10 Method E6: Repeated bending

10.1 Object

The purpose of this test is to determine the ability of an optical fibre cable to withstand repeated bending.

Repeated bending of connectorized optical fibre cable involves testing as a unit, testing both the capabilities of the cable and the connector. This testing is defined by IEC 61300-2-44. Refer to that standard for testing of connectorized assemblies.

10.2 Sample

10.2.1 Sample length

The sample length shall be sufficient to carry out the specified test. When only physical damage is to be evaluated the length may range from 1 m (for example for small diameter cords or duplex cables) to 5 m (for larger diameter cables). Longer lengths may be necessary to permit optical measurements.

10.2.2 Termination

The sample shall be terminated at each end in a manner such that the fibres, sheathings and any strain members are clamped together in a representative manner. The clamps on the bending apparatus may be adequate, a connector may be used or the sample may be long enough that no restraint is needed.

10.3 Apparatus

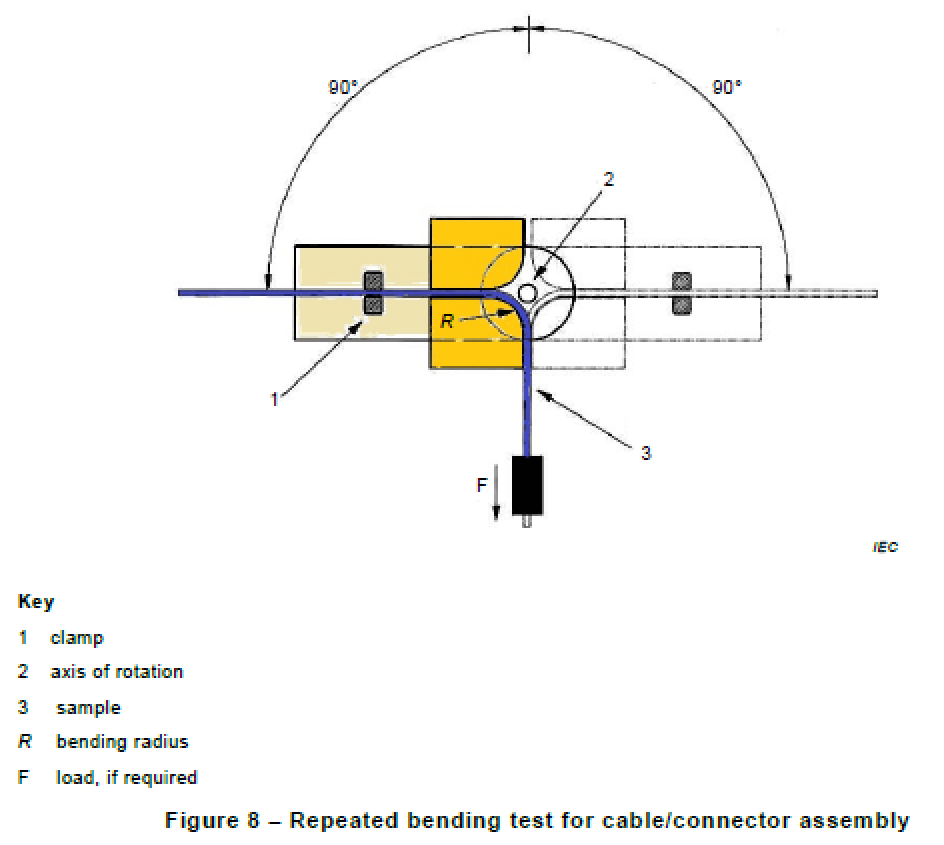

The apparatus shall permit a sample to be bent backwards and forwards through angles up to 180°, the two extreme positions making an angle of 90° on both sides of the vertical, whilst the sample is subjected to a tensile load. If no tensile load is specified, a manual tension sufficient to keep the sample in contact with the mandrel may be used. For testing cable, a suitable apparatus is shown in Figure 8. Other equivalent apparatus may be used.

Unless otherwise specified in the detail specification, the bending radius of curvature shall be a maximum of 20 times the cable diameter or the minimum mandrel radius, whichever is greater. The minimum mandrel radius shall be 75 mm for outdoor cables, and 75 mm or 25 mm shall be agreed for indoor cables between the customer and the supplier The bending arm shall have an adjustable clamp or fixture to permit holding the cable securely during the entire test, without crushing the optical fibres or inducing optical loss. A connector may be used to hold the cable on the bending arm, but for this test it is not considered part of the specimen under test. See IEC 61300-2-44 for an appropriate apparatus.

The apparatus shall be capable of cycling. Displacing the sample from the vertical position to the extreme right position, then oscillating to the extreme left position and returning to the original vertical position is considered to be one cycle. Unless otherwise specified in the detail specification, the bending rate shall be approximately one cycle in 2 s to 5 s. The apparatus shall include any optical test equipment needed to measure the changes in optical performance as required in the detail specification, and specified in Method A (transmitted power) of IEC 60793-1-46:2001.

10.4 Procedure

Unless otherwise specified, the conditions for testing shall be in accordance with standard atmospheric conditions.

The procedure can be defined as followed:

a) precondition the sample at standard atmospheric conditions for 24 h;

b) fix the sample to the apparatus, as such shown in Figure 8;

c) apply the load, as required by the detail specification;

d) measure acceptance criteria parameters to establish baseline values;

e) carry out the number of cycles of repeated bending specified;

f) carry out acceptance criteria parameter measurements. If necessary, the sample may be removed from the apparatus for visual examination.

10.5 Requirements

The acceptance criteria for the test shall be as stated in the detail specification. Typical failure modes include loss of optical continuity, degradation of optical transmittance or physical damage to the cable.

10.6 Details to be specified

The detail specification shall include the following:

a) number of cycles;

b) mass of the weight tensile load, if applicable;

c) bending radius R, if different to that already specified;

d) specific temperature if other than standard atmospheric conditions;

e) maximum allowable change in optical transmittance, during and after the test if required.

Repeated Bending tester, according to IEC 60794-1-21 Method E6

- Bending angle +-90 degrees

- Frequency 10-30 cycles/min

- Bending radius 75, 200, 300 mm (other sizes on request)

- Basic model is with a digital indicator (touch screen on request)

- Digital definition of number of cycles