14 Method E10: Kink

14.1 Object

The purpose of this test is to determine the minimum loop diameter at the onset of the kinking of an optical fibre cable.

NOTE Testing has indicated that the results of this test for cable have limited reproducibility. It is advised that it should be used with caution and that any minimum kink requirement be conservative.

14.2 Sample

The sample length shall be sufficient to carry out the specified test.

14.3 Apparatus

No particular apparatus is required. It is useful to loosely restrain the cable at the crossing point of the loop.

14.4 Procedure

Unless otherwise specified, the conditions for testing shall be in accordance with standard atmospheric conditions.

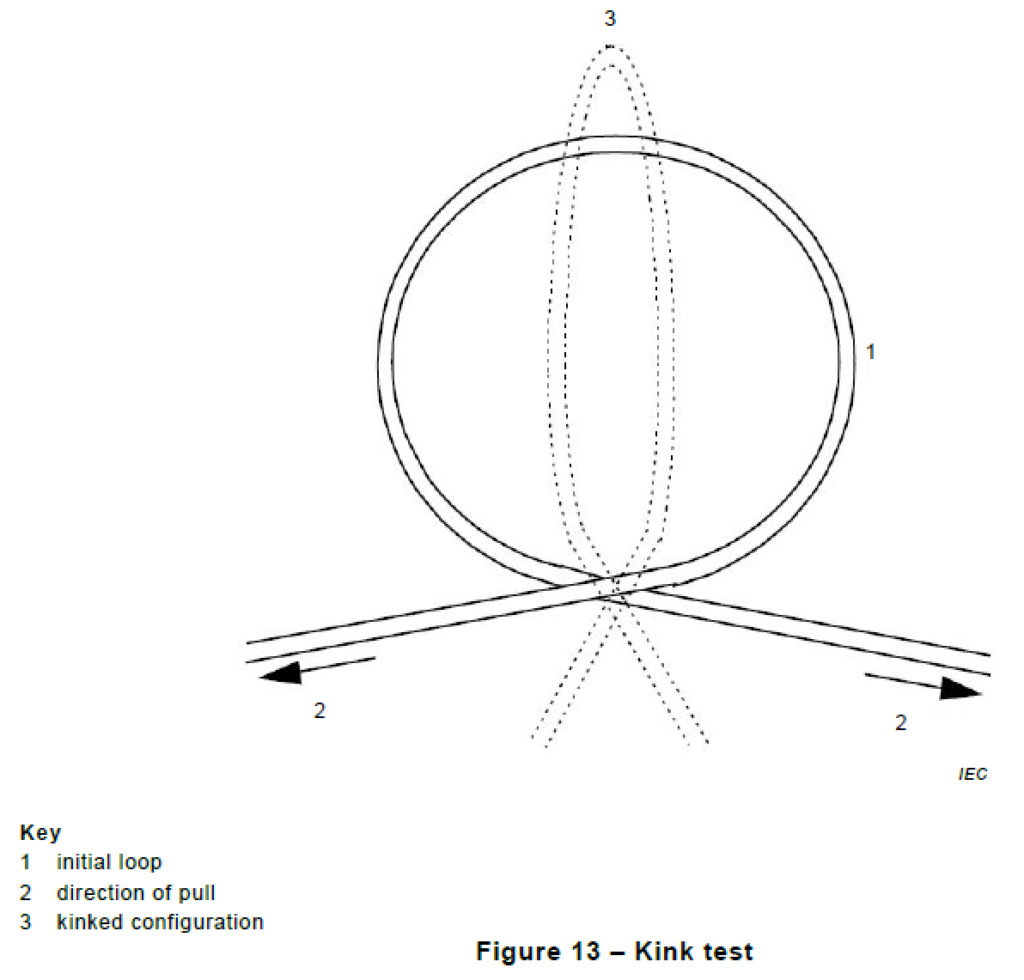

A loop shall be made (see (1) in Figure 123). The diameter of the loop shall be reduced to the onset of kinking by pulling slowly on the two ends (see (2) in Figure 13). The forces at the bottom of the loop shall be applied in one plane.

When the kinking begins, stop pulling.

Measure the length of the cable in the loop, C, beginning and ending at the crossover point. Calculate the equivalent loop “diameter” by applying the formula:

14.5 Requirements

No kink, as shown in (3), in Figure 123, shall occur at diameters greater than the specified minimum.

14.6 Details to be specified

The detail specification shall include the following:

a) minimum loop diameter at which no kink shall occur;

b) temperature;

c) number of samples to be evaluated.

Kink Tester According to IEC 60794-1-21 Method E10

Optical Fiber Cable Kink Testing Machine is used to determine the loop diameter at the onset of the kinking of an optical fiber cable in accordance with IEC-60794-1-2-E10.

· Pulling head stroke: 50-500 mm

· Pulling speed: 0 – 100 mm/s

· Transparent cover: 1000 x 700 mm

· Display: 7inch touch screen

· Save test results to internal memory