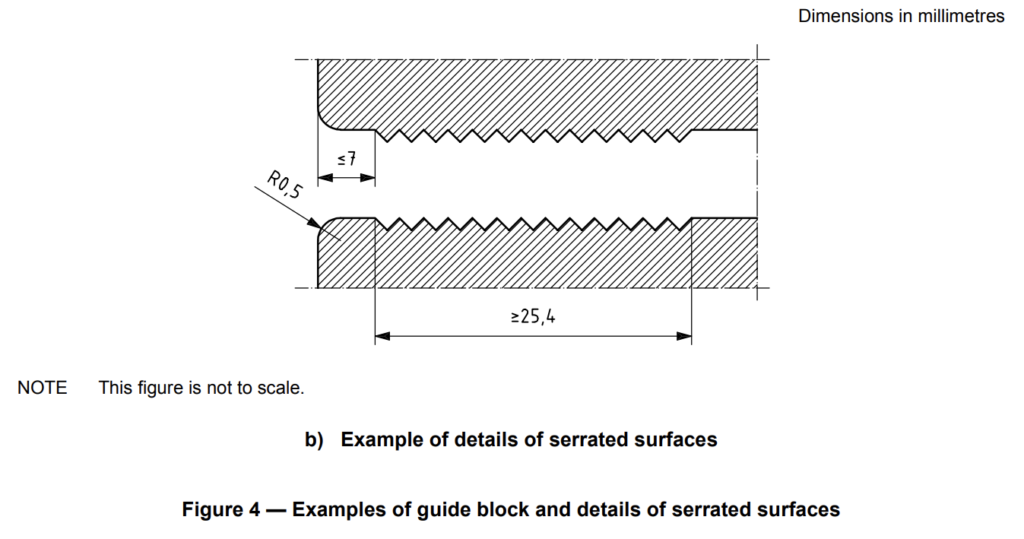

The clamping system shall prevent slippage or cutting of the specimens. The internal diameter of the clamping rings shall be (150 ± 0,5) mm. Examples of a clamping system and a guide block are shown in Figure 3 and Figure 4. The surfaces should be arranged so that the distance between the inner diameter of the ring and the gripping zone (i.e. start of serration, corrugations, etc.) does not exceed 7 mm.

8 Procedure

Secure a specimen between the clamping rings of the clamping system (see Figure 3), e.g. by using a guide block [see Figure 4 a)]. Place the specimen and clamping system in the testing machine.

Advance the plunger (see Figure 2) onto and through the specimen at a rate of (50 ± 5) mm/min and start recording the displacement at preload of 20 N.

Repeat the procedure on the remaining specimens.

Static Puncture Test (CBR test) according to ISO 12236

- Max load 50KN

- Body steel

- Both ends are male adapters

- According to ISO 12236