4 Apparatus

4.1 Testing machine capable of applying load in vertical and/or horizontal direction and with a measuring

accuracy of ± 3 %.

4.2 The accuracy of positioning of components shall be within ± 2 mm.

4.3 Devices to have the pallets secured for test 6.3 and 6.5.

4.4 Instrument for measuring deformation with an accuracy of 0,2 mm.

4.5 Determination of moisture content in accordance with ISO 3130, prEN 13183-1 and prEN 13183-2.

5 Procedure

5.1 Carry out the tests either at a constant rate of loading of (2 ± 0,2) kN/min, or constant speed of the testing machine loading head of (30± 5) mm/min.

5.2 In connection with the tests, the moisture content of the timber shall be recorded.

5.3 The pallet collars tested shall be discarded after every test.

6 Testing

6.1 General

Tests shall be conducted as follows:

- bending stiffness and strength;

- tensile testing of hinge and rivet joint (not applicable to pallet collars with rigid corner bars);

- shear loading of supporting lips;

- load testing of stacked pallet collars.

6.2 Bending stiffness and strength

6.2.1 Test selection

Bending stiffness and strength tests shall be performed on the appropriate type of pallet collar:

- rigid side pallet collars;

- folding hinged pallet collars.

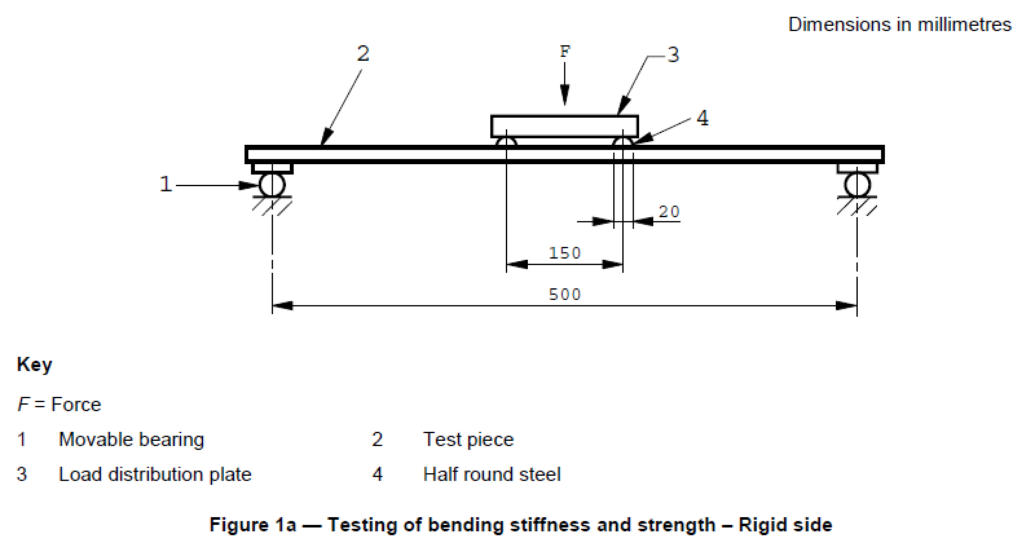

6.2.2 Test 1a — Bending stiffness and strength — Rigid side pallet collars

Three tests shall be performed with test pieces taken from different collar sides.

6.2.3 Apparatus

Test arrangement according to Figure 1a

6.2.4 Testing procedure

A piece of a collar side about 600 mm long is placed flat and horizontal on supports movable in the long side direction of the test piece.

With the supports parallel two forces acting across the whole width of the test piece are applied against the test piece.

The force is transferred to the test piece by the half round steel profiles of 20 mm diameter.

The plane surface shall be turned against the test piece. The half round steel profiles shall be symmetrically placed with a relative position to each other of 150 mm.

