4.2 Apparatus

Forced-air-circulation oven, maintained at 70 °C ± 2 °C, capable of re-establishing that temperature within five minutes after insertion of test pieces.

NOTE — A constant-temperature bath may be used instead of the

oven, provided it has the same thermal capabilities as specified for the oven.

4.3 Test pieces

Five sections of the pipe, preferably taken from different coils, shall constitute the test pieces. Each section shall be about 20d long (d = nominal diameter of the pipe).

NOTE — Shorter lengths may also be used, but are less convenient.

The test pieces shall not initially contain any cracks.

4.4 Procedure

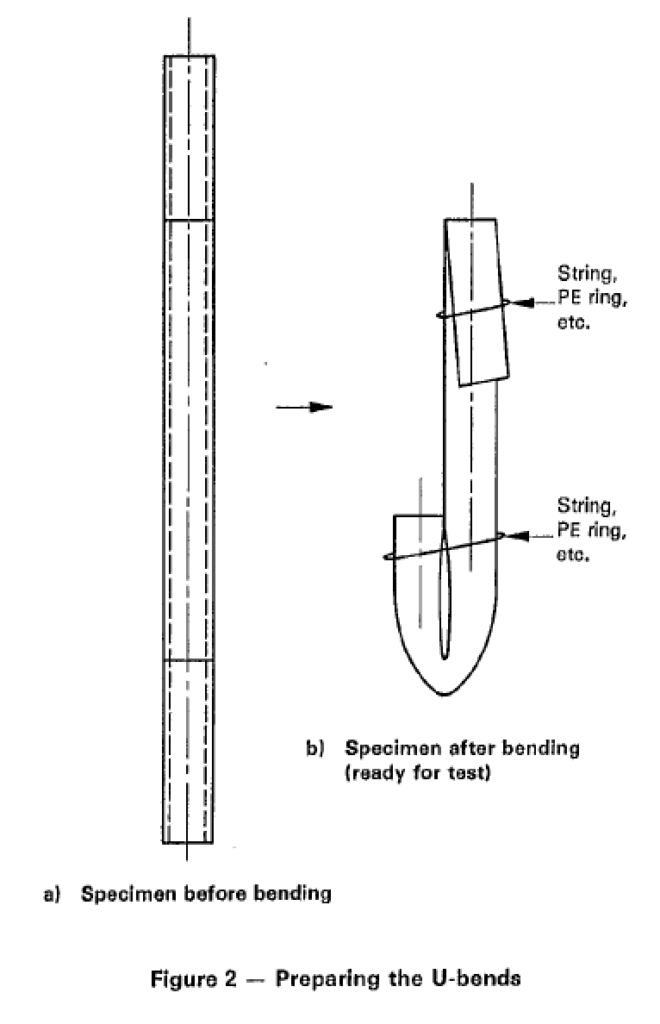

4.4.1 Bend each test piece sharply at two places, forming two U-bends in two different planes perpendicular to each other (see figure 2). The bends shall be located at least 3d away from the ends of the test piece. Each bend is folded back through 180° until both sides of the fold meet, then properly secured to maintain the deformation throughout the test (see figure 2).

4.4.2 Completely coat each bend with the reagent (e.g. by brushing or dipping) and then place all the test pieces in the oven (or immerse them in the bath), taking care not to impose any additional stresses on them.

4.4.3 60 min after the temperature of the oven (bath) has returned to 70 °C ± 2 °C, remove all the test pieces and wipe the bends free of the reagent.

4.4.4 inspect each bend with unaided eye for any kind of visible cracks

4.5 Expression of results

Classify as “failed’ each bend which exhibits at least one visible crack (excluding any crack induced by the object used to secure the bend).

Note the total number of bends which failed according to above definition, evaluating and counting the two bends of each test piece independently.

5 Retest

If one bend failed while nine others did not, repeat the whole procedure with five further test pieces (i.e. ten further bends).

6 Requirements

The pipe is considered to have passed the test if not more than 10 % of the bends tested (Le. 0 out of 10 or a maximum of 2 out of 20) have failed.

Hot Air Oven

- SS304 inner test chamber

- In different capacities like 55, 110, 200, 300, … Litre of internal chamber

- The temperature range is from room temperature up to 250 °C

- Digital PID controller

- Digital timer is included

- Air circulation inside chamber for temperature homogenity