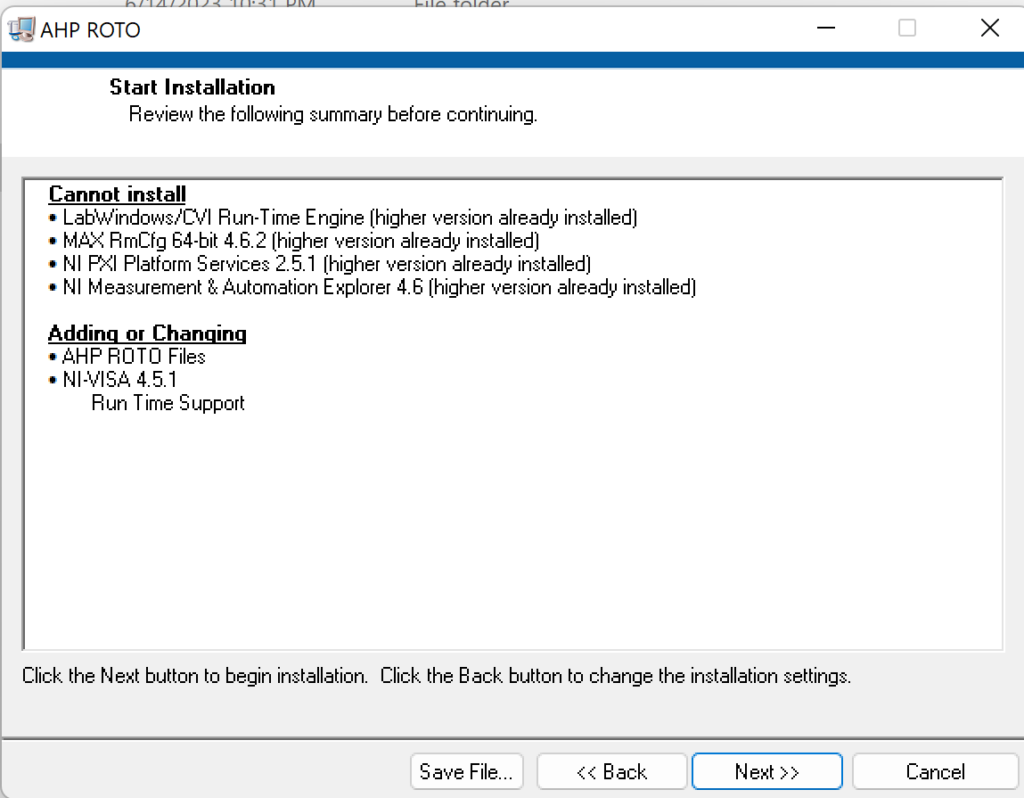

Software installation

1- Along with the machine you get a flash disk including software of AHP ROTO

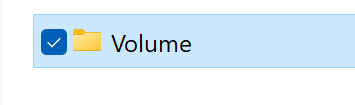

2- In the My Installer there is a folder named “Volume”

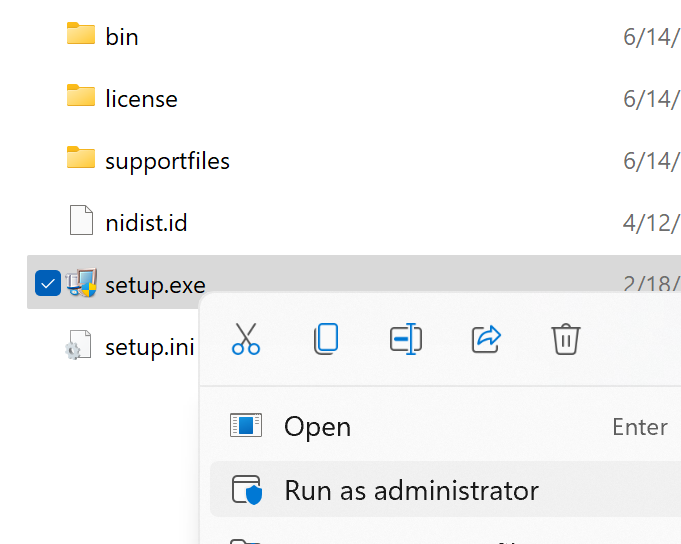

3- In this folder just right click “Set up.exe” and select “run as administrator”