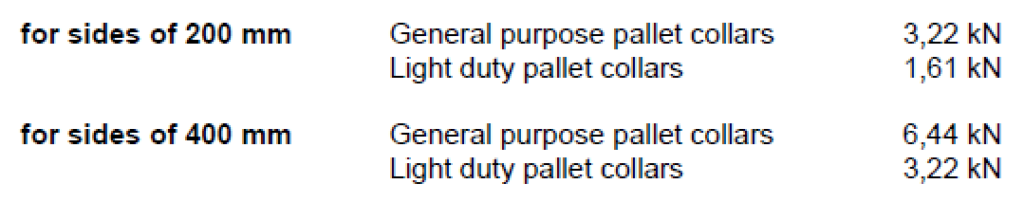

The force is increased continuously to:

At this force the bend at the middle of the test piece is measured. The force is then increased until the test piece breaks.

6.2.5 Performances requirements

For general purpose collars at a force of 3,22 kN respectively 6,44 kN the deflection at the centre shall not be more than 8 mm. For light duty collars the deflection at the centre shall not be more than 8 mm at a force of 1,61 kN respectively 3,22 kN.

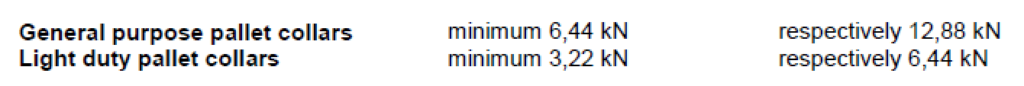

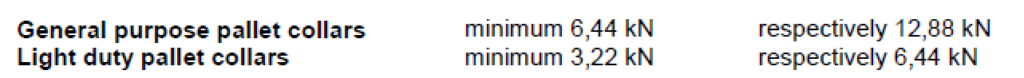

The breaking strength shall be for:

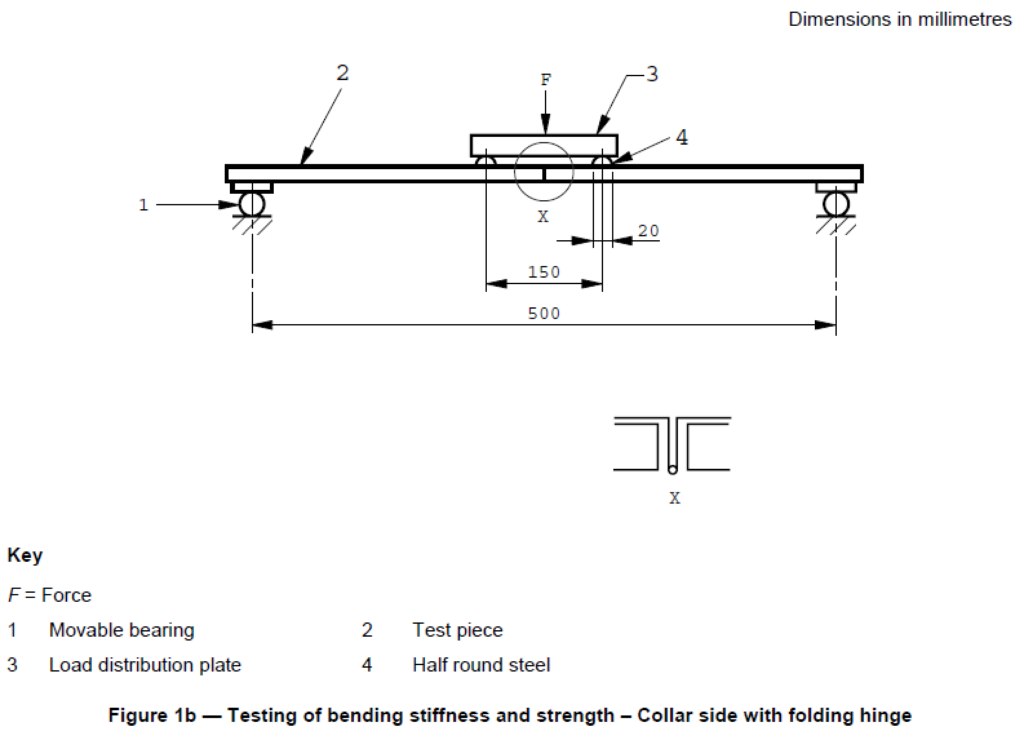

6.2.6 Test 1b – Bending stiffness and strength test – Collar side with folding hinge

Three tests shall be performed with test pieces taken from different collar sides.

6.2.7 Apparatus

Test arrangements according to Figure 1b.

6.2.8 Testing procedure

A piece of a collar side, about 600 mm long, is placed flat and horizontal with the hinge down on supports movable in the long side direction of the test piece.

With the supports parallel two forces acting across the whole width of the test piece are applied against the test piece.

The force is transferred to the test piece by the half round steel profiles of 20 mm diameter. The plane surface shall be symmetrically placed at a relative distance of 150 mm whatever is the most suitable for the design of the hinges.

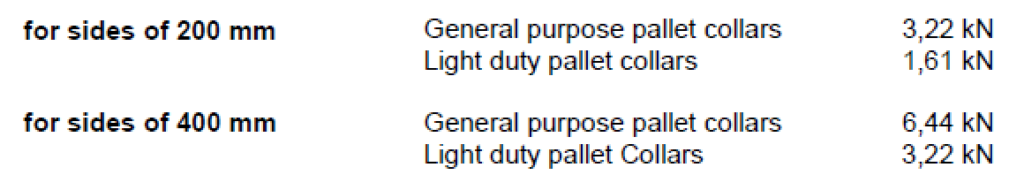

The force is increased continuously to:

At this force the deflection at the centre of the test piece is measured. The force is then increased until the test piece breaks.

6.2.9 Performance requirements

For general purpose collars at a force of 3,22 kN respectively 6,44 kN the deflection at the centre shall not be more than 8 mm. For light duty collars the deflection at the centre shall not be more than 8 mm at a force of 1,61 kN respectively 3,22 kN.

The breaking strength shall be for:

