2 Principle

A piece of PVC-U pipe, of specified length, chamfered at one end to an angle dependent on its thickness, is immersed for (30 ± 1) min in dichloromethane, at a temperature T specified by the referring standard, to verify that the PVC-U is not attacked at that temperature. For safety reasons, the surface area of the dichloromethane is kept to the minimum and the dichloromethane is covered by a deep layer of water to reduce evaporation. After immersion in the dichloromethane, the test piece is held in the water layer to allow it to “drip” before final drying and inspection.

NOTE 1 If the PVC-U has not sufficiently gelled, whitening of the surface will occur and, in the worst case, a precipitate will be observed.

NOTE 2 It is assumed that the following test parameters are set by the standard making reference to this International Standard:

a) the temperature T of the dichloromethane (see 4.3 and 6.3);

b) the minimum wall thickness for which the test can be used;

c) the number of test pieces, if appropriate (see 5.1).

3 Reagent

3.1 Dichloromethane, technical grade.

NOTE Technical-grade dichloromethane contains small quantities (at the most, 1 % of each) of chloromethane (CH3Cl), trichloromethane (CHCl3) and tetrachloromethane (CCl4). It has been noted that, even if the level of these impurities reaches 5 % in total, the results are not significantly affected.

WARNING — The boiling point of dichloromethane is low (40 °C). Consequently, it has a high vapour

pressure at ambient temperature. Further, it can be toxic by absorption through the skin and eyes. It is

therefore necessary to take precautions when handling dichloromethane or test pieces which have

been immersed in it. The vapour is also toxic, the threshold limit value (TLV) corresponding to the maximum admissible concentration (MAC) being 100 ml/m3 (ppm). Ventilation of the room or area in which the container is located and where the test pieces are dried is therefore essential.

4 Apparatus

4.1 Chamfering machine (see 5.2).

4.2 Glass or stainless-steel container, of suitable dimensions to accommodate at least one test piece

(see Clause 5), with a grating maintained at a depth approximately 10 mm above the bottom of the container, a lid to limit evaporation of the liquid (see 6.1 and 6.2) and temperature-control equipment, with a stirrer, capable of maintaining the temperature of the liquid at (T ± 0,5) °C with the help of the cooling equipment (4.3).

NOTE It is recommended that a cylindrical container be used of a suitable small diameter, e.g. slightly greater than 315 mm but chosen to suit the dimensions of the most frequently produced pipe size (larger pipes can be cut into a number of longitudinal sections to be fitted into the container, see 5.1).

In laboratories which previously used a larger container for this test, the container specified here can be

placed in the old container, which can be filled with water (see Annex B). Provided the new container is

sufficiently small and made from a heat-conducting material like stainless steel, the temperature-control

equipment and stirrer can be located in the old vessel. The grating shall be designed so it can be positioned at two different levels as follows:

a) with the appropriate parts of the test pieces or test piece sections immersed in the dichloromethane;

b) with the parts of the test pieces or test piece sections which were immersed in the dichloromethane

completely surrounded by water but not in contact with the dichloromethane.

4.3 Cooling equipment, capable of cooling the dichloromethane to the temperature specified in the

referring standard.

4.4 Hood fitted with a fume extraction system, mounted for safety reasons (see warning in Clause 3)

over the container (4.2).

5 Preparation of test pieces

5.1 Cut from the pipe to be tested test pieces 160 mm in length, such that the cut ends are perpendicular to the axis of the pipe. Unless otherwise specified by the referring standard, the number of test pieces shall be three. The wall thickness of the pipe shall be greater than the minimum thickness specified for this test by the referring standard [see item b) of Note 2 to Clause 2].

