7 Method E3: Crush

7.1 Object

The purpose of this test is to determine the ability of an optical fibre cable to withstand crushing.

7.2 Sample

The sample shall be of a length sufficient to carry out the specified test.

7.3 Apparatus

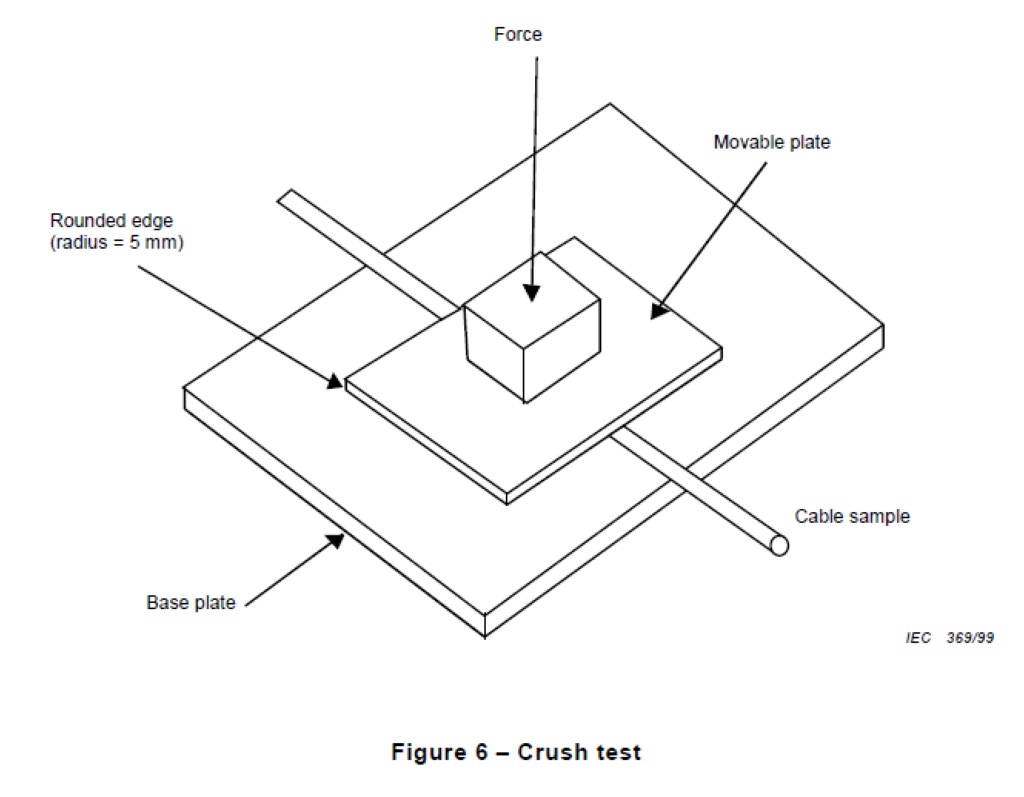

The apparatus shall allow a sample of cable to be crushed between a flat steel base plate and a movable steel plate which applies the crushing force uniformly over a 100 mm length of the sample.

The edges of the movable plate shall be rounded with a radius of about 5 mm. The edges are not included in the 100 mm flat part of the plate. A suitable apparatus is shown in Figure 6.

7.4 Procedure

The cable sample shall be mounted between the plates so that lateral movement is prevented, and the force shall be applied gradually without any abrupt change. If the force is applied in incremental steps, these shall not exceed a ratio of 1,5:1.

Unless otherwise specified in the detail specification, the test shall be performed three times, the force being applied on the specimen at three different places not less than 500 mm apart, without rotating the cable.

If requested in the detail specification, an additional or alternative test may be performed by inserting one or more steel mandrels (25 mm in diameter, unless otherwise specified in the detail specification) perpendicular to the sample, to represent particular operational conditions. Unless otherwise specified, the conditions for testing shall be in accordance with standard atmospheric conditions.

7.5 Requirements

The acceptance criteria for the test shall be as stated in the detail specification. Typical failure modes include loss of optical continuity, degradation of optical transmittance or physical damage to the cable.

7.6 Details to be specified

The detail specification shall include the following:

a) total force applied;

b) duration of application of the force;

c) number of tests;

d) spacing between test places;

e) configuration of mandrels, if used.

Crush Tester for Optical Cable According to IEC 60794-1-2/ E3

- Loading speed 0-200 mm/min

- Crosshead travel 200 mm

- Load measuring C3 class loadcell

- Displacement measurement

- Software is included

- Graphing and saving all data of force and displacement on Windows-based software

- Report in MS Excel

- Connection to computer is USB port

- The computer is not included

- Loading plate according to the standard