4 Material

4.1 PP-compound

The compound for pipes and fittings shall be PP-base material (homopoiymer or copoiymer) to which are added those additives that are needed to facilitate the manufacture of components conforming to the requirements given in this standard.

In orderto conform to national requirements on fire regulations other additives may be used.

Fabricated fittings or parts of fabricated fittings shall be made from pipes and/or mouldings conforming to this standard, except for the requirements for the wall thickness of fabricated fittings and/or mouldings from pp which conform to material, mechanical and physical characteristics as required in this standard.

4.2 Reprocessable and recyclable material

In addition to virgin material the use of own reprocessable material obtained during the production and testing of products conforming to this standard is perrnitted. External reprocessable or recyclable material shall not be used.

4.3 Melt mass-flow rate

The MFR of the base material shall be tested in accordance with ISO 1133:1997, condition M (test temperature: 230 °C, loading mass: 2,16 kg).

pipes and fittings intended to be used for mechanical joints shall be made from materials with an MFR as follows:

MFR (230/2,16) 3,0 g/10 min.

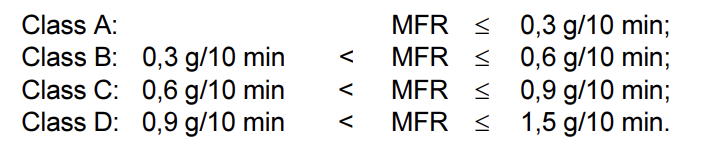

Materials for pipes and fittings for butt fusion joints shall be designated by the following classes with regard to the MFR:

Only pipes and fittings made from materials of the same or adjacent MFR-classes may be fused together.

4.4 Thermal stability

When tested in accordance with EN 728 using a test temperature of 200 °C, the oxidation induction time (OIT) of the material used for pipes and fittings intended for butt fusion shall not be less than 8 min.

7 Mechanical characteristics of pipes

7.1 General characteristics

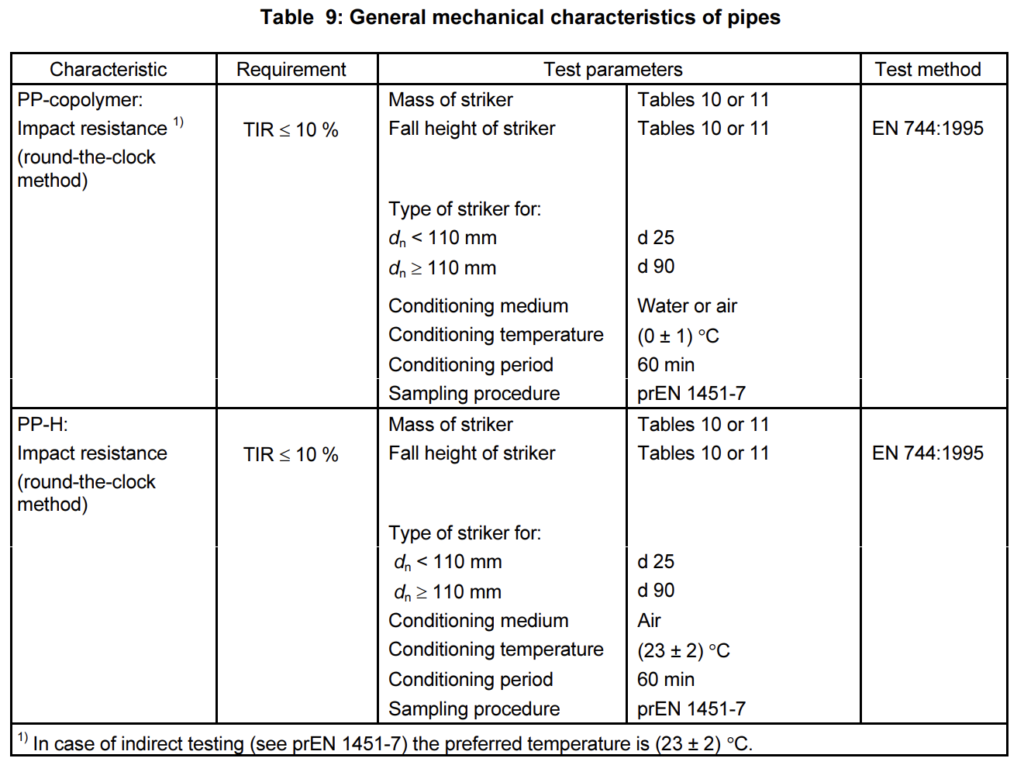

When tested in accordance with the test method as specified in Table 9 using the indicated parameters, the pipe shall have general mechanical characteristics conforming to the requirements given in Table 9.

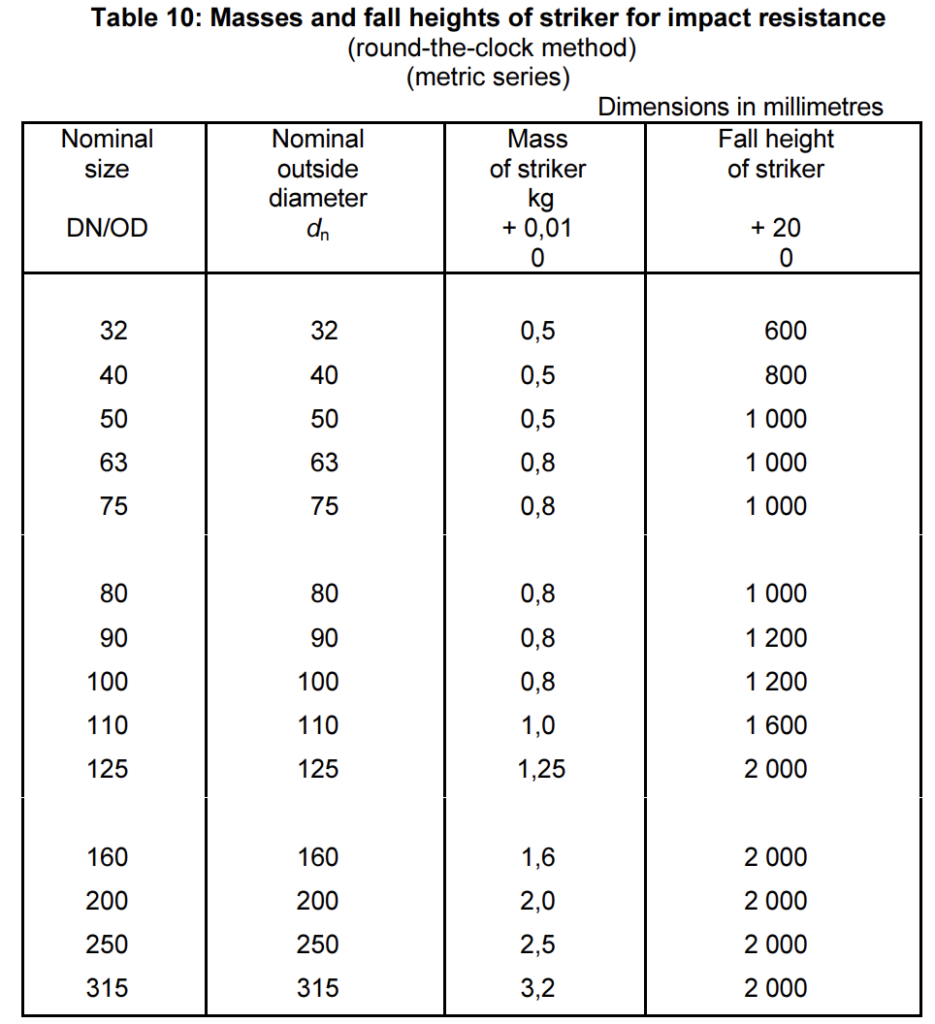

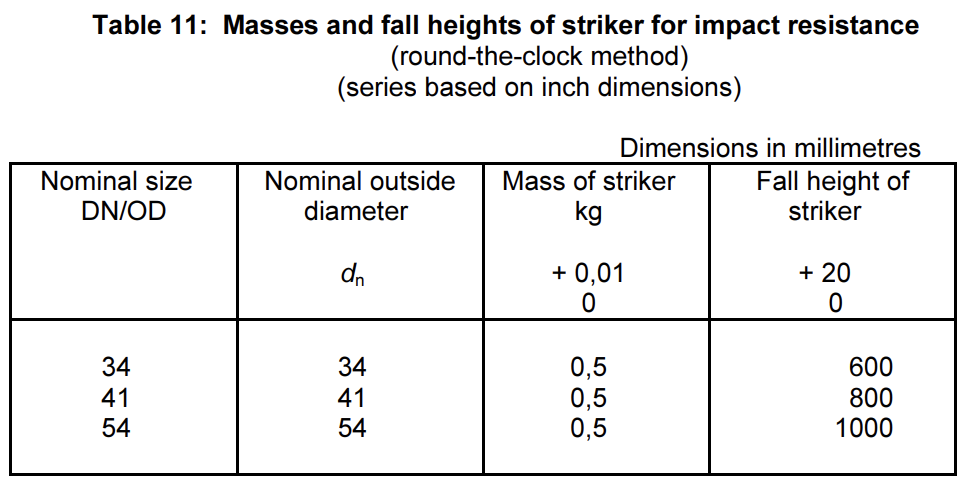

The mass and fall height of striker for determining the impact resistance (round-the-clock method) as specified in Table9aregiven in Table10 orTable11, as applicable.

8 Physical characteristics

8.1 Physical characteristics of pipes

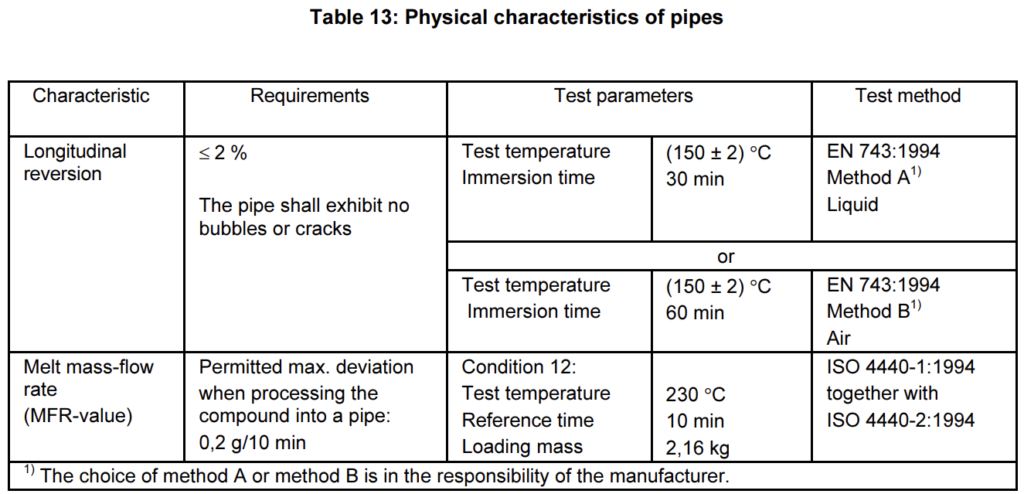

When tested in accordance with the test methods as specified in Tabie 13 using the indicated parameters, the pipe shall have physical characteristics conforming to the requirements given in Table 13.

8.2 Physical characteristics of fittings

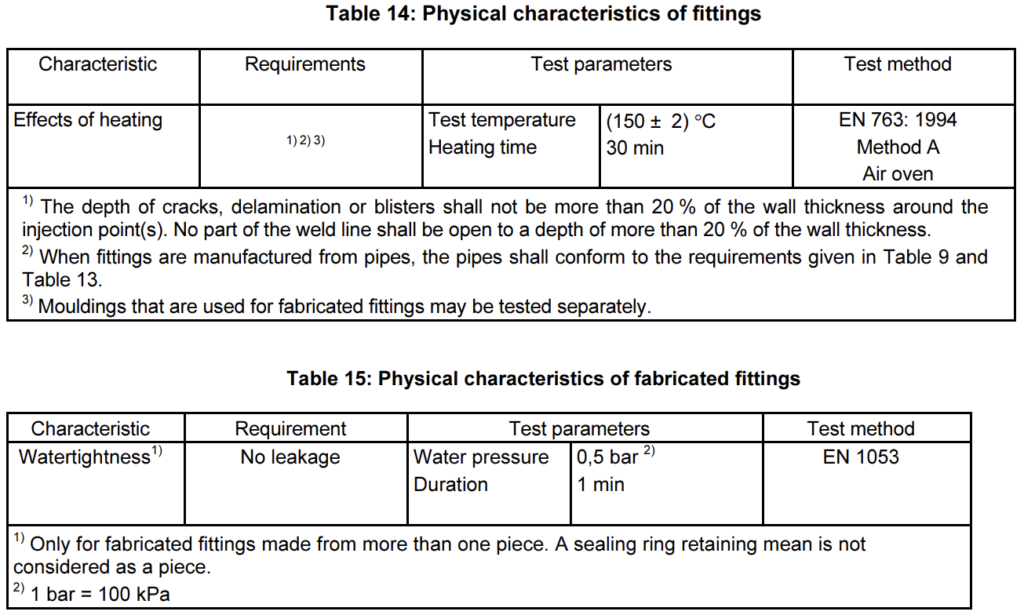

When tested in accordance with the test methods as specified in Table 14 and Table 15 using the indicated parameters, the fittings shall have physical characteristics conforming to the requirements given in Table 14 or Table 15, as applicable.

