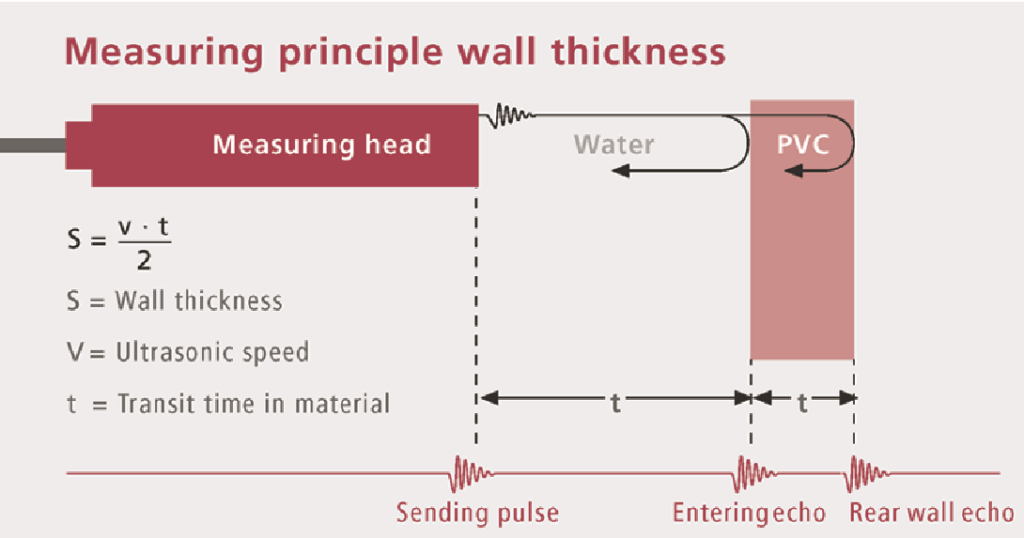

Ultrasonic technology for thickness measurement is using ultrasound reflection time between our surface of the pipe and inner surface. If you calibrate the device for sound speed in the target material then machine can calculate the thickness.

Sound speed in different materials depends mainly on material type and temperature. Of course when you calibrate device for specific situation, it is applicable for that situation. Suppose that vacuum tank temperature during extrusion if 16C and you calibrated machine for this working situation this is not applicable for the tank temperature of 30C. because sound speed in different temperatures are different for PE material. This is main weak point of ultrasonic technology specially for high thickness pipes. If you have very stable extrusion line with capabilities of good chillers for making stable water temperature and also there is soft water supply in production line , Yes go ahead and purchase the machine.

It will also help you for centering the dies during extrusion process.

Comparing to immersion method, m-Line technology can be used even for big sizes of pipes with very economic prices. because you don’t need very big SS304 tank that will also need high price for maintenance of the system.

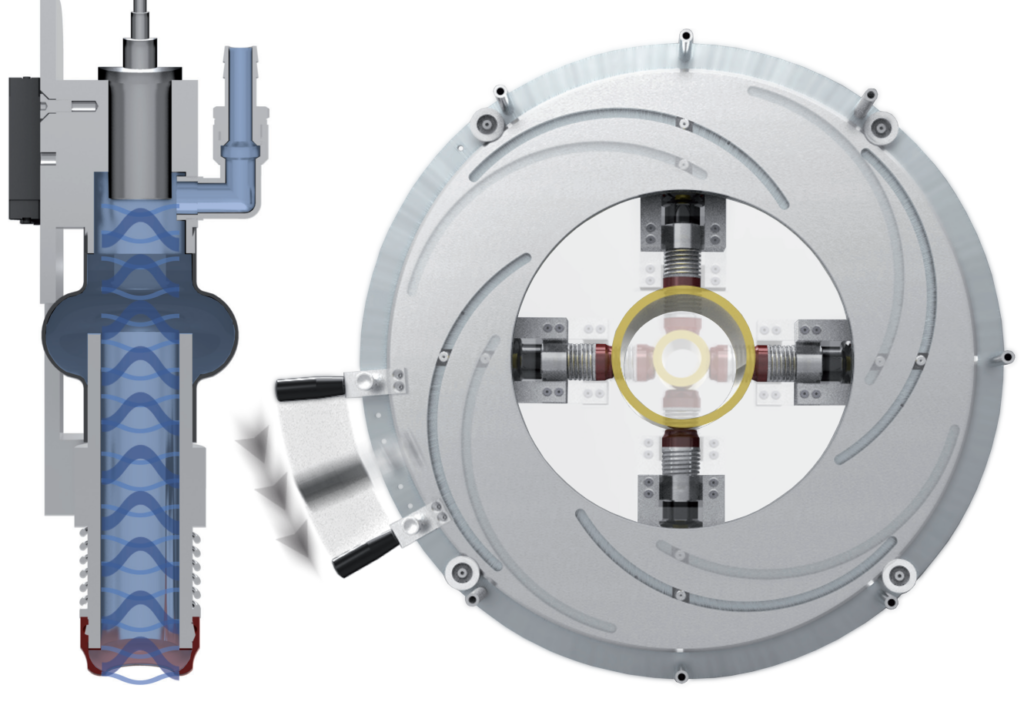

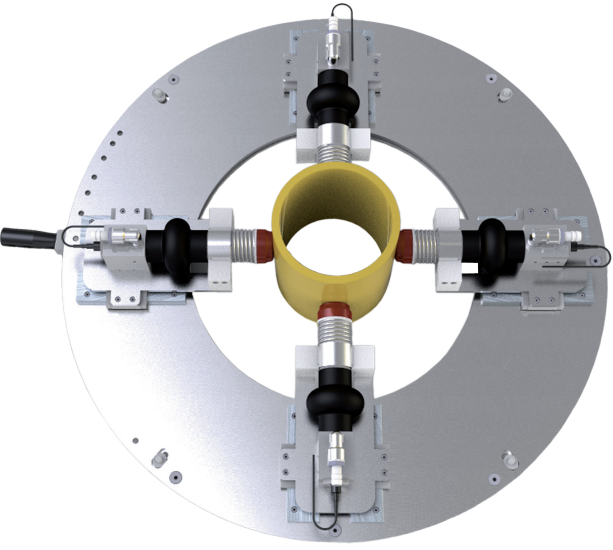

This m-Line system uses 4 sensor around the pipe and each sensor will come up for measurement every 2 seconds. Means you have a light on the panel showing which sensor thickness value is on the screen. right, left, top and bottom. This interval time can be adjusted up to 16 seconds.

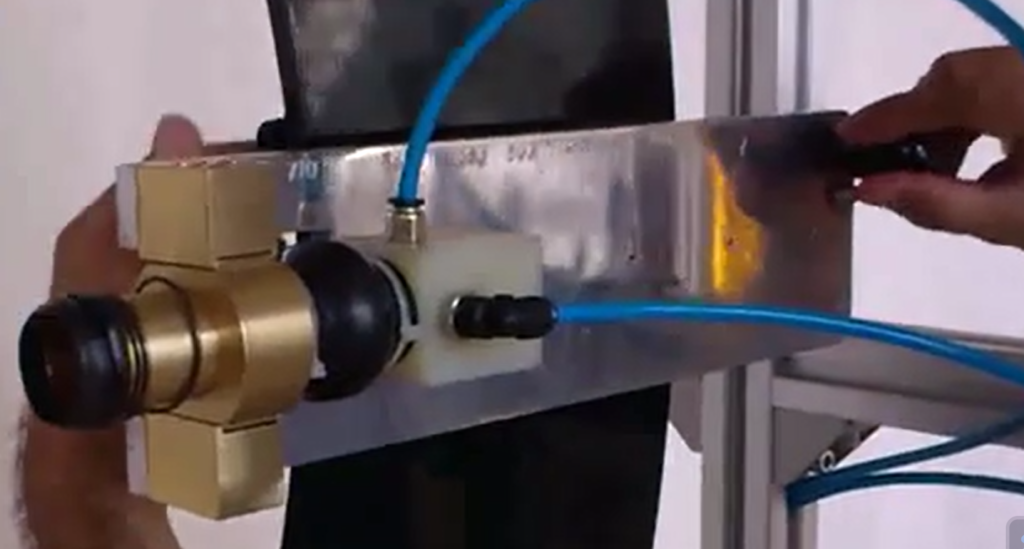

We have two type of this m-Line system, first one is for smaller sizes that bring sensors inward and outward only by handle. by rotary handle all sensors going inward and outward automatically altogether. The other model that is for big sizes, all sensors can be moved separately one by one. During measurement operator will bring sensor holders to touch surface of the pipe one by one. Another design is bringing sensors to touch surface of pipe by pneumatic cylinder separately.

The only consumable for this technology is elastomeric caps that will come in contact with pipe surface because of making couplant media between sensor surface and pipe surface.