Calibration of Force

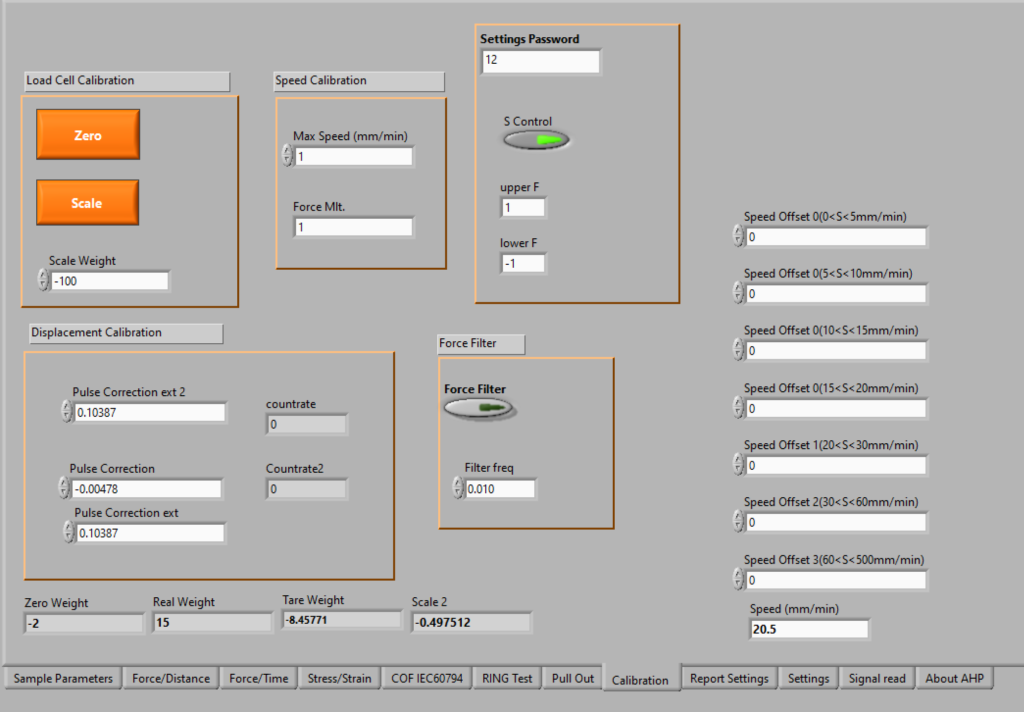

Run the software and go to calibration tab as below:

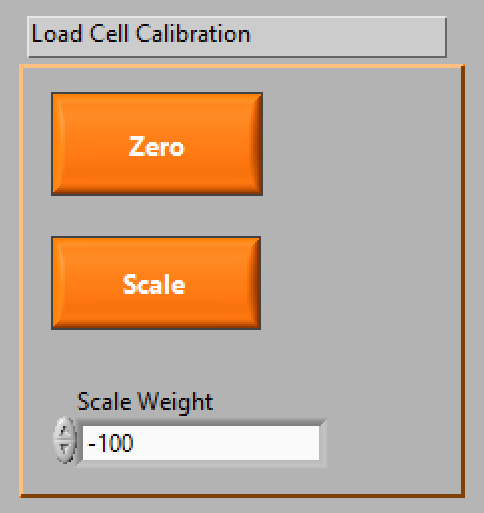

There is a section named Load cell calibration.

When there is no load on the load cell click on “ZERO” Key.

Then apply a weight of definite load on the loadcell

For example if the weigh is 20kg then you will write on “Scale Weight” the value of 20*9.81=196.2N. This is the weight value in N. Then Click on “Scale” key.

After this you can click on “Quit” key to save setting.

Calibration of Displacement

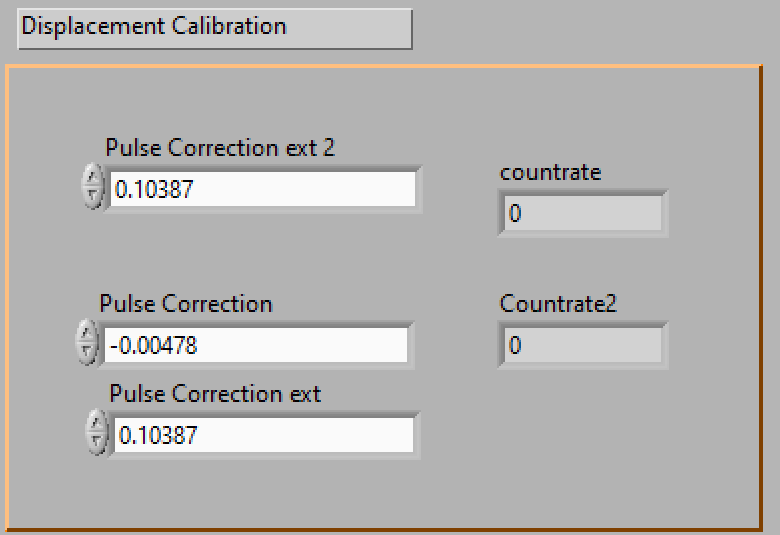

There is a section named “Displacement calibration”

Firs set the “Pulse Correction” to 0.00478. Then mark the place where the moving jaw is.

Then Zero displacement by below key:

Then you marked the zero point on machine and set the displacement indicator of the software to zero. No move the moving jaw of the machine by some distance. and then mark the new point where the jaw is stopped. Measure the distannce between two marks on the machine to know how much the moving jaw is displaced. And see how much the software shows distance:

Divide this real moved distance of moving jaw by the software “Distance F(mm)” value and multiply this result by “Pulse correction” that was 0.00478 in the beginning. And then replace the new value to the old value of “Pulse correction” and click on “Quit” to save the settings.

Calibration of speed

In speed calibration section put the “max speed (mm/min)” to 100.

Then set the speed of machine to 100.

And then start the stopwatch and at the same time start the machine. Be noted clicking on Start and starting the stop watch need to be at the same time.

Then after 1 minute , stop the machine.

You see how much machine distance shows for 1 minute.

Then the speed is Distance F(mm)/min. This is the measured maximum speed. Then you need to replace this new maximum speed to the old one.

Then click on “Quit” to save settings.

Now you have all force, displacement and speed calibrated. be noted before calibration of speed you need to calibrate the displacement at first.