38. Stiffness of Fabric

38.4 Apparatus:

38.4.1 CRE-Type Tensile Testing Machine.

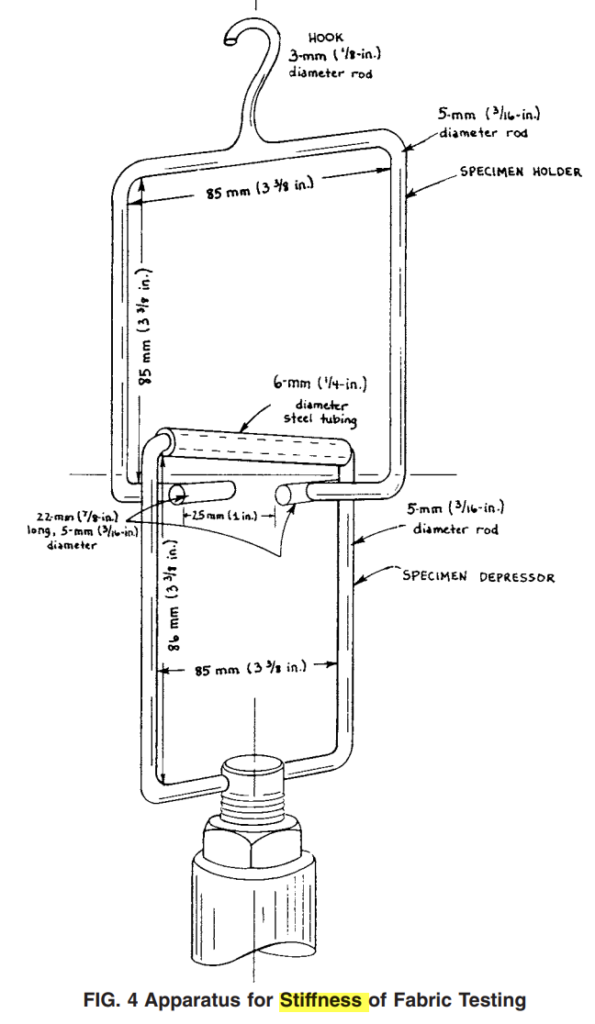

38.4.2 Loading Cell, 20 N (2000 gf).

38.4.3 Specimen Holder—An 85-mm (33⁄8-in.) square frame made of 5-mm (1⁄4-in.) diameter steel rod. In the middle of one side is a hook made of 3-mm (1⁄8-in.) rod diameter for connecting the holder to the loading cell. In the middle of the opposite side, there is a 22-mm (7⁄8-in.) long, 5-mm (1⁄4-in.) diameter rod fastened at midpoint and at right angles to the side of the frame. These two “T’s,” 25-mm (1-in.) apart, form a rack on which the test specimens lay across the 25-mm (1-in.) opening (see Fig. 4).

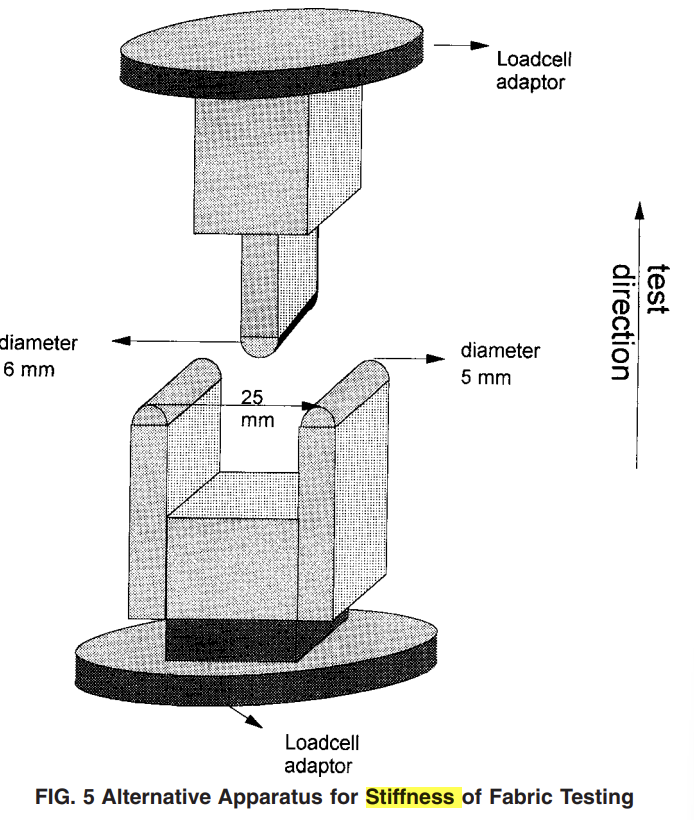

38.4.3.1 For CRE-type tensile testing machines, which are able to measure under compression, a 3-point bending fixture with a distance between the lower rollers of 25-mm (1-in.) can be used in place of the above described specimen holder. The lower rollers have a radius of 5-mm (1⁄4-in.) and the upper roller has a radius of 6-mm (1⁄4-in.) (see Fig. 5).

38.4.4 Specimen Depressor, 85-mm (33⁄8-in.) square frame, made of 5-mm (1⁄4-in.) diameter steel rod, rigidly fastened with a threaded connector to the lower crosshead. The side opposite the crosshead connection is covered with a 6-mm (1⁄4-in.) diameter piece of steel tubing. This forms a bar, which presses against specimens to bend them during the test (see Fig. 4).

38.5 Number of Specimens:

38.5.1 Test the number of specimens such that the user may expect at the 95 % probability level that the test result is no more than 3.50 % of the average above or below the true average (that is, a theoretical average obtained from an infinite number of observations). Determine the number of specimens in accordance with Practice D 2258.

38.6 Specimen Preparations:

38.6.1 Cut each 50-mm (2-in.) specimen of fabric to contain 16 ends. Select specimens that are as straight as possible. Do not preflex specimens before testing. Remove three ends from each edge of each specimen, leaving ten warp ends and all the filling in the sample.

38.7 Procedure:

38.7.1 Mount the specimen holder and depressor in the testing machine, calibrate, and set the tester at zero.

38.7.2 Adjust the crosshead with the presser bar of the depressor approximately 6-mm (1⁄4-in.) above the opening in the specimen rack.

38.7.3 Set the crosshead speed at 25-mm/min (1-in./min) and the chart speed at 125-mm/min (5-in./min). Set the load selector for the minimum scale force to accommodate the specimen and for the bending force to occur between 10 and 90 % of full-scale force, preferably at mid-scale. 38.7.4 Place the specimen on the rack with the middle of the specimen at the midpoint of the rack and the longitudinal axis of the specimen parallel to the 25-mm (1-in.) opening.

38.7.5 Start the tester to lower the crosshead and pull the presser bar onto the specimen and through the opening in the specimen rack.

38.7.6 Record the maximum force required to pull the specimen through the opening to the nearest 1 mN (0.1 gf).

38.8 Calculation:

38.8.1 Calculate the average stiffness results for the sample to the nearest 1 mN (0.1 gf).

38.9 Report:

38.9.1 State that the specimens were tested as directed in Section 38 of Test Methods D 885. Describe the material or product sampled and the method of sampling used.

38.9.2 Report the option or procedure used, the number of specimens tested, and the fabric stiffness for the sample.

Stiffness Tester for Fabric According to ASTM D885

- USB connection to computer

- computer is as option

- software is included

- Windows 7,8,10 based software

- Recording the force

- Reporting in MS EXCEL

- Max force as per customer request (Basic model is 2Kgf)

- Ball screw mechanism

- Step motor activated

- Grip for fabric stiffness test as per ASTM D885

- Fully computer controlled