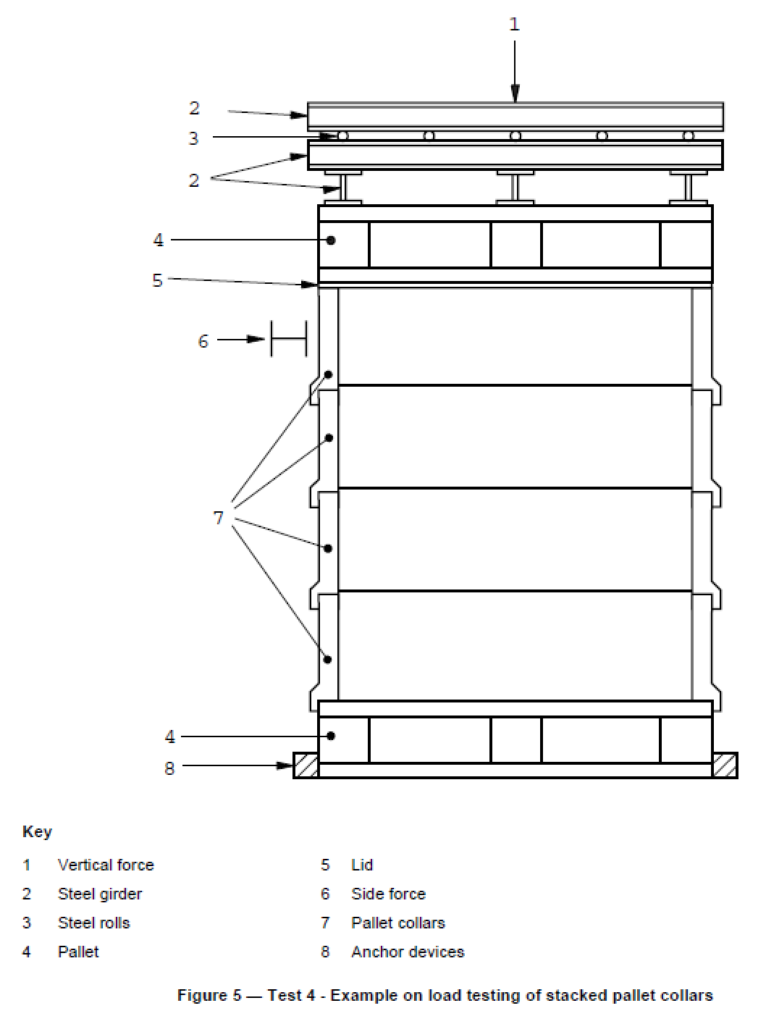

6.5 Load testing of stacked pallet collars

6.5.1 Procedure

Load testing of stacked pallet collars shall be carried out as 6.4.1 to 6.4.4. Where laboratories required to perform this test have smaller testing facilities, this may be carried out in accordance with 6.4.4 to 6.4.7.

6.5.2 Test 4 — Load testing of stacked pallet collars — Standard test

6.5.2.1 Apparatus

Test arrangement according to Figure 5 consisting of:

a) standard pallet mounted rigidly at a solid horizontal support;

b) four 200 mm pallet collars or two 400 mm pallet collars.

The side force is applied with a rigid steel girder with a width of 100 mm and a length greater than the collar side.

The vertical force is applied with a test rig consisting of:

a) a lid for pallet collar;

b) a standard pallet;

c) three rigid steel girders whose length = the width of the pallet + 50 mm;

d) two rigid steel girders whose length = the length of the pallet + 50 mm;

e) five steel rollers of 50 mm whose length equals the width of the pallet.

6.5.2.2 Testing procedure

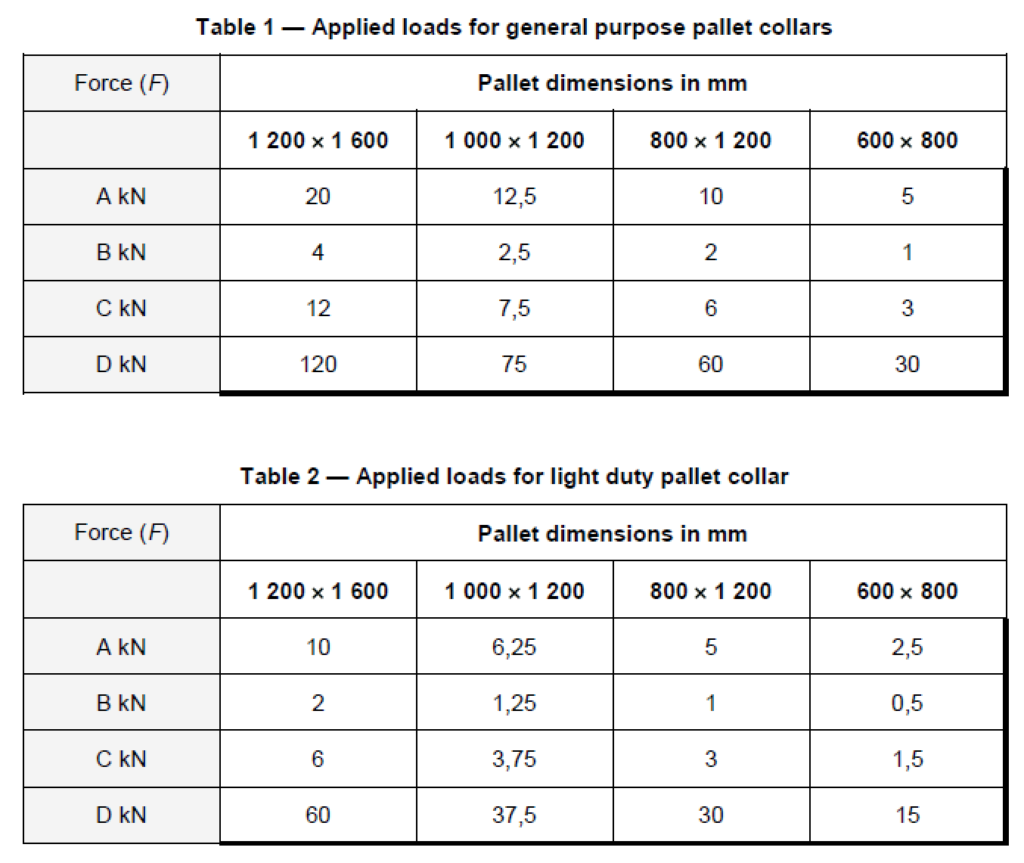

One test is performed using the loads specified in Table 1 and Table 2.

One short side in the uppermost pallet collar is loaded with horizontal force. The force shall act on the half height of the collar side and shall be transmitted to the collar by a rigid steel girder in the way shown in Figure 5.

Before testing the pallet collars are placed in a way so as to eliminate play between them.

The vertical force is continuously increased to A kN. Then a horizontal force of B kN is added whereupon the displacement of the uppermost pallet collar in both the vertical and the horizontal plane are measured. The vertical force and the horizontal force are now increased in two further steps with A kN and B kN per step respectively. For every step the deformations mentioned shall be measured. With the horizontal force retained at C kN at the vertical force is increased until breaking.

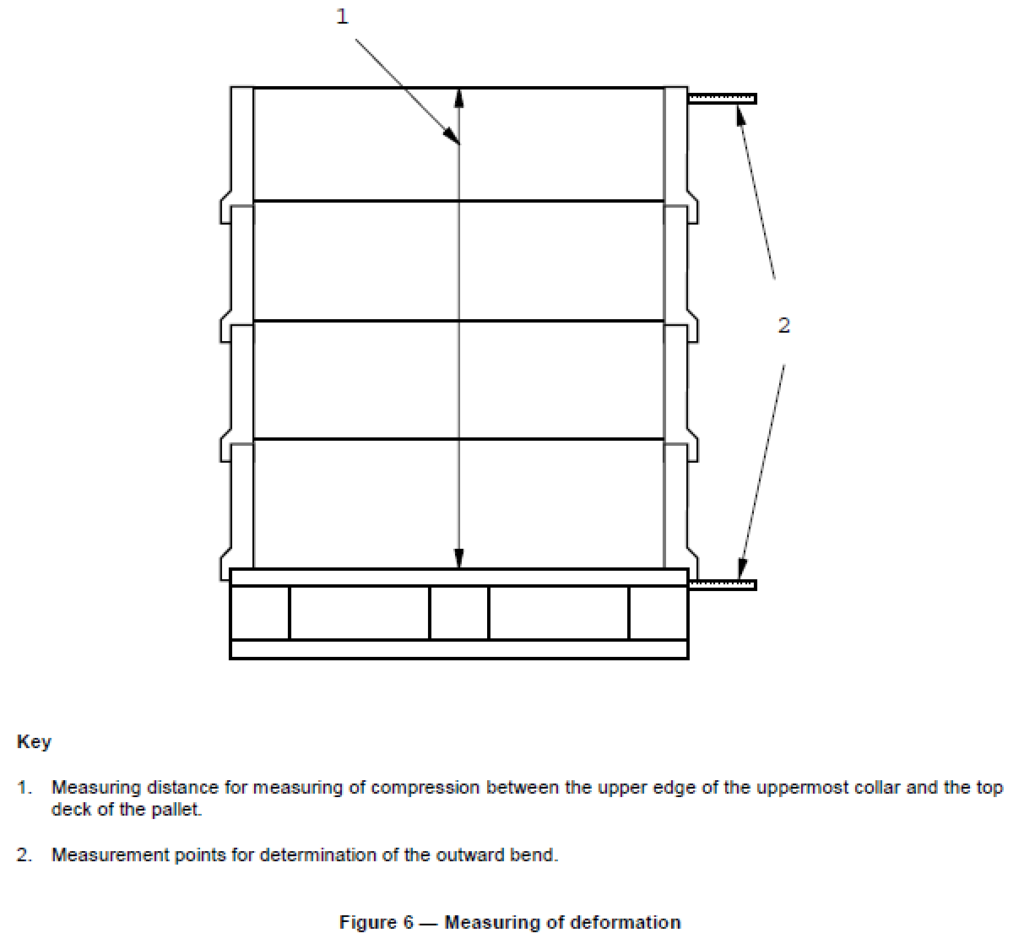

6.5.2.3 Horizontal deformation

The horizontal deformation is measured in millimetres between the upper edge of the uppermost collar and the pallet top deck according to Figure 6.

6.5.3 Performance requirements

The added deformation after applying the three loading steps shall amount to a maximum of 10 mm in the horizontal plane and 5 mm in the vertical plane. At break the vertical force shall be minimum D kN.

Testing Equipment

4-Column Pallet Tester with 5 Displacement Measurement Points According to ISO 8611

- Including software for automatic compression testing //

- According to ISO 8611 //

- Capacity maximum 100KN //

- Load resolution 1/10000 //

- Displacement resolution 1/1000 //

- Displacement accuracy ≤0.5% //

- Speed range 1-100 mm/min //

- Max crosshead travel 60 cm (Between test platens) //

- Maximum travel distance of linear transducers 300mm //

- Self align loading plate //

- Magnetic base for placement of measurement point to any location under sample piece //

- German ball screws //

- Two ball screws and 4 chrome shaft guides //

- PLC controlled //

- Suitable for stacking test //

- Forklift and compression tests //

- Windows-based software //

- Reporting in MS EXCEL //

- Overload protection //

- Travel limit switches //

- Servomotor controlled //

- Hard chrome guide shafts //

- Linear guide for displacement of linear transducers on both sides of measurement table //

- Power consumption about 1KW //

- Power 220V-50Hz //

- Load cell 100KN //

- Training video is included //

- Windows based software //

- Connection to PC is USB port //

- Compression pressure plate 1300x1300mmx100mm //

- Connection port is USB //

- Software is included //

- Software will do full test cycle automatically //

- Reporting in MS EXCEL //

- Basic machine has only one displacement measurement point //

- Machine has linear transducer input for displacement measurement in 5 points that will be added according to customer request //

- Laptop and ergo arm for assembly will be quoted separately //

- Includes test setup for bending test according to ISO 6259-1(Figure1) //

- Includes test setup for forklifting test according to ISO 6259-1 (Figure2) //

- Includes load applicator for corner compression test according to ISO 6259-1 (Figure3) //

- Includes test setup for deck strength and stiffness test according to ISO 6259-1 (Figure4) //

- Includes test setup for bottom deck strength and stiffness test according to ISO 6259-1 (Figure5) //

- Includes test setup for wing pallet bending test according to ISO 6259-1 (Figure 6) //

- Online distance remote support for software //

- Side force application is an option (need to ask for quotation) //

Bending stiffness and strength Tester — Rigid side pallet collars according to EN 13545 – 20KN

- According to ISO 527 , ASTM D 638 //

- Servo motor controlled //

- Ball screw for moving mechanism //

- Double column //

- USB port for computer connection (computer is an option) //

- Windows-based software //

- Grips as per customer request for different products (as an option) //

- Easy operation and clear visualization (test curves, calculations) //

- Easy to change the grips via male-female connection //

- Accuracy ±0.5% of full scale //

- Precise self-cleaning ball-screw //

- Brush-less servo motor quarantine maintenance-free operation //

- Easy calibration of load-cell //

- Socket connection of extensometer as standard option //

- Force Capacity maximum 20KN //

- Loadcell of the machine is 20KN //

- Load resolution 1 over 10000 //

- Displacement accuracy ≤0.5% //

- Speed range 0.01-200 mm/min //

- Cross head travel 900 mm (without grips) //

- Calculation of yield, UT, elongation at break, and all other tensile and compression parameters by software //

- Timing belt force transmission system for low noise //

- Hard chrome guide shafts //

- Overload protection //

- Travel limit switches //

- Manual high-speed up and down detachable hand key //

- Distance between two columns 350mm //

- Power consumption is about 1000W //

- Power 220V-50Hz //

- Training video included //

- Report in MS EXCEL //

- Easy calibration by operator //

- Remote support for software //

- Including test fixture according to EN 13545- 6.2 //

- Including a linear transducer for displacement measurement in the middle part of the sample piece- 50mm travel distance //