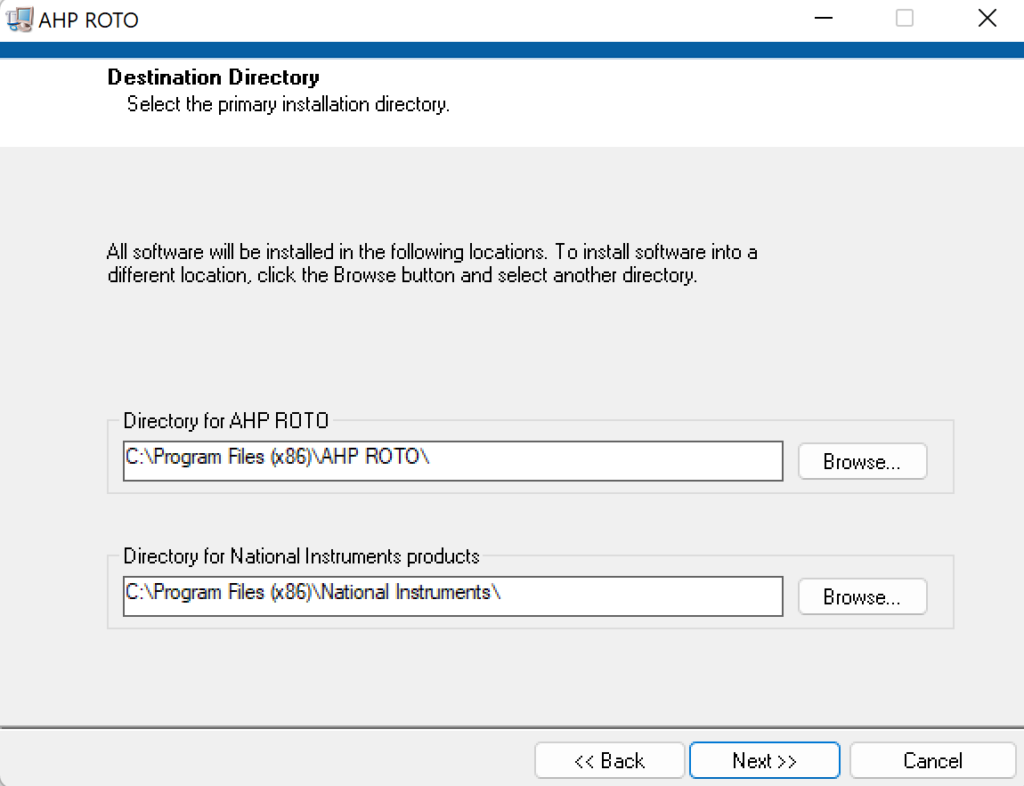

4- Don’t change default root for installation and continue till the end

5- Click on finish and installation is complete

6- Next you need to install the driver for RS485-USB converter [How to do this]

7- USB disk for the software is also a hardware lock key for software. Anytime you want to run the software, it should be connected to the computer unless you will get message “hardware lock is unplugged”

8- If the windows is 64 bit, default installation root for software is “C:\Program file (X86)” you need to also copy full folder of installation into “C:\Program files” unless you will get message of “hardware lock in unplugged”

9- After all this set the comm port number in setting page of software same as the virtual comm port you installed in No.6

10- Run the software it is ready to use

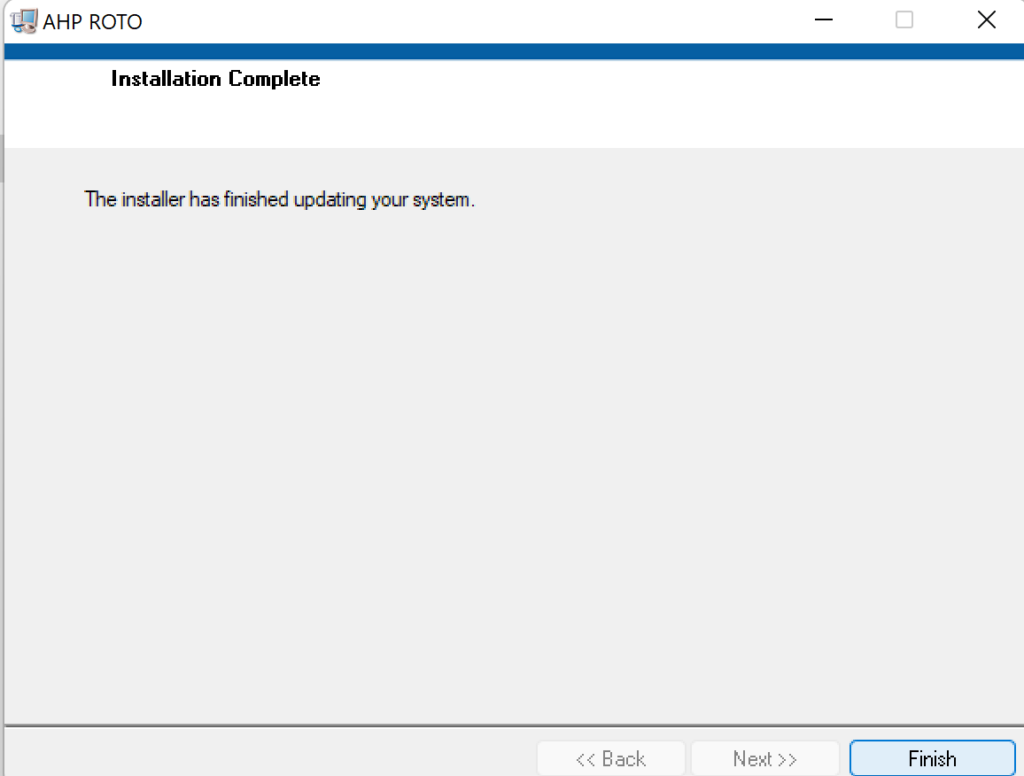

11- Input general parameters of test here(company,operator,customer,…..)

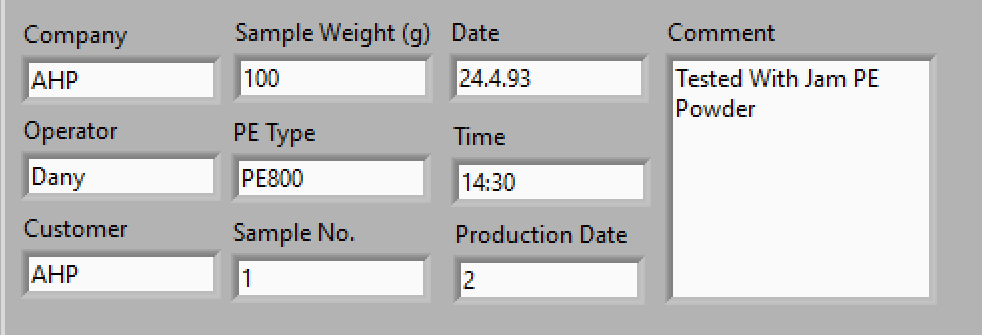

12- If you want to run the machine in single step turn on “manual” mode. set speed1(rpm) and speed 2(rpm) for the speed of two rotating axes and rotation will begin. Don’t forget to push run key on both axes frequency inverter on the control panel. Here you can also set the cabin temperature. Push the Start and Stop key for the process start and stop.

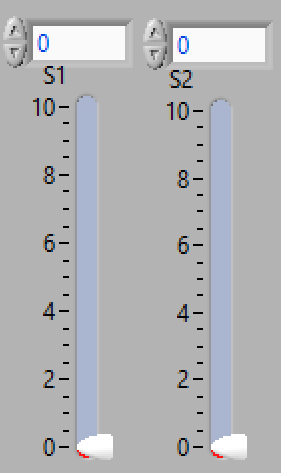

13- Using sliders you can also change the speed of rotation for both axes of rotation.

14- for the general parameters of the sample for testing you can save the data as .txt file and load in next runs. in this way no need to input general parameters one by one. When save don’t forget to add “.txt” to the end of file name.

