J.1 General

This test consists of measuring the reduction of the specific electrical coating resistance after the coating has been conditioned in an electrolyte.

J.2 Apparatus

The test is carried out either by bonding and sealing a plastic pipe segment to the surface of the sample or by placing a pipe section horizontally in a plastic container with lateral openings of suitable size. The gap between the container and pipe shall be closed with a suitable sealant.

The test medium shall be a 0,1 mol/l NaCl solution and should cover the pipe surface to a depth of about

100 mm. The surface of the counter electrode shall be a least 10 cm². Furthermore, a direct current supply

having a minimum output voltage of 50 V and an ammeter and a voltmeter are necessary. The immersed test surface should be at least 0,03 m².

J.3 Procedure

J.3.1 Test piece preparation

Pipe segments or sections shall be used as test pieces. The test pieces shall be subjected to high-voltage

continuity testing prior to this test.

J.3.2 Procedure and evaluation

The test piece shall be exposed to the test medium for 100 days at 23 °C.

For the purposes of measurement, the positive pole of the direct current source shall be connected to the

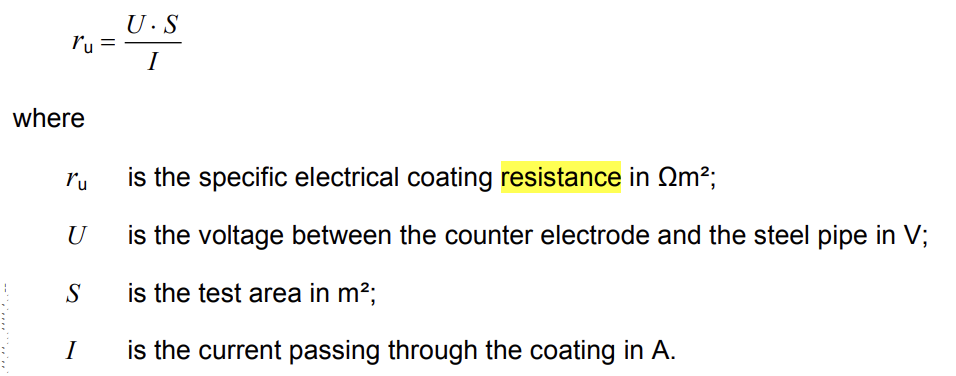

steel substrate and the negative pole shall be connected to the counter electrode. During measurement the counter electrode shall be immersed in the test medium. The specific electrical coating resistance ru shall be calculated from the following equation:

The voltage is to be applied only at the time of measurement.

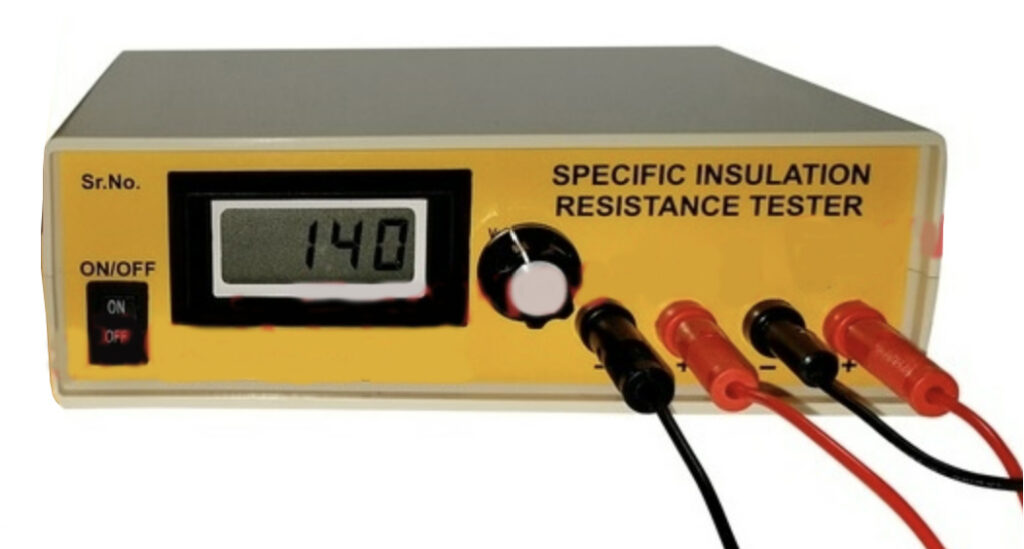

Specific Insulation Resistance Tester for Coatings According to DIN 30670

- Insulation resistance tester

- Plexiglass chamber

- Gun and acrylic sealer

- 100-600 V

- Output current up to 1 A