4 Principle

A test specimen is weighed and subsequently calcinated at a defined temperature. The specimen is then

reweighed and the non-combustible matter content (glass + filler) obtained by determining the difference in mass of a test specimen before and after calcination in one of the following ways:

a) In the case of materials containing no fillers the glass content is calculated directly from the difference in mass (method A);

b) In the case of materials containing both glass and filler, the glass and filler remaining after calcination are separated by dissolution of the filler in hydrochloric acid. The difference between the mass of the specimen before calcination and the mass of the dried specimen after reaction with acid is used to measure the glass content. The filler content is obtained by calculating the difference between the mass of the specimen after calcination and the mass of the dried specimen after reaction with acid (method B).

The test method requires that all weighings be made at constant mass after repeated calcination and/or drying. In those cases where known materials are being tested regularly, a minimum time for the calcination and drying stages may be determined by experiment to ensure that constant mass has been reached.

NOTES:

1 If the material tested contains a resin which is combustible under the test conditions and/or fillers which do not degrade by calcination, then the loss on ignition is equal to the resin content. It should be noted that the resin content calculated in this way includes the combustible part of the other components in the composition (glass size, Pigments, etc.) but this is usually small compared to the resin content.

2 In those cases where fillers are present that are degraded at the test temperature, it is not possible to obtain an accurate determination of the glass, resin or filler content.

6 Preparation of test specimens

The test specimen shall be fully representative of the piece or batch examined. They shall be obtained in accordance with clause 5.

Unless otherwise specified, it is recommended that the specimens be tut out in a shape which allows them to fit into a silica boat or porcelain crucible. The mass of each specimen shall be within the range:

2 g to 20 g for prepregs and moulding compounds;

2 g to 10 g for laminates.

For each test result, use a minimum of two specimens (see 5.1).

In the case of prepregs and moulding compounds which contain solvents or free monomer, care shall be taken to avoid loss of volatile matter. For SMC, the protective release film shall not be removed from the laboratory Sample or the test specimen until just before commencing the test procedure. All prepreg and moulding-compound laboratory samples, including SMC, shall be sealed in a vapourproof plastic bag immediately after the laboratory Sample has been taken.

7 Determination

The choice of method used to determine the glass and filler content will depend on the presence or absence of filler. The methods described in this International Standard are

Method A: for the determination of the glass content when no fillers are present.

Method B: for the determination of the glass and filler content when both components are present.

7.1 Method A

7.1.1 Reagents

No reagents are required for method A.

7.1.2 Apparatus

Normal laboratory apparatus, plus the following:

7.1.2.1 Balance, graduated to 0,l mg.

7.1.2.2 Silica boat or porcelain crucible, of a suitable size to contain a specimen.

7.1.2.3 Muffle furnace, located under a ventilated hood and capable of maintaining the Chosen temperature (see 7.1.3.2) to within ± 20 C.

7.1.2.4 Desiccator, containing a suitable drying agent (e.g. silica gel).

7.1.2.5 Ventilated drying oven, set at 105 C ± 3 C.

7.1.3 Procedure

For each specimen, proceed as follows:

7.1.3.1 Preparation of the boat or crucible

Weigh the clean, dry boat or crucible (7.1.2.2) to the nearest 0,l mg on the balance (7.121). Place in the muffle furnace (7.123) set to the Chosen temperature (see 7.1.3.2) and leave for 10 min. After cooling to ambient temperature in the desiccator (7.124) verify that the mass has not changed. If there has been a Change, repeat these operations until constant mass is reached.

7.1.3.2 Calcination

Weigh the clean, dry boat or crucible, prepared as indicated in 7.1.3.1. Record the mass in grams as ml. Place a specimen in the boat or crucible and dry in the ventilated drying oven (7.125) at 105 C to constant mass. Cool to ambient temperature in the desiccator and reweigh. Record the mass in grams as m2. In the case of specimens which contain volatile matter, care is needed to avoid loss of the volatile matter. Omit the drying Stage therefore. Remove the specimen from the vapourproof bag and remove any release film. Place the specimen in the boat or crucible, weigh and record the mass in grams as m6.

Place the boat or crucible containing the test specimen in the muffle furnace, preheated to a temperature of 625 C and h eat to constant mass.

For reinforced products with glass or filler which will not withstand this calcination temperature, a temperature between 500 C and 600 C may be used, in accordance with the specification for the glass or filler. lt is essential to maintain the Chosen temperature constant to & 20 C.

Allow the boat or crucible, together with the residue, to cool in the desiccator to ambient temperature and reweigh. Record the mass in grams as m3.

7.1.4 Expression of results

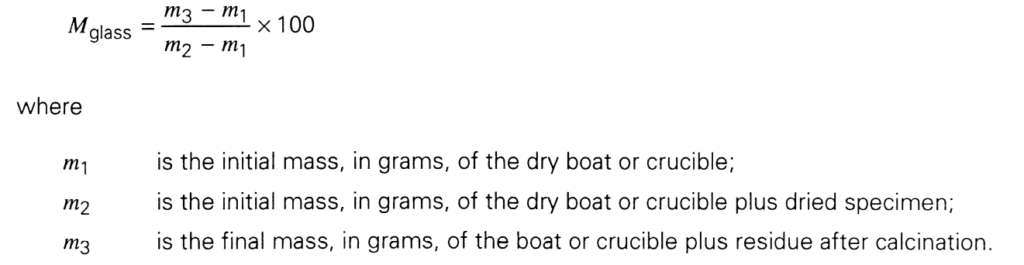

Calculate, for each specimen, the glass content M_glass, expressed as a percentage of the initial mass, using equation (1):

In the case of specimens containing volatile matter, when the drying Stage was omitted, replace m2 in equation (1) by mg, where m6 is the initial mass, in grams, of the dry boat or crucible plus undried test piece.

If the results of the individual measurements differ by more than 5 % in relative value, carry out an additional determination on a third specimen taken from the same location in the elementary unit or laboratory Sample.

Express the result of the test as the average of the two (or three) individual measurements.

7.2 Method B

7.2.1 Reagents

The following reagents are required for method B.

7.2.1.1 Hydrochloric acid, 35 % (VIV) concentration, commercial grade.

7.2.1.2 Denatured ethanol.

7.2.1.3 Chromic acid mixture, for cleaning.

The recommended composition of the mixture is 7 % sodium dichromate in concentrated sulfuric acid.

7.2.2 Apparatus

The apparatus given in 7.1.2, plus the following:

7.2.2.1 40 mm diameter sintered-glass filter, porosity P 160, i.e. 100 µm to 160 µm (see ISO 4793).

7.2.2.2 250 ml beaker.

7.2.2.3 Suction flask.

7.2.2.4 Glass rod.

7.2.2.5 Tweezers.

7.2.3 Procedure

For each test specimen, proceed as follows:

7.2.3.1 Preparation of boats or crucibles

Follow the procedure given in 7.1.3.1.

7.2.3.2 Preparation of sintered-glass filter

Before each test, clean the sintered-glass filter (7.2.2.1) by soaking in the chromic acid mixture (7.2.1.3). Place the filter on the suction flask (7.2.2.3), apply the suction, and rinse the filter first with warm water, then with denatured ethanol (7.2.1.2). Dry the filter in the drying oven (7.1.2.5) to constant mass. Record the mass in grams as m4.

7.2.3.3 Calcination

Follow the procedure given in 7.1.3.2.

7.2.3.4 Separation of glass and filler when filler completely dissolves in hydrochloric acid

Separate the filler from the glass as follows:

Place into the 250 ml beaker (7.2.2.2), 5 ml of hydrochloric acid (7.2.1.1) per gram of residue remaining in the boat or crucible after calcination.

Using the glass rod, slowly add the residue in the boat or crucible to the acid in the beaker. Stir carefully to ensure that all the residue has reacted with the acid, taking care that the effervescence caused by the acid reacting with the carbonate fillers does not cause droplets to spit out of the beaker.

When the effervescence finished, three-quarters fill the boat or crucible with water and pour it all into the 250 ml beaker, repeating if necessary until all the residue has been transferred to the beaker.

Add an additional 50 ml of water to the beaker.

Place the filter, dried ar)d weighed as described in 7.2.3.2, on the suction flask and apply the suction.

Slowly pour the acid over the glass on to the filter.

Rinse the glass in the beaker with water and pour the water on to the filter; then rinse with denatured alcohol, agitating with a glass rod, and pour alcohol on to the filter.

Repeat this operation four or five times until the glass is thoroughly clean.

Transfer the glass on to the filter using the glass rod and a jet of denaturated ethanol.

Rinse twice with denaturated ethanol.

Dry the filter to constant mass in the drying oven.

Allow to cool in the desiccator to ambient temperature and weigh. Record the mass in grams as m5.

Alternatively, if the fibre length is greater than 12 mm, the procedure described in informative annex A may be used. The procedure given in 7.2.3.4 shall always be used as the reference method, however.

7.2.3.5 Separation of glass and filler when filler does not completely dissolve in hydrochloric acid

If filler insoluble in hydrochloric acid remains on the filler on filtering, determine the mass m5 as described in 7.2.3.4, continue as follows:

Using tweezers (7.2.2.5), pick out all the glass from the filter. Reweigh the filter with the insoluble filler on it. Record this mass in grams as m7.

NOTE — If the glass filaments are very short, it may not be possible to separate them from the filler manually. In this case, the method given in this International Standard is not capable of giving accurate values of the glass and filler contents separately, although the combined filler and glass content can be determined.

7.2.4 Expression of results

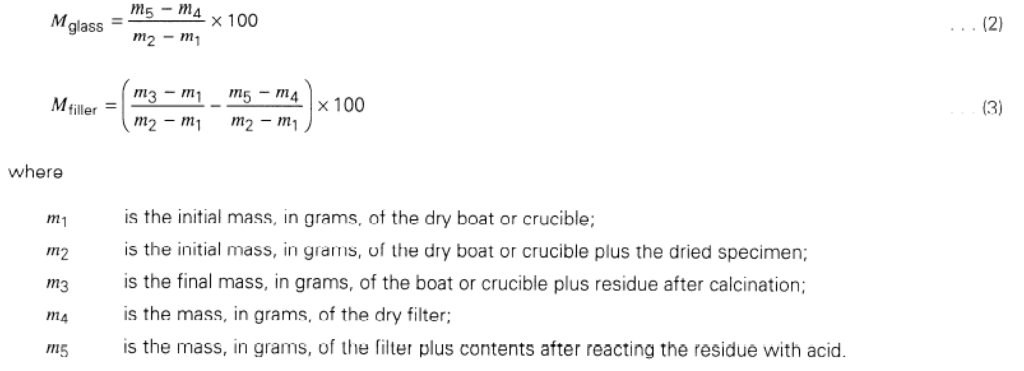

Calculate, for each specimen, the glass content Mglass filler content Mfiller, expressed as a percentage of the initial mass, using equations 2, 3 respectively:

In the case of moulding compounds containing volatile matter, when the drying stage was omitted, replace m2 in the equation by m6, where m6 is the initial mass, in grams, of the dry boat or crucible plus undried test piece.

If filler insoluble in hydrochloric acid remained on the filter on filtering, replace m4 in equations (2) and (3) by m7, where m7 is the mass, in grams, of the dry filter plus undissolved mineral filler.

If the results of the individual measurements differ by more than 5 % in relative value, carry out an additional determination on a third specimen taken from the same location in the elementary unit or laboratory sample. Express the result of the test as the average of the two (or three) individual measurements.