15 Method E11: Bend

15.1 Object

The purpose of this test is to determine the ability of an optical fibre cable or cable element to withstand bending around a test mandrel.

NOTE This test may be utilized at any specified temperature, including the low or high temperature limits for the cable.

15.2 Sample

The sample shall be terminated at each end in a manner such that the fibres, sheath(s) and any strain members are clamped together in a representative manner, or the sample may be long enough that no restraint is needed.

15.3 Apparatus

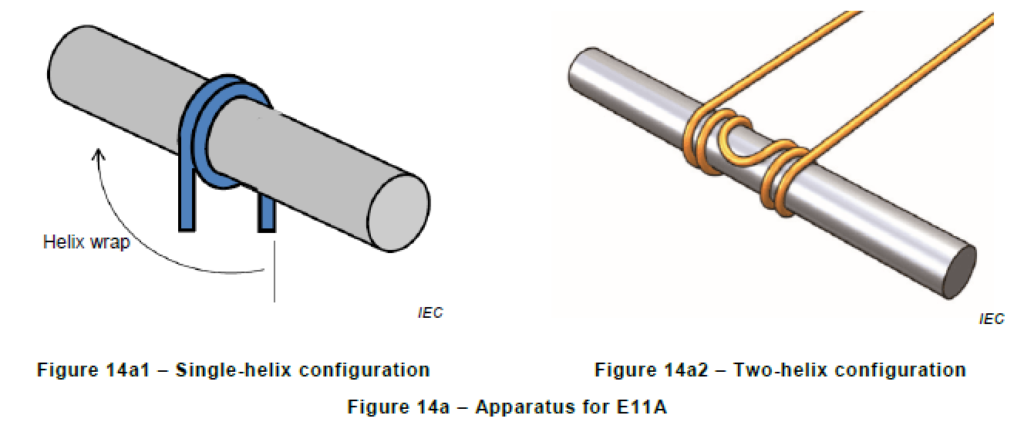

A single mandrel apparatus shall enable the sample to be wrapped tangentially in a close helix around a test mandrel. See Figure 14.

15.4 Procedure

As indicated in the detail specification, one of the following procedures shall be used.

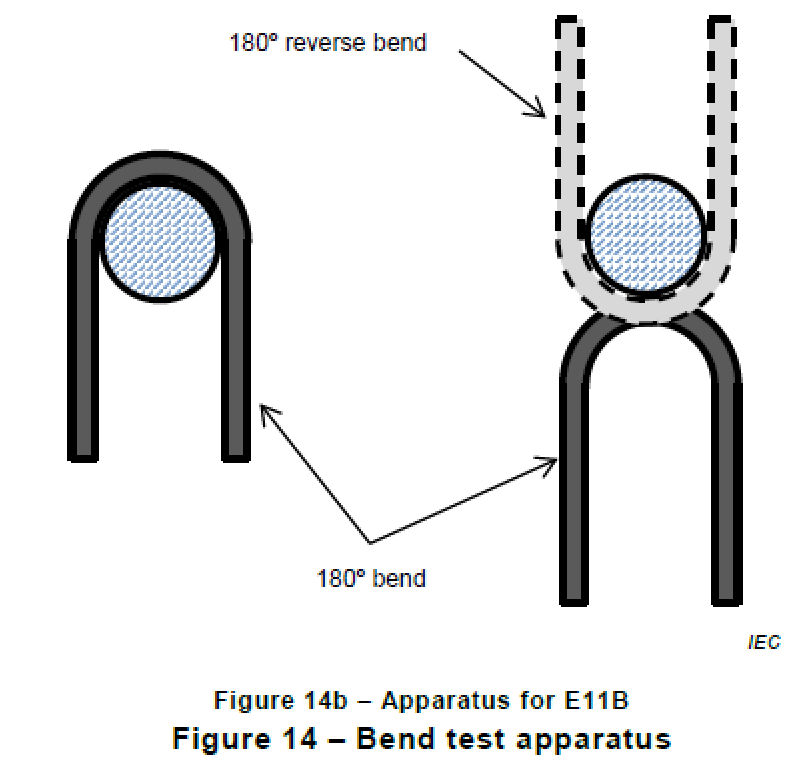

15.4.2 Procedure 2 – Test method E11B (alternative test procedure) The sample shall be bent around a mandrel through 180° and kept taut during the bending. A cycle consists of one U bend followed by a reverse U bend, and a return to the straight position. The diameter of the test mandrel and the number of cycles shall be stated in the detail specification.

The test shall be carried out at the specified temperature.

15.5 Requirements

The acceptance criteria for the test shall be as stated in the detail specification. Typical failure modes include loss of optical continuity, degradation of optical transmittance or physical damage to the cable.

15.6 Details to be specified

The detail specification shall include the following:

a) procedure to be used (procedure 1 or procedure 2);

b) test mandrel diameter (or ratio of mandrel diameter to cable diameter);

c) number of cycles;

d) number of turns in the helix (for procedure 1);

e) maximum allowable attenuation increase:

– during the test (if applicable),

– after the test (if applicable);

f) test temperature, e.g. ambient, low, and/or high, as appropriate.