4 Apparatus, materials and reagents

4.1 Suitable mechanical device, consisting of a water bath containing a rotatable shaft which supports,

radially, stainless steel containers with a diameter of (75 ± 5) mm and a height of (125 ± 10) mm, of capacity (550 ± 50) ml, the bottom of the containers being (45 ± 10) mm from the centre of the shaft.

The shaft/container assembly is rotated at a frequency of (40 ± 2) min−1. The temperature of the water bath is thermostatically controlled to maintain the test solution at the prescribed temperature ±2 °C.

Other mechanical devices may be used for this test, provided that the results are identical to those obtained using the apparatus described.

4.2 Non-corrodible (stainless) steel balls, ≈ 6 mm in diameter.

4.3 Adjacent fabrics (see ISO 105-A01). Use either 4.3.1 or 4.3.2.

NOTE Supplies of spun acetate may be limited due to decreased manufacturing.

4.3.1 A multifibre adjacent fabric, complying with ISO 105-F10, appropriate to the temperature used:

⎯ a multifibre adjacent fabric [DW1)] containing wool and acetate (tests at 40 °C and 50 °C and in certain

cases, to be indicated in the test report, also at 60 °C);

⎯ a multifibre adjacent fabric [TV2)] not containing wool and acetate (in certain tests at 60 °C, and in all tests at 70 °C and 95 °C). Consideration should be made in the use of multifibre with wool as the combination of temperature and sodium perborate at 60 °C might be harmful to the wool.

4.3.2 Two single-fibre adjacent fabrics, complying with the relevant ISO 105-F01 to F07 standards. One

of the adjacent fabrics shall be made of the same kind of fibre as that of the textile to be tested, or that

predominating in the case of blends, and the second piece made of the fibre as indicated in Table 1 or, in the case of blends, of the kind of fibre second in order of predominance, or as otherwise specified.

4.3.3 If required, a non-dyeable fabric (e.g. polypropylene).

4.4 Detergent, without optical brightener (WOB).

4.4.1 Detergent solution.

A minimum volume of 1 litre of detergent solution shall be prepared, because of possible lack of homogeneity of the detergent powder.

Either of the detergents in 4.4.2 or 4.4.3 may be used.

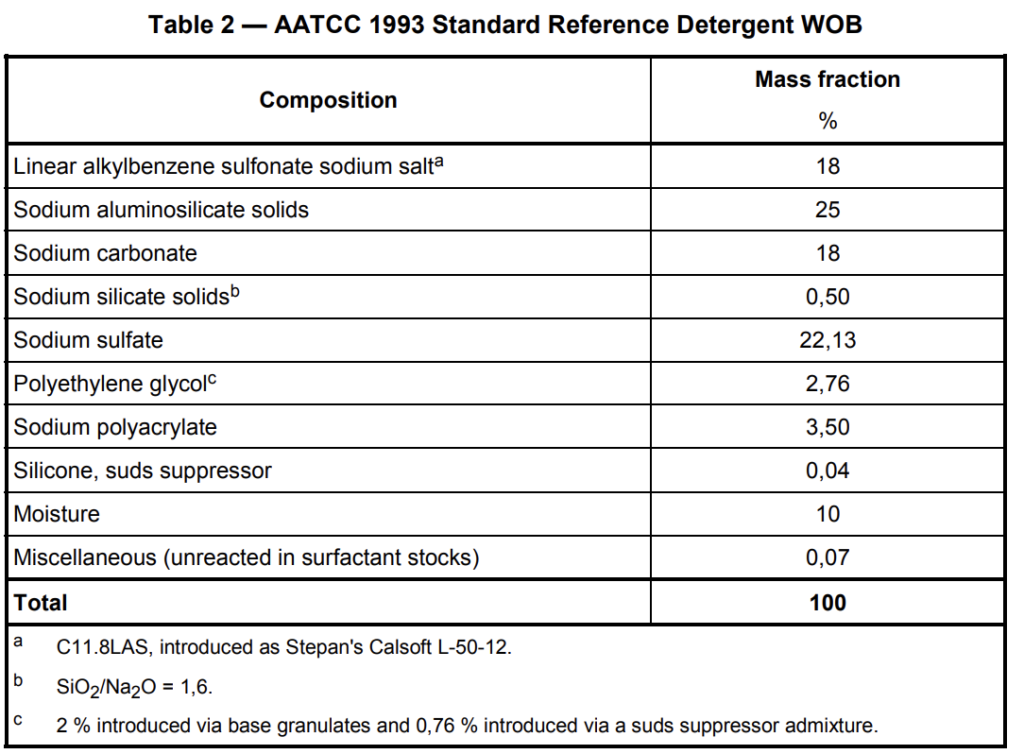

4.4.2 AATCC3) 1993 Standard Reference Detergent WOB.

The detergent is low-sudsing; the surfactants composing the detergent are anionic, with a small proportion of non-ionic, and are biodegradable. Properties and composition are given in Table 2.

4.4.3 ECE4) Detergent with Phosphates.

In countries where perborates are used in laundering, the ECE Reference Detergent for colour fastness

testing, without optical brightener, may be used. The nominal composition of the ECE Detergent with

Phosphates is given in Table 3.

NOTE Information on the availability of this detergent can be obtained from national standards organizations.

4.5 If required, sodium carbonate (Na2CO3).

4.6 Sodium hypochlorite solution or lithium hypochlorite solution.

The pH value and available chlorine content of a large number of trade-named solutions of sodium

hypochlorite (NaOCl) vary from pH 9,8 to pH 12,8 and the Cl2 content from 40 g/l to 160 g/l. The actual

available chlorine shall be determined before use and the following method is suggested.

Pipette a 1,00 ml portion of the stock sodium hypochlorite solution into a conical flask and dilute to 100 ml with grade 3 water (4.8). Add 20 ml of 294 g/l sulfuric acid (H2SO4) solution and 6 ml of 120 g/l potassium iodide (Kl) solution. Titrate with standard volumetric sodium thiosulfate solution, c(Na2S2O3·5H2O) = 0,1 mol/l. The available chlorine (Cl2) content is given, as a percentage by mass, by the formula:

4.7 If required, sodium perborate tetrahydrate (NaBO3·4H2O).

4.8 Grade 3 water, complying with ISO 3696.

4.9 Grey scale for assessing change in colour, complying with ISO 105-A02.

4.10 Grey scale for assessing staining, complying with ISO 105-A03.

4.11 Spectrophotometer or colorimeter for assessing change in colour and staining, complying with

ISO 105-A04 and ISO 105-A05.

4.12 If required for souring treatment, acetic acid solution containing 0,2 g of glacial acetic acid per litre.

5 Test specimen

5.1 If the textile to be tested is fabric, either

a) attach a specimen measuring (100 ± 2) mm × (40 ± 2) mm to a piece of the multifibre adjacent fabric

(4.3.1), also measuring (100 ± 2) mm × (40 ± 2) mm, by sewing along one of the shorter edges, with the

multifibre adjacent fabric next to the face side of the specimen, or

b) attach a specimen measuring (100 ± 2) mm × (40 ± 2) mm between the two single-fibre adjacent fabrics (4.3.2) by sewing along one of the shorter edges.

5.2 Yarn may be knitted into fabric and tested in this form. Where yarns or loose fibres are to be tested,

take a mass of the yarn or loose fibre approximately equal to one-half of the combined mass of the adjacent fabrics and either a) place it between a (100 ± 2) mm × (40 ± 2) mm piece of the multifibre fabric (4.3.1) and a (100 ± 2) mm × (40 ± 2) mm piece of the non-dyeable fabric (4.3.3), and sew them along all four sides (see ISO 105-A01), or

b) place it between (100 ± 2) mm × (40 ± 2) mm pieces of the two specified single-fibre fabrics (4.3.2) and

sew them along all four sides.

6 Test procedures

6.1 Prepare the wash liquor by dissolving 4 g of detergent per litre of water (4.8). For all C, D or E tests,

adjust the pH as stated in Table 4 by adding approximately 1 g of sodium carbonate per litre of solution. The liquor should be cooled to 20 °C before the pH is measured. For the A and B tests, no adjustment of pH is required.

6.2 For tests where perborate (4.7) is employed, prepare the washing solution containing perborate at the

time of use by heating the liquor to a maximum temperature of 60 °C for not more than 30 min.

6.3 For tests D3S and D3M, add to the wash liquor sufficient sodium hypochlorite solution (4.6) or lithium

hypochlorite solution (4.6) to provide the concentration of available chlorine specified in Table 4.

6.4 Add to each stainless steel container (4.1) the volume of wash liquor specified in Table 4. Except for

tests D2S and E2S, adjust the temperature of the liquor to within ±2 °C of the specified temperature and then place the specimen, together with the specified number of steel balls (4.2), in the container. Close the container and operate the machine at the temperature and for the time specified in Table 4.

6.5 For tests D2S and E2S, place the specimen in the container at a temperature of approximately 60 °C,

close the container and raise the temperature to within ±2 °C of the specified temperature in not more than 10 min. Begin timing the test as soon as the container is closed. Operate the machine at the temperature and for the time specified in Table 4.

6.6 For all tests, remove the composite specimen at the end of the wash and rinse twice for 1 min in two

separate 100 ml portions of water (4.8) at 40 °C.

6.7 In countries where the practice is to sour at the end of the washing operation, the following optional

operation may be conducted.

Treat each composite specimen in a 100 ml portion of acetic acid reagent (4.12) for 1 min at 30 °C. Then,

rinse each composite specimen in a 100 ml portion of water (4.8) for 1 min at 30 °C.

6.8 For all methods, extract the excess water from the composite specimen.

6.9 For all methods, dry the specimen by hanging it in air at a temperature not exceeding 60 °C, with the

parts in contact only at the line of stitching.

6.10 Assess the change in colour of the specimen and the staining of the adjacent fabric using the grey

scales (4.9 and 4.10) or instrumentally (see ISO 105-A04 and ISO 105-A05).

6.11 If testing is performed at temperatures other than those listed in the method, it must first be agreed

upon between the interested parties and detailed in the report [7 j)].

Colour Fastness Tester According to ISO 105-C06

- Power 12 KW

- Including 8 pots

- PID temperature control

- Including digital timer

- SS304 chamber

- Shaft rotation speed 40rpm

- 8 pots of 550ml capacity

- Chemicals and sample preparation devices is not included