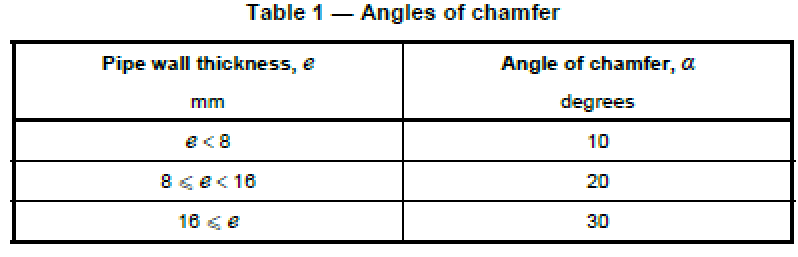

5.2 Chamfer, by cutting (see Note) without producing any appreciable heating effect, one of the ends of

each test piece over its entire wall thickness (see Figure A.1). The angle of chamfer shall be chosen as a

function of the wall thickness of the pipe as specified in Table 1.

NOTE The term “cutting” has been used to exclude grinding.

5.3 If the test pieces are larger than the diameter of the container, cut each test piece into a number of

longitudinal sections. The maximum width of the saw blade used shall be 2,5 mm. The number of sections into which each test piece is cut shall be the lowest possible number, i.e. the maximum possible size, allowed by the size of the container.

5.4 Cool the test pieces or test piece sections to ambient temperature.

6 Immersion conditions

6.1 Fill the container with dichloromethane of known refractive index to a depth sufficient to completely

cover the chamfered zone of the test pieces or test piece sections.

6.2 Cover the dichloromethane with a layer of water preferably 250 mm to 300 mm deep, but not less than 20 mm deep.

6.3 Using the temperature control, cooling equipment and stirrer, establish and maintain the temperature of the dichloromethane in the container at (T ± 0,5) °C [see item a) of Note 2 to Clause 2]. This temperature shall not be less than 12 °C.

6.4 Between tests, add dichloromethane as necessary to maintain the level of the dichloromethane in the

container.

6.5 Ensure that the refractive index of the dichloromethane does not vary during use by more than ± 0,002 from its initial value.

NOTE In practice, the refractive index varies by about 0,000 5 every 3 months if some 700 to 800 tests are carried out per month. A check on the quality of the bath every 3 months should suffice therefore.

7 Procedure

7.1 For the duration of the test, avoid touching the test pieces or test piece sections with the fingers (see

warning in Clause 3), e.g. by using tongs and gloves.

7.2 Place each test piece or test piece section in the liquid so that the chamfered zone is completely

immersed in the dichloromethane.

7.3 Leave the test pieces or test piece sections for (30 ± 1) min in the dichloromethane.

7.4 After this immersion time, raise the grating to the level described in 4.2 b) for 10 min to 15 min to allow the dichloromethane to “drip” from the test pieces or test piece sections (see Figure B.1).

7.5 Remove the test pieces or test piece sections from the container and leave them to dry in the air until

the water has evaporated, but for at least 15 min, in a well-ventilated area or under a hood equipped with a ventilation system.

7.6 Examine the test pieces or test piece sections and determine the result in accordance with Clause 8.

7.7 Repeat the procedure for any remaining test pieces or test piece sections.

8 Expression of results

8.1 If a test piece or the sections making up a test piece show no sign of attack anywhere (other than

swelling), express the result as “No attack”.

Dichloromethane Resistance Tester According to ISO 9852 (METHYLENE CHLORIDE TESTER)

- Compact design with stainless steel inner tank

- Integrated cooling unit (Glass for sample visulization)

- Sample containment cage lift

- Optimised health protection

- Thanks to an isolating water layer above the test medium, effective extraction and optional filter

- Operated via an electronic controller

- Constant test temperatures thanks to highly-efficient water circulation of the test medium and precise temperature control in the inner tank

- Reduction in energy costs thanks to high-quality insulating material

- Digital timer included

- Direct temperature reading of test medium

- Temperature range 10-30 C

- Cooling via integrated cooling unit

- Test fluid

- Approx. 10 l (13 kg) dichloromethane CH2CI2 (nicht im Lieferumfang enthalten) Density at 20 °C: 1,32 – 1,33 g/cm3

- Height of medium level 100mm

- Height of water level approximately 100mm

- Training video included

For more information please check for video in our YouTube channel or ask in WhatsApp: