6 Apparatus

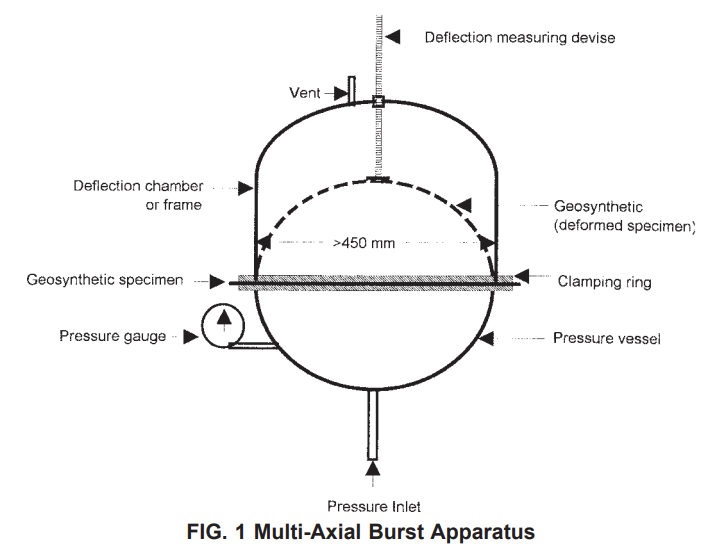

6.1 Fig. 1 shows an example of the test apparatus that can be used in the performance of this test method. The apparatus requires a pressure vessel rated to a minimum of 690 kPa (100 psi). The vessel diameter should be 600 mm3. Other size vessels may be used but it is up to the user to establish correlation to the standard size vessel.

6.2 If the vessel has a deflection chamber it should not inhibit the geosynthetic from freely deflecting during the test. The deflection chamber shall be vented.

6.2.1 Some materials will expand laterally beyond the diameter of the pressure vessel and may contact the sides of the deflection chamber. In these cases, the test is no longer valid and a different device must be used. Devices without deflection chambers have worked well in these situations.

6.3 The vessel will have a system to measure pressure and the magnitude of central deflection.

6.3.1 The system for measuring deflection shall be capable of being read to an accuracy of 5 mm.

6.3.2 The system for measuring pressure shall be capable of being read to an accuracy of 3.5 kPa.

6.4 All test shall be conducted at standard laboratory temperatures of 23 ± 2°C.

7 Test Specimen

7.1 Do not use test specimens with defects or any other abnormalities, unless this is the item of interest.

7.2 Cut the test specimen larger than the area of the main sealing force of the vessel.

7.3 If a permeable material such as a geotextile is being tested, an impermeable material such as a geomembrane or thin plastic sheet has to overlay the permeable material to maintain the pressure in the vessel during the test.

7.3.1 When testing permeable materials, the impermeable material shall be more elastic than the permeable material (unless the combination of the two materials is the desired test variable). This is required so that the permeable material fails first.

7.3.2 Test results on permeable materials will be affected by the impermeable material used in the test.

7.4 Test three replicate specimens on each sample unless otherwise noted.

8 Procedure

8.1 Cut the test specimen to the requirements of the test vessel to ensure a good seal. Place specimen across the opening of the vessel. Be sure the specimen is not sagging.

8.2 Be sure the specimen remains flat while the edge of the specimen is being securely clamped into place.

8.3 Either air or water can be used to pressureize the vessel. If a water system is used, introduce water into the vessel until it is completely filled.

8.4 Add water or air into the system so as to control the rate of centerpoint deflection at 20 mm/min in a continuous fashion.

8.4.1 Stepwise increments of center point deflection are not allowed.

8.5 Record the amount of centerpoint deflection and pressure at least every 10 s.

8.6 Continue with the test by maintaining a constant rate of centerpoint deflection at the specified rate until the specimen has ruptured (as noted by a sudden loss in pressure) or until some predetermined end point has been reached.

NOTE 2—The user is cautioned that the sudden release of pressure at rupture could potentially be dangerous and cause either personal injury or damage to the surroundings.

8.7 Repeat the above with two additional specimens from the same sample.

NOTE 3—If the specimen has deformed in a fashion so that the surface of the specimen approximates an arc of a sphere or an ellipsoid, strees-strain calculations are provided in the appendix.