6 Apparatus

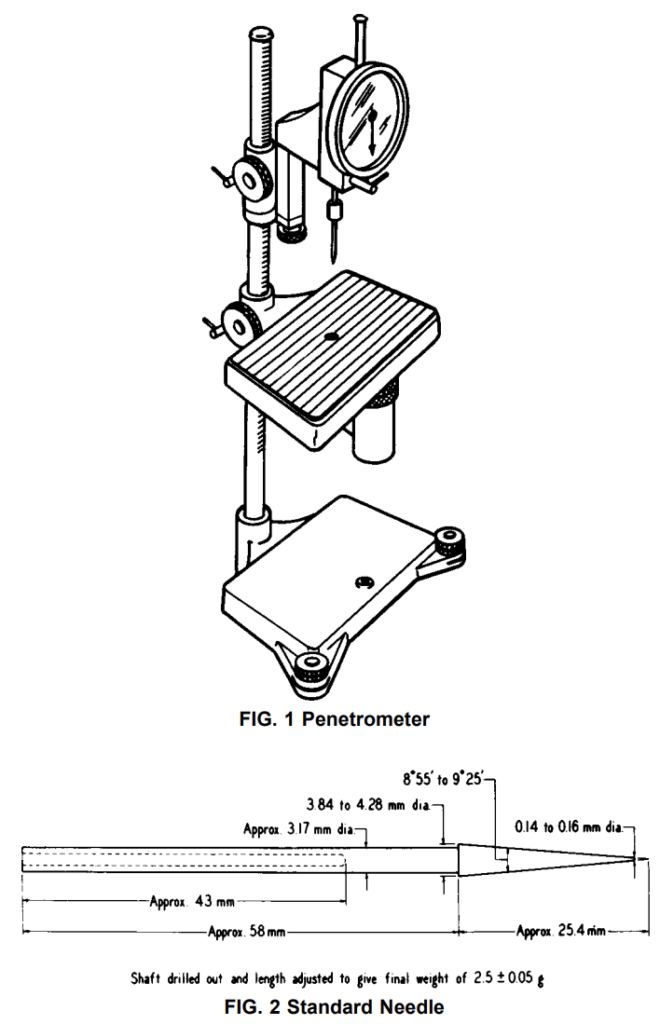

6.1 Penetrometer, for applying the standard needle to the surface of the sample specimen and for measuring the extent of penetration at the conclusion of the test. The penetrometer shall be constructed in such a manner that the accurate placement of the tip of the needle at the level surface of the specimen may be made while maintaining a “zero” reading on the indicator. The apparatus shown in Fig. 1 represents a composite drawing illustrating the two available types of instrument, one with an adjustable table and the other with an adjustable needle assembly; the use of either type instrument is permissible. The loaded needle must fall, when released, without appreciable friction. The instrument shall be provided with leveling screws and a spirit level to maintain the plunger shaft in a true vertical position. The indicator scale shall be calibrated in tenths of a millimetre divisions and shall have a range of at least 250 tenths of millimetres.

6.2 Timing Device—An automatic timing release mechanism attached to the penetrometer may be used. Alternatively, a stop watch graduated in 0.1-s intervals may be used.

6.3 Needle and Plunger—The needle shall be approximately 83 mm in length and conform to the dimensions shown in Fig. 2. It shall be symmetrically tapered at one end to a cone whose angle shall be within the range from 8° 55 min to 9° 25 min over the entire length of the cone. The axis of the cone

shall be coincident with the shaft axis within 0.13-mm (0.005- in.) maximum runout (total indicator reading). The tapered section of the needle shall be made from fully hardened and tempered stainless steel, Grade 440-C or equal, Rockwell hardness C57 to 60. After tapering, the point shall be ground off to a truncated cone, the smaller base of which shall be from 0.14 to 0.16 mm in diameter. The truncation shall be square with the needle axis within 2°, and the edge shall be sharp and free from burrs. The conical surface and the truncation shall be finished to a smoothness of 0.2 µm (8 µin.) (rms). The final weight of the needle shall be 2.5 ± 0.05 g. The total weight of the plunger shall be 47.5 ± 0.05 g; a weight of 50 ± 0.05 g is required for mounting on the plunger.

NOTE 2—The National Institute of Standards and Technology will measure and certify the accuracy of penetration needles in accordance with these permissible variations.

6.4 Test Specimen Container, consisting of a brass cylinder open at both ends, having a 25.4-mm (1-in.) inside diameter, 31.8-mm (11⁄4-in.) height, and 3.2-mm (1⁄8-in.) wall thickness. To prevent slippage of very hard wax, a few screw threads or grooves shall be cut into the center part of the inside wall of the cylinder. The cylinder shall be placed on a base plate of brass, wetted with an equal volume mixture of glycerin and water, when casting a test specimen.

6.5 Test Room or Cabinet, capable of being maintained at 23.9 ± 2.2°C (75 ± 4°F).

6.6 Water Bath, of at least 10-L capacity capable of being maintained at the test temperature within ±0.1°C (60.2°F) (Note 6). The water bath should be made of glass or have a window to permit a horizontal view of the specimen. It shall be possible to immerse the test specimen in the bath to a depth of not less than 102 mm (4 in.) and to support it on a perforated conditioning shelf not less than 51 mm (2 in.) from the bottom of the bath. The bath also shall be equipped with a rigid perforated test shelf about 51 mm below the water level to support the specimen during the penetration by the needle.

6.7 Thermometer, for use in the water bath. An ASTM Precision Thermometer, total immersion, having a range from 25 to 55°C or 77 to 131°F and conforming to the requirements for Thermometer 64C or 64F as prescribed in Specification E 1.

6.8 Brass Plate, 63.5 by 38 by 6.4 mm (21⁄2 by 11⁄2 by 1⁄4 in.) for supporting test specimen during preparation of the sample. The specimen support is placed on corks during the cooling period.

7 Preparation of Test Specimen

7.1 Heat the wax sample to approximately 17°C (30°F) above its congealing point (as determined by Test Method D 938), using care to prevent local overheating. Stir until the sample is homogeneous and free from air bubbles. In the test room or cabinet maintained at 23.9 ± 2.2°C (75 ± 4°F), place the brass plate on two corks (No. 16 or 18 recommended) and wet the upper surface of the plate with a mixture of equal volumes of glycerin and water. Place the test specimen container on the plate and then pour the melted wax into it in such a way that a convex meniscus is formed. Allow the container and contents to cool in the room at 23.9 ± 2.2°C for 1 h. Then shave any excess wax from the top of the container and remove the brass plate. Place the smooth wax surface up. Condition the specimen in the bath at the test temperature within 0.1°C (60.2°F) for 1 h.

NOTE 3—Very hard waxes occasionally will shrink away from the walls of the test specimen container; in such cases, it is permissible to wedge the specimen in the container.

8 Procedure

8.1 Reverse the penetrometer base and place the penetrometer head over the edge of the water bath and above the perforated test shelf used for supporting the specimen. It may be necessary to place a weight on the base of the penetrometer to counter-balance the head (Note 5). Level the penetrometer and the perforated shelf in the water bath.

NOTE 4—Alternatively, the penetrometer may be placed in the water bath. Likewise, a small bath may be placed on the penetrometer stand provided the test temperature (within 0.1°C (60.2°F)) and the required water circulation above and below the test specimen are maintained and provided further that the temperature of the small bath is measured immediately before testing each specimen using the thermometer specified in 6.7. Emergent stem corrections shall be applied when the correction equals or exceeds 0.05°C (0.1°F). One of the above alternatives will be required if the penetrometer is the adjustable table type.

8.2 Place the specimen container on the perforated test shelf with the smooth wax surface that had contacted the brass plate at the top. Make certain that the container or test shelf cannot teeter during testing. Adjust the water level so that it is 25 mm (1 in.) above the top surface of the specimen and maintain it at the test temperature.

NOTE 5—The test may be performed at any temperature in the range from 25 to 55°C (77 to 130°F). Temperatures 25, 35, 45, or 50°C (77, 95, 113, or 122°F) normally are used.

8.3 Place a 50-g weight above the penetrometer needle, making a total load of 100 ± 0.15 g for the needle and all attachments. Observe that the release mechanism does not drag on the shaft and that the indicator on the scale is in the “zero” position. Adjust either the indicator assembly or the table, depending upon the type of instrument, until the tip of the needle nearly touches the surface of the specimen. Securely lock the movable assembly in this position.

8.4 Then, by means of the slow-motion adjustment, bring the needle tip to just touch the surface of the specimen, watching the reflection of the needle tip as an aid to accurate setting. After 5 min, release the needle shaft and hold it free for 5 s, timing this interval automatically or with a stop watch graduated to 0.1 s (Note 6). Then gently depress the indicator shaft until it is stopped by the needle shaft and read the penetration from the indicator scale.

NOTE 6—If an automatic timing release mechanism is not used, the timing can be done conveniently by starting the stopwatch before the beginning of the test, releasing the needle shaft as the second hand crosses a unit graduation of the watch, and engaging the shaft of the needle when the watch indicates exactly 5 s later.

8.5 Make four tests at points about equally spaced (not less than 12.7 mm (1⁄2 in.) apart) on a circumference at least 3.2 mm (1⁄8 in.) from the side of the container. Before each test, wipe the needle carefully toward its point with a clean, dry cloth to remove all adhering wax, position the needle as described in 8.4, and proceed with the test.

Needle Penetration Tester for WAX

- According to standard ASTM D 1321

- Digital timer

- Stirrer for water bath temperature homogeneity

- Penetrometer according to ASTM D1321

- 83mm needle according to standard

- 25.4-mm inside diameter brass cylinder sample cup

- Digital display of needed movement

- Flange-type heating element guarantees easy replacement

- Water bath with a window to see the sample horizontally

- Water bath of 10 L capacity

- 63.5 by 38 by 6.4 mm brass plate for supporting specimen during penetration

- PID temperature control of water bath with resolution of 0.1 °C

- Needle material is stainless steel

- Needle and sample cup as per standard

- Water bath temperature up to 80 °C

- Training video included