9 Performance requirements

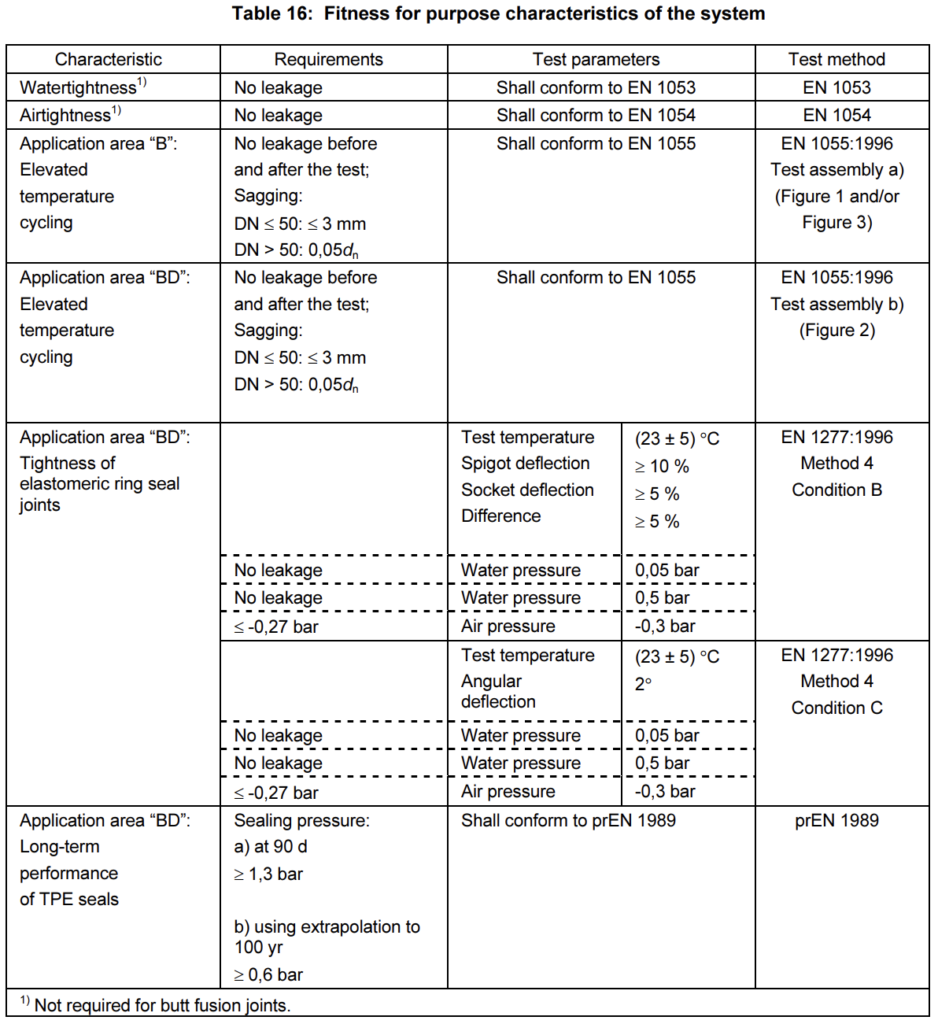

When tested in accordance with the test methods as specified in Table 16 using the indicated parameters, the joints and the system shall have fitness for purpose characteristics conforming to the requirements given in Table 16.

10 Requirements for application area “BD”

10.1 General

pipes and fittings intended to be used for application area “BD” shall conform to the requirements for application area “B” and additionally to the requirements given in this clause.

If national regulations require for use buried in ground within the building structure greater nominal outside diameters than 75 mm, these dimensions shall be taken into account.

For butt fusion joints, only those pipes and fittings (marked with “BD”) shall be used which are suitable for use inside buildings and buried in ground within the building structure.

10.2 Material characteristics

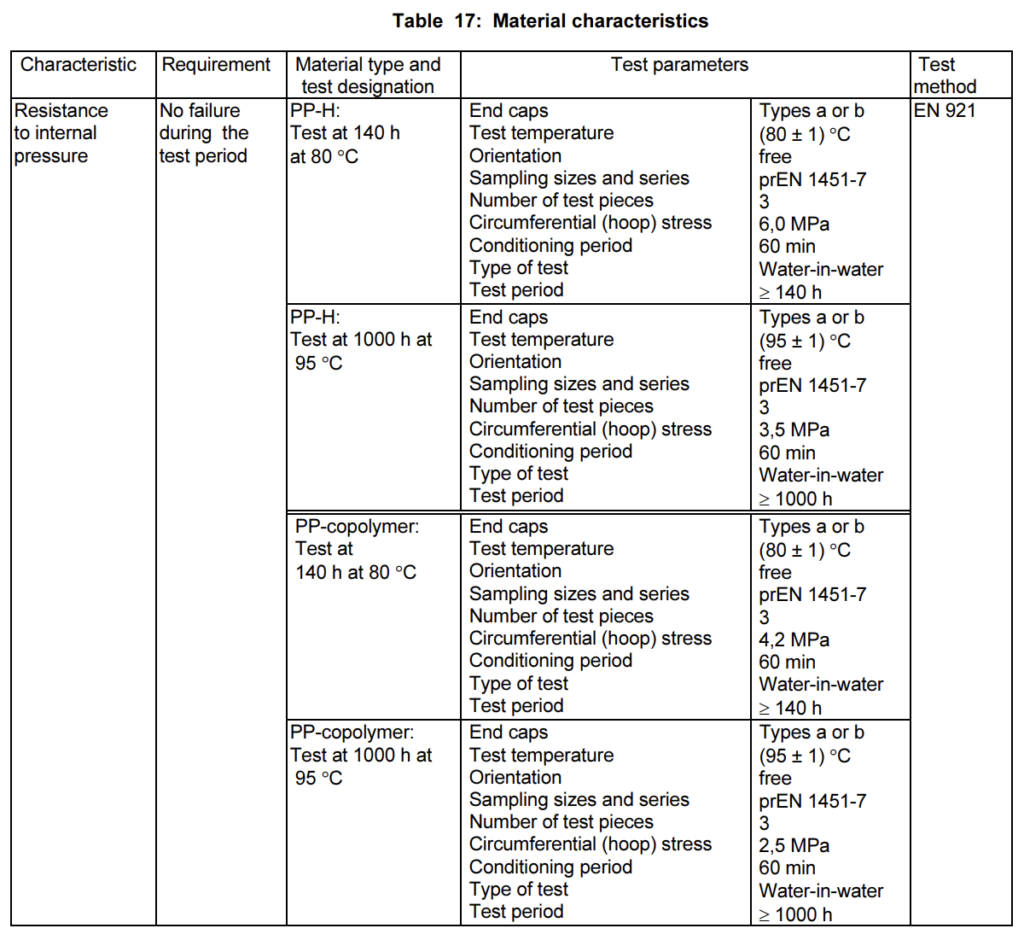

The material for pipes and fittings used for application area “BD” shall conform to the requirements for resistance to internal pressure as specified in Table 17. The material shall be tested in the form of a pipe.

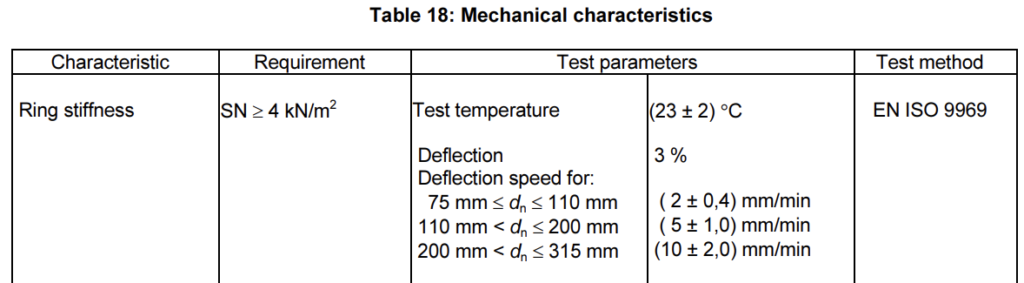

10.3 Mechanical characteristics

pipes used for application area “BD” shall conform to the requirements for ring stiffness as specified in Table 18.

Summary of Testing Equipment to Cover This Standard are As below:

- Dimensional measurement equipment for pipes and fittings

- MFI MFR Melt Flow Indexer ISO 1133

- DSC OIT Differential Scanning Calorimeter EN728

- Falling Weight Impact Tester EN 744

- Longitudinal Reversion (Hot Air Oven) EN 743

- Water Tightness Tester EN 1053

- Air Tightness Tester EN 1054

- Thermal Cycling tester EN 1055

- ISO Ring Stiffness Tester ISO 9969

- Hydrostatic Pressure Tester EN 921

- Hot Water Bath for Hydrostatic Pressure Tester EN 921

- SS304 End Caps

- Combinational Test for Seals EN 1277