15- When you clock on “STRAT” the run LED will be ON

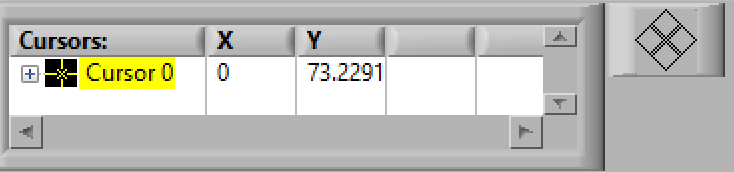

16- Graph has curser section to have any number of cursers on graph. right click on cursor and you have many function for changing it like color, thickness,….. If you right click in white area you can add any number of cursors to the graph.

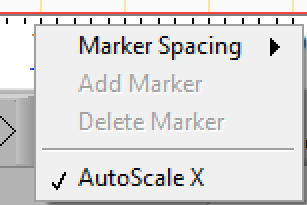

17- Graph vertical and horizontal axes has function of setting to auto “suto scale” or setting the limits manually. right click in each of the axes and there is a function named “autoscale” make it on or OFF (if you want to set the limits of axes manually)

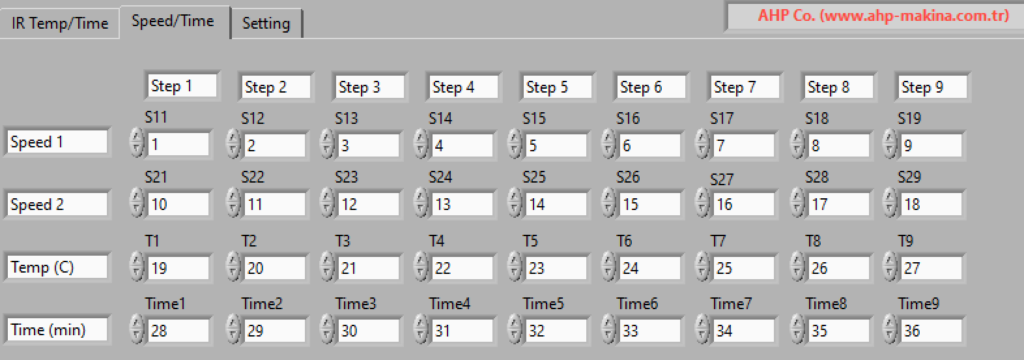

18- There is page for multistep set. Here you can have settings for rpm of two axes, temp and time up to 9 steps. In this mode settings of all 9 steps will be applied one by one.

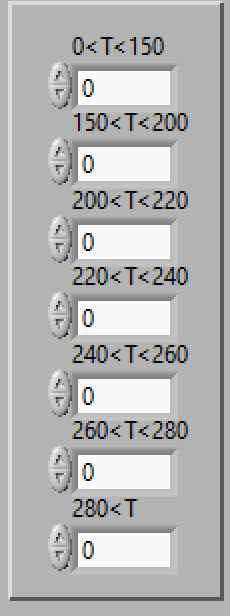

19- In the setting page there is offset settings for different temp ranges. If you want to calibrate temp in different ranges. you can set offset value here.

20- Filters make the graph more smooth and remove noises from data

21- After you clicked on “STOP” you can have report in MS WORD as one page including setting data table for multi steps, general sample data and also graph.

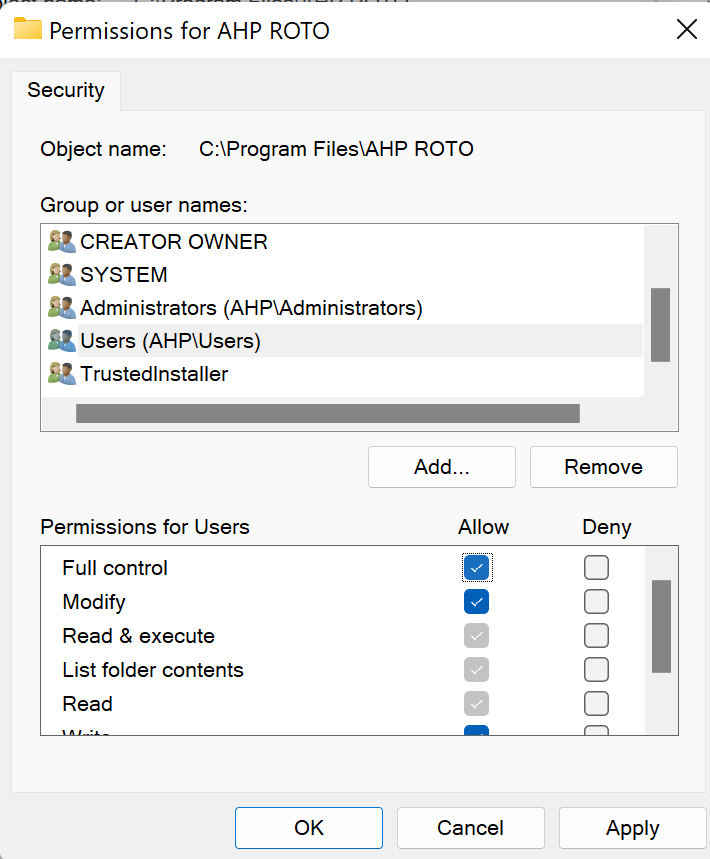

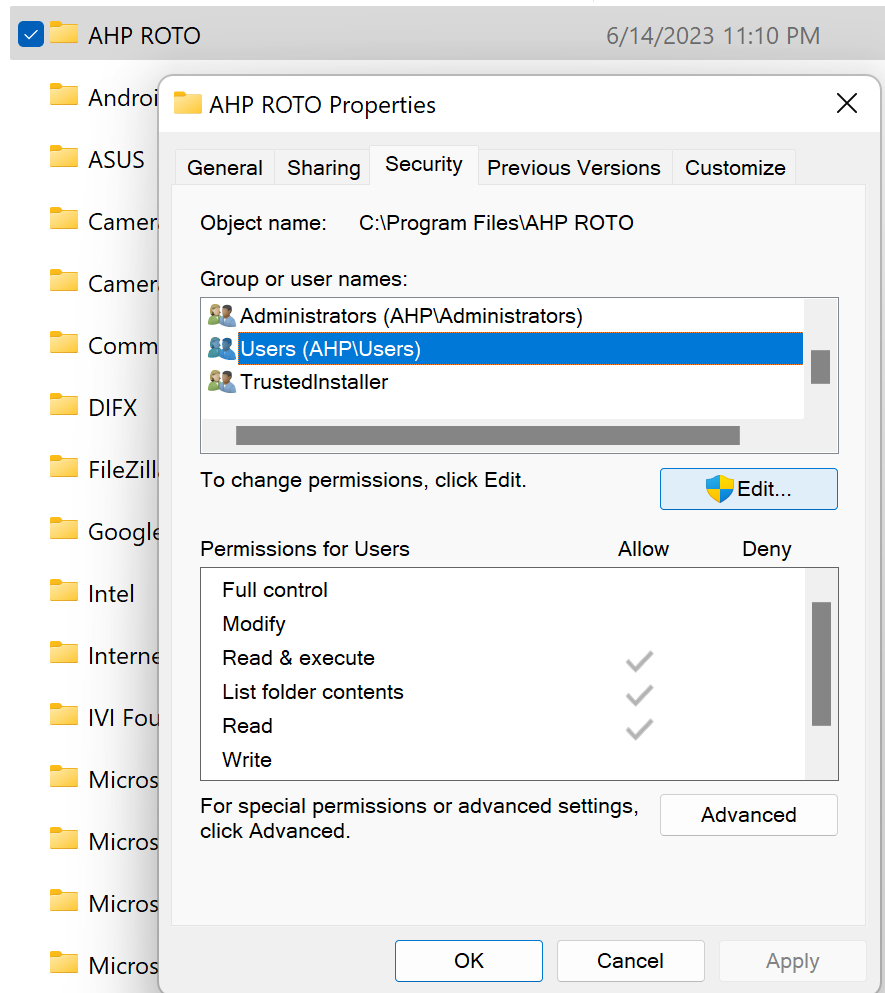

22- If you click on this key and don’t have report in hand need to open security access to the folder of installation as below: in the root C:\Program files right click on folder “AHP ROTO” then select “properties” in the security tab:

Select users, then click on “Edit”. In the next page again select “users”. in the buttom of page “Permissions for users” click on “Allow” in front of “Full control”. Then apply and “OK. “

23- Before turning off the machine always click on “Quit”. unless last settings of PLC will be remained and in next Turn on of machine it will start heating.