5 Apparatus

5.1 Constant-Temperature Liquid Bath, capable of controlling accurately to ±0.5°C.

5.1.1 The liquid for the bath should not plasticize or react with the specimens. Poly(ethylene glycol), glycerin, and water have been found to have wide applicability.

5.2 Thermometer—ASTM Thermometer 1 °C conforming to the requirements as prescribed in Specification E 1.

5.3 Square Metal Stamp, 100 by 100 mm, with engraved arrow indicating machine direction of film and stamp pad, and ink. (The ink should not be soluble in the bath liquid.)

NOTE 2—A metal die or template (100 by 100 mm) can be used instead of the square metal stamp.

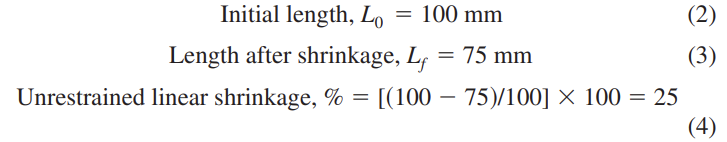

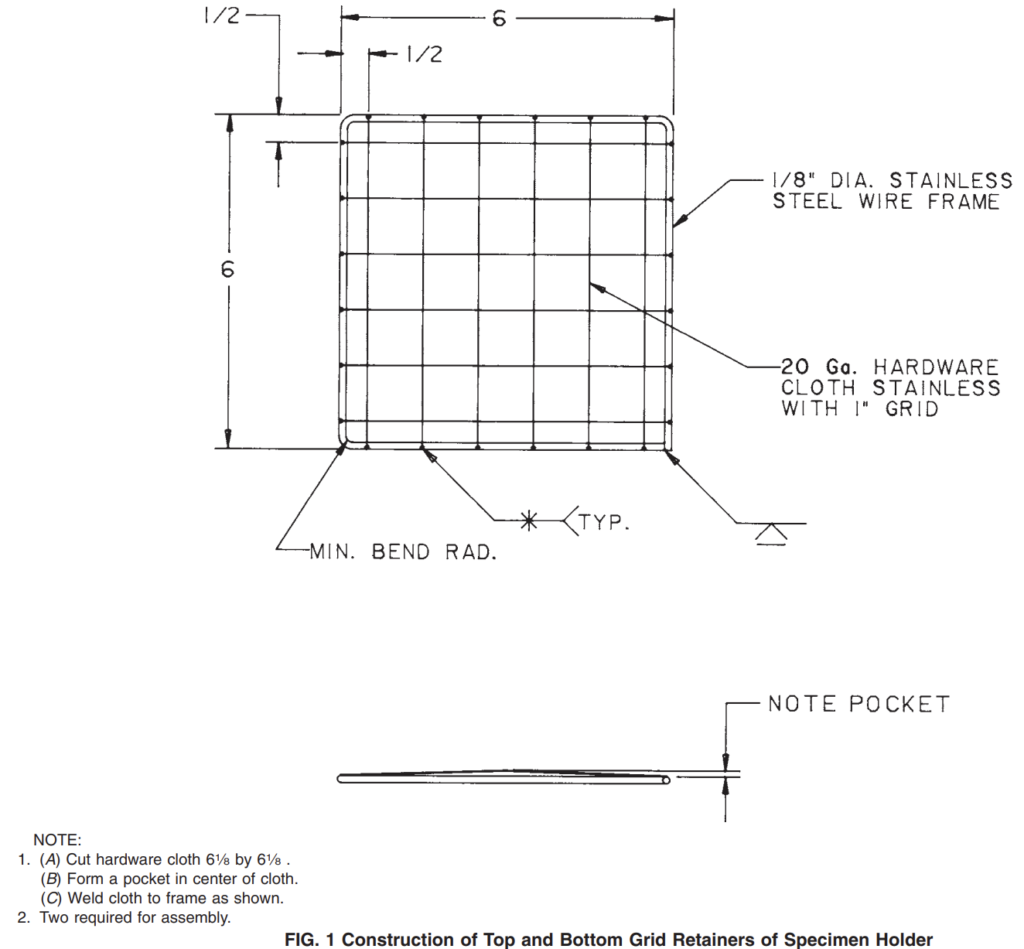

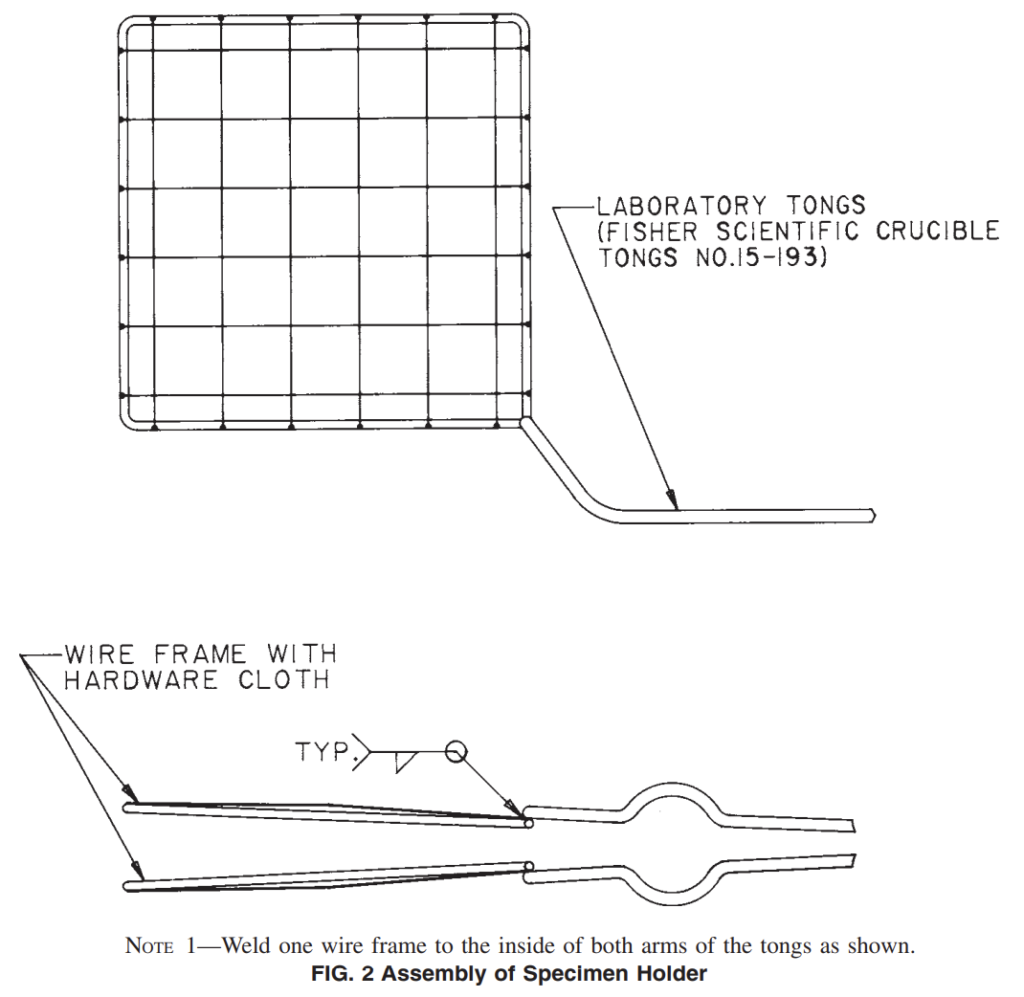

5.4 Free Shrink Holder—A holder designed for test of a single specimen, such as that shown in Fig. 1 and Fig. 2. Alternatively, a holder such as that shown in Fig. 3 may be used to immerse several specimens at a time. However, checks must be made to assure that contact among the specimens does not result in errors.

5.5 Ruler, graduated in millimetres.

6 Test Specimen

6.1 The test specimen shall consist of 100 by 100-mm samples.

6.2 A minimum of two specimens is necessary for each test temperature.

7 Conditioning

7.1 Conditioning—Condition the test specimens at 23 ± 2°C [73.4 ± 3.6°F] and 50 ± 5 % relative humidity for not less than 40 h prior to test in accordance with Procedure A of Practice D 618, for those tests where conditioning is required. In cases of disagreement, the tolerances shall be ±1°C [±1.8°F] and ±2 % relative humidity.

7.2 Test Conditions—Set the liquid bath temperature to within ±0.5°C of the desired temperature and allow to stabilize.

8 Procedure

8.1 Stamp and cut out the stamped section of film. A small border of film may be left around the stamped area.

8.1.1 As an alternative method, the specimens may be cut with a die or with the aid of a template. An edge of the die may be notched to designate film direction.

8.2 Place the specimen in a free shrink holder such that it is free from contact with the edges of the holder. The holder should restrain the specimen from floating in the bath medium while allowing free circulation of the bath medium around the specimen. Multiple specimens can be tested but care should be exercised to prevent restraint between the specimens.

8.3 Observe and record the temperature of the bath before immersion of each specimen.

8.4 Immerse the specimen in the bath for 10 s or a time determined to be sufficient for the material to come to thermal equilibrium and undergo maximum shrinkage. Do not hold the specimen over the bath prior to immersion, as it may result in premature shrinkage or annealing, which may introduce an error.

NOTE 3—Immersion for 10 s has been determined to be generally adequate for most thermoplastics of up to 0.05 mm [0.002 in.] thickness; however, for new or thicker materials, a different time of immersion may be required to ensure maximum shrinkage at the temperature of interest.

8.5 Remove the specimen from the bath and quickly immerse in a liquid medium at room temperature preferably miscible with the bath medium.

8.6 After 5 s remove the specimen from the cooling medium and measure and record the linear dimensions of the specimen in both the machine (longitudinal) and transverse directions.

NOTE 4—Caution: Avoid stretching the specimen.

9 Calculation

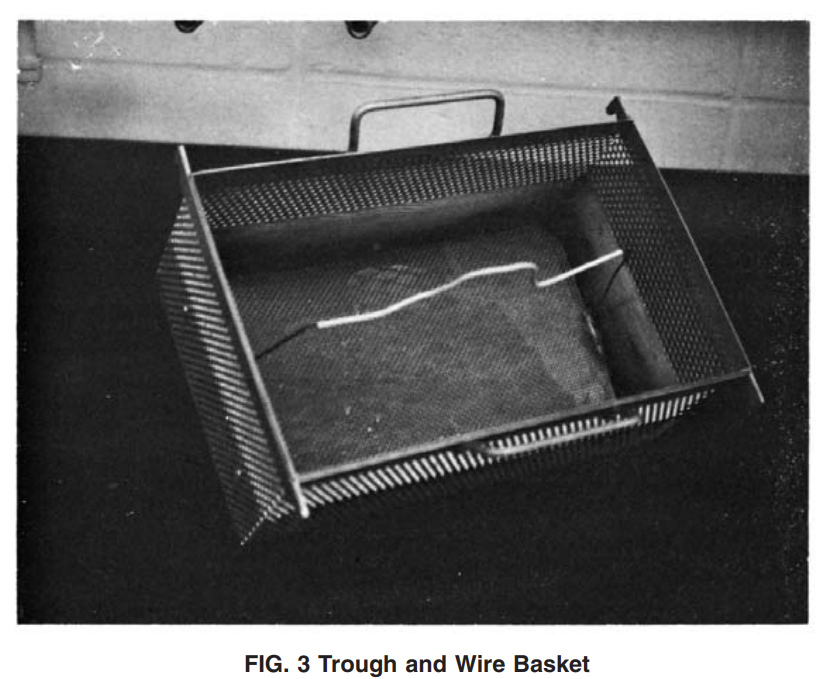

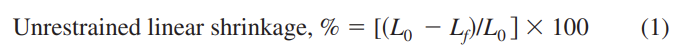

9.1 Determine the percent free shrinkage for each direction as follows:

where:

L0 = initial length of side (100 mm), and

Lf = length of side after shrinking.

NOTE 5—If the material elongates, a negative number will result.

NOTE 6—Since the original dimension is exactly 100 mm, the shrinkage may be read directly from the rule by placing the 100-mm mark on one end of the line and reading millimetres opposite the other end of the line as the percent shrinkage.

9.2 Sample Calculations: