6 Bend test

6.1 Test piece

The general provisions in Clause 4 apply.

6.2 Test equipment

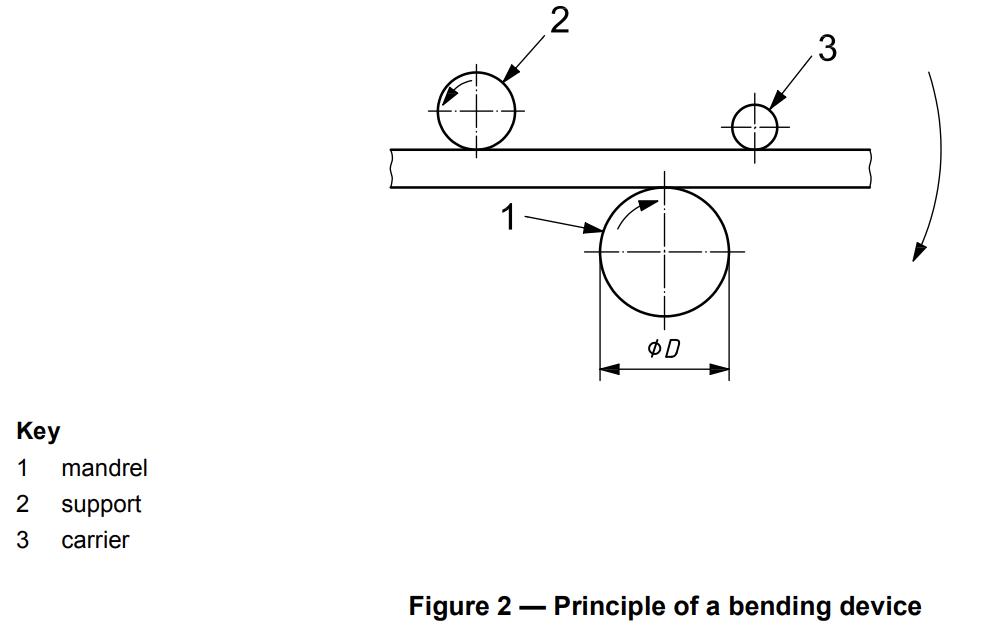

6.2.1 A bending device, the principle of which is shown in Figure 2, shall be used.

NOTE Figure 2 shows a configuration where the mandrel and support rotate and the carrier is locked. It is also possible that the carrier rotates and the support or mandrel is locked.

6.2.2 The bend test may also be carried out by using a device with supports and a mandrel (e.g. see ISO 7438).

6.3 Test procedure

The bend test shall be carried out at a temperature between 10 °C and 35 °C, unless otherwise agreed by the parties involved.

For testing at a low temperature, if the agreement does not specify all the testing conditions, a deviation of ±2 °C on the agreed temperature should be applied. The test piece should be immersed in the cooling

medium for a sufficient time to ensure that the required temperature is reached throughout the test piece (for example, at least 10 min in a liquid medium or at least 30 min in a gaseous medium). The bend test should start within 5 s from removal from the medium. The transfer device should be designed and used in such a way that the temperature of the test piece is maintained within the temperature range.

The test piece shall be bent over a mandrel.

The angle of bend (γ) and the diameter of the mandrel (D) shall be in accordance with the relevant product standard.

6.4 Interpretation of test results

The interpretation of the bend test shall be carried out in accordance with the requirements of the relevant product standard.

If these requirements are not specified, the absence of cracks visible to a person with normal or corrected

vision is considered as evidence that the test piece withstood the bend test.

A superficial ductile tear may occur at the base of the ribs or indentations and is not considered to be a failure.

The tear may be considered superficial when the depth of the tear is not greater than the width of the tear.

7 Rebend test

7.1 Test piece

The general provisions given in Clause 4 apply.

7.2 Test equipment

7.2.1 Bending device

A bending device as specified in 6.2 shall be used.

7.2.2 Rebending device

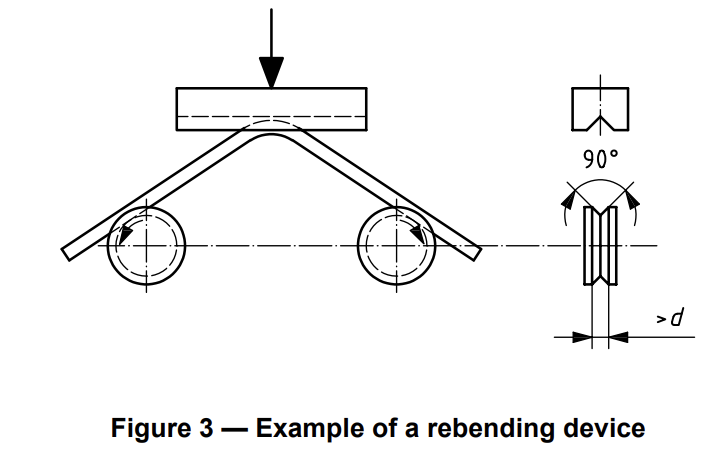

Rebending can be performed on a bending device as shown in Figure 2. An example of an alternative

rebending device is shown in Figure 3.

7.3 Test procedure

7.3.1 General

The test procedure consists of three steps:

a) bending;

b) artificial ageing;

c) rebending.

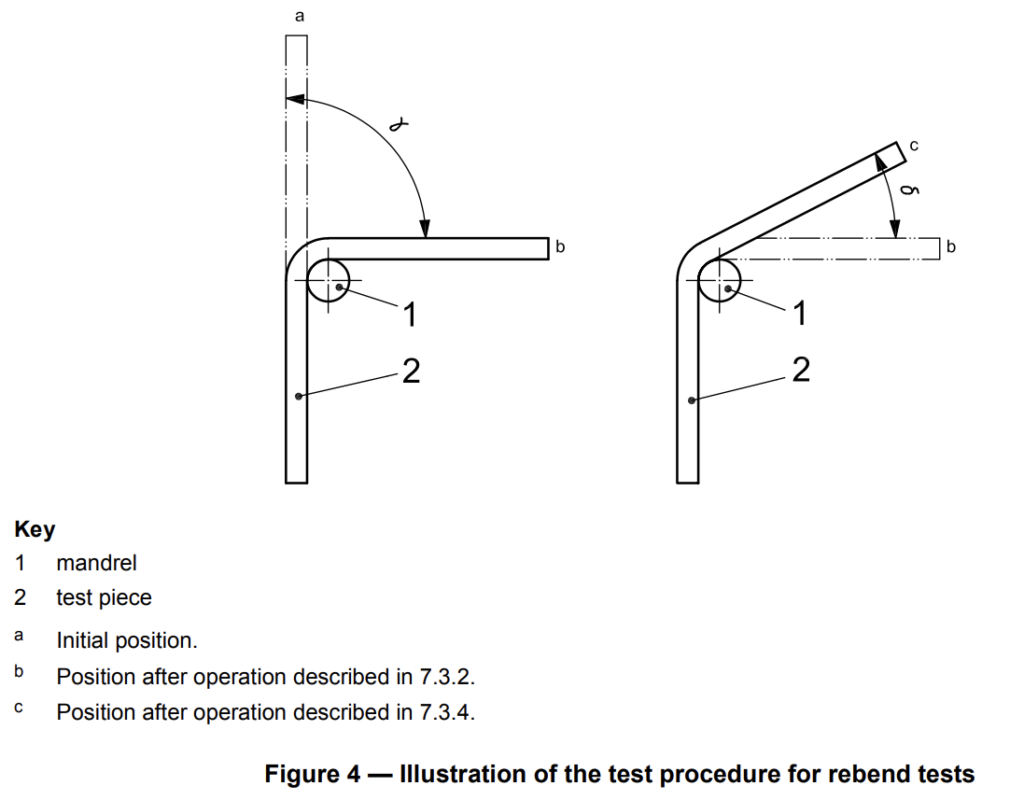

The test procedure is illustrated in Figure 4.

7.3.2 Bending

Bending shall be performed at a temperature between 10 °C and 35 °C. The test piece shall be bent over a

mandrel.

The angle of bend (γ) and diameter of mandrel (D) shall be in accordance with the relevant product standard.

The test piece shall be carefully inspected for cracks and fissures visible to a person with normal or corrected vision.

7.3.3 Artificial ageing

The temperature and time of artificial ageing shall be in accordance with the relevant product standard.

If the product standard does not specify any ageing treatment, the conditions specified in Clause 4 should be applied.

7.3.4 Rebending

After free cooling in still air to a temperature between 10 °C and 35 °C, the test piece shall be bent back by a specified angle (δ) in accordance with the relevant product standard.

7.4 Interpretation of test results

The interpretation of the rebend test shall be carried out in accordance with the requirements of the relevant product standard.

If these requirements are not specified, absence of cracks visible to a person with a normal or corrected vision is considered as evidence that the test piece has withstood the rebend test.

A superficial ductile tear may occur at the base of the ribs or indentations and is not considered to be a failure.

The tear may be considered superficial when the depth of the tear is not greater than the width of the tear.

Bend-Rebend Tester of Rebar- 32mm- ISO15630-1

- According to ISO 15630-1

- Easy operation

- Digital display of angle

- Digital set for bend and rebend angle

- Range of diameter: 6-32mm (other sizes on request)

- Angle of bend and rebend: 0-180 degrees

- Rotational speed about 1.4 r/min

- Power: 3p-380V-50Hz-5KW

- Protect cover for the operator

- Easy replacement of mandrels

- Easy set of holding arm position for the rebar

- Easy test of bend and rebend on the rotating table setup

- Weight is about 800 Kg

- Mandrels sizes